Coupling braking load limiter

A technology of couplings and load limiters, which is applied in the field of coupling brake load limiters, can solve problems such as machine damage, load limiter single load limiting function, and couplings that cannot be directly applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

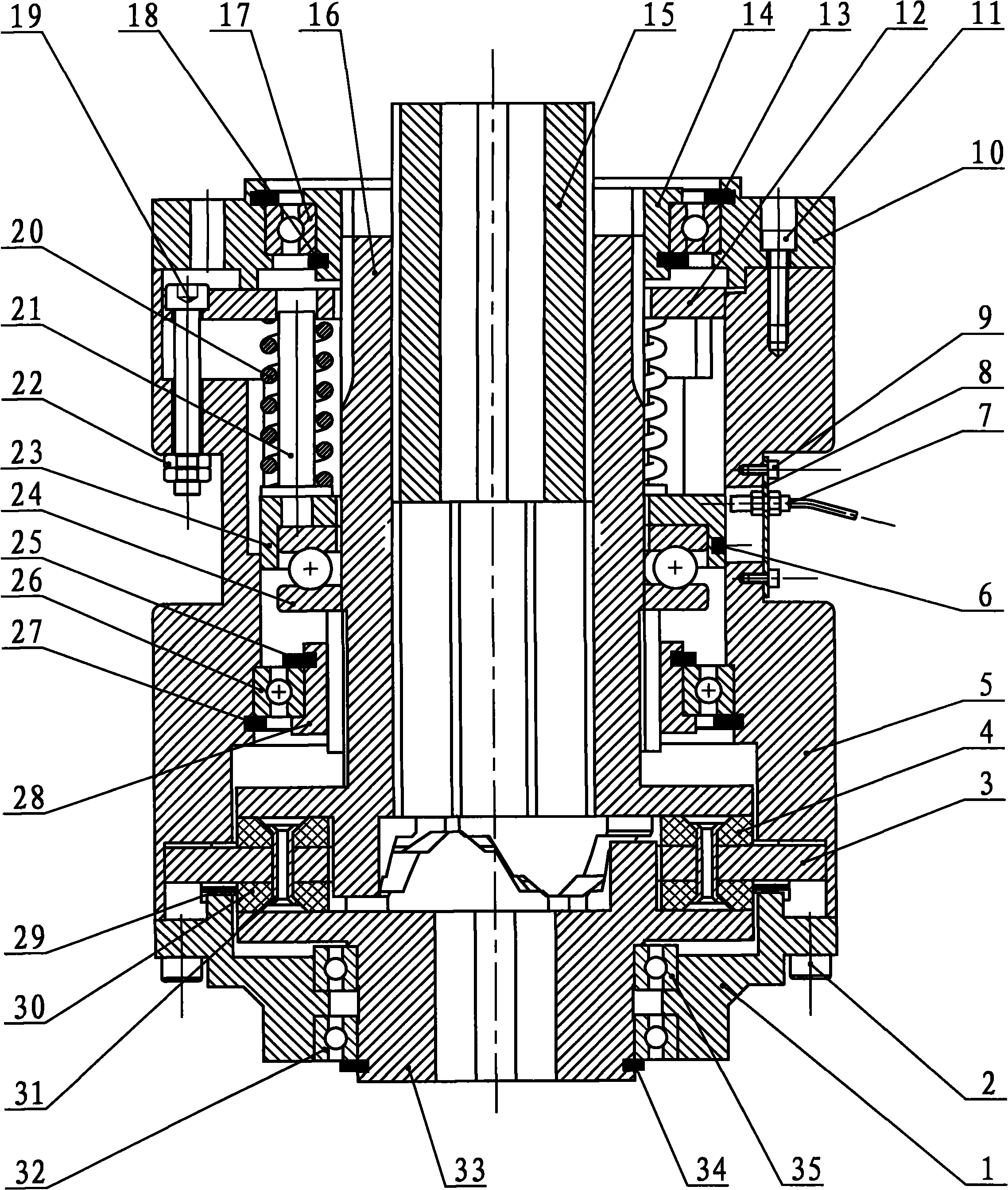

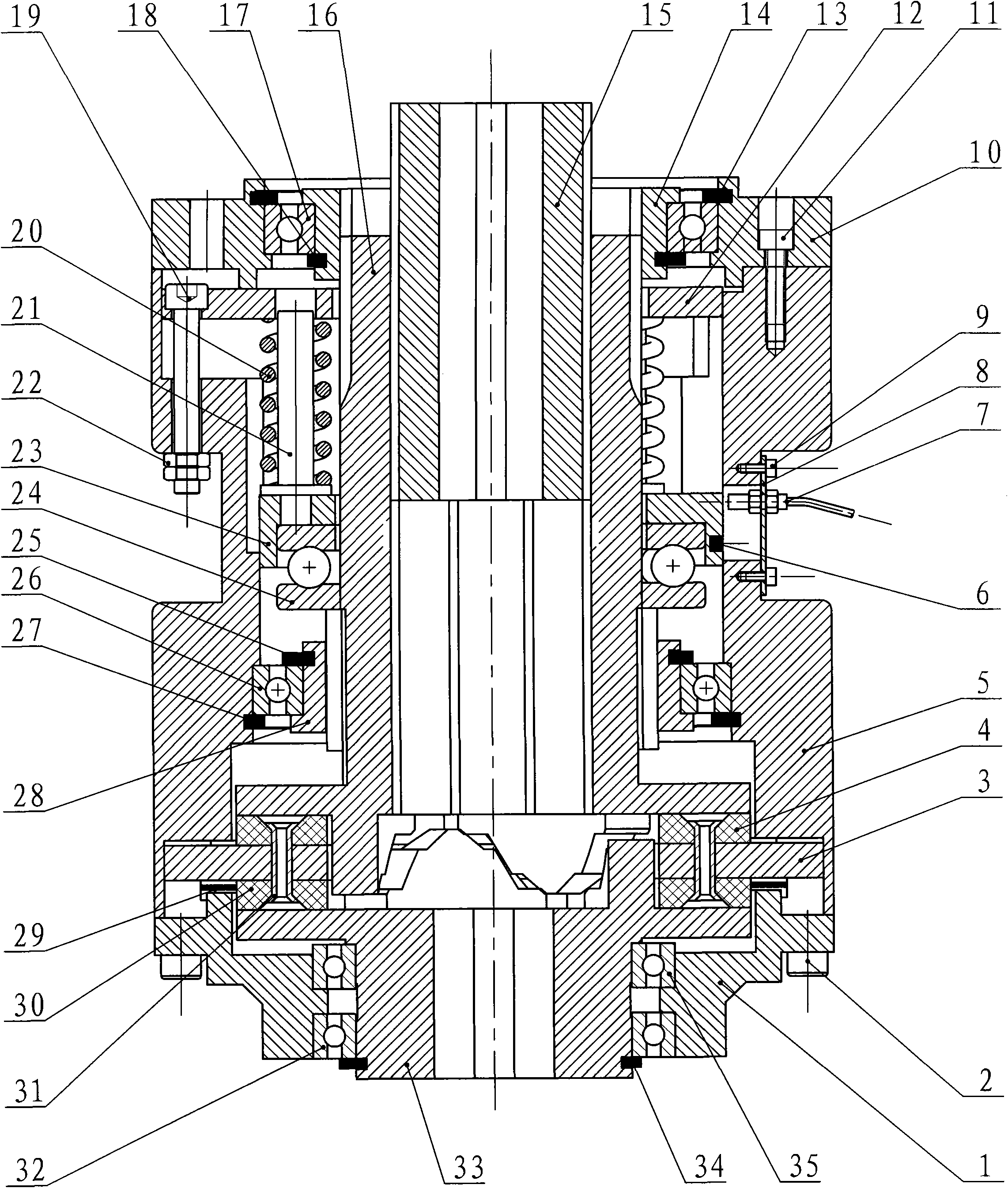

[0022] As shown in Figure 1 in the specification: the rolling bearing 35 and the rolling bearing 32 are connected together with the semi-driven coupling 33 in the form of interference fit, and the circlip 34 for the shaft is stuck in the ring of the shaft end of the semi-driven coupling 33. In the groove, the lower end cover 1 is fixed on the housing 5 with a plurality of hexagon socket head cap screws 2 , and the wave spring 29 is placed on the lower end cover 1 and stuck in the inner ring groove of the housing 5 .

[0023] As shown in Figure 1 in the specification, the friction plate 4 and the friction plate 30 are fixed on the friction plate support 3 by glue joint and riveting of four (or more) copper rivets 31, and the toothed friction plate support 3 is stuck on the shell 5 on several grooves at the lower end.

[0024] As shown in Figure 1 in the specification, the inner hole of the rolling bearing 26 and the outer circle of the lower positioning sleeve 28 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com