Valve and flow rate regulating device thereof

A technology of flow regulating device and adjusting bolt, which is applied in the direction of valve device, fluid pressure actuating device, valve operation/release device, etc. It can solve the problems of limited application range, difficult realization, complex structure, etc., and achieves convenient operation and easy Realization, strong wild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

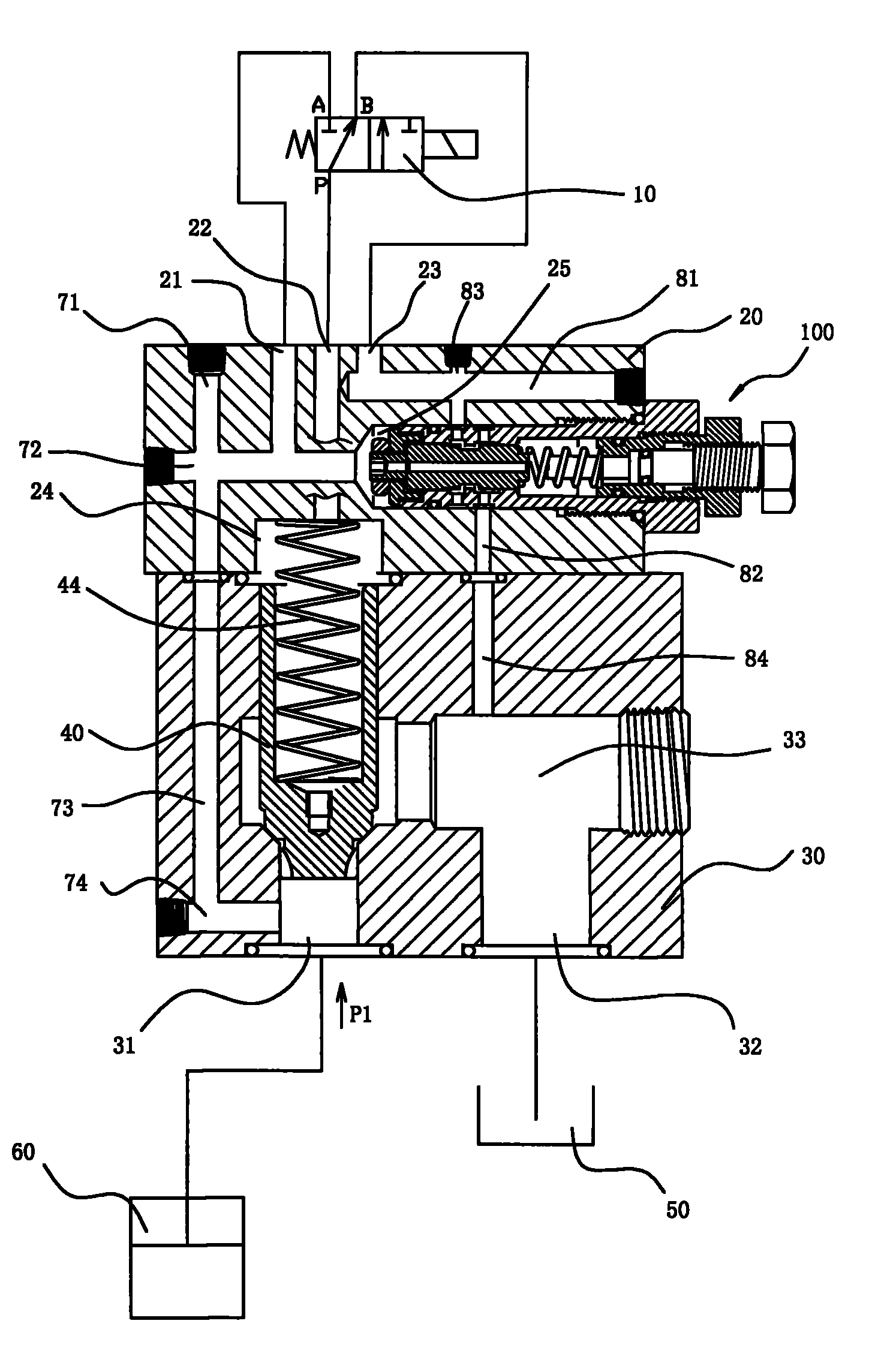

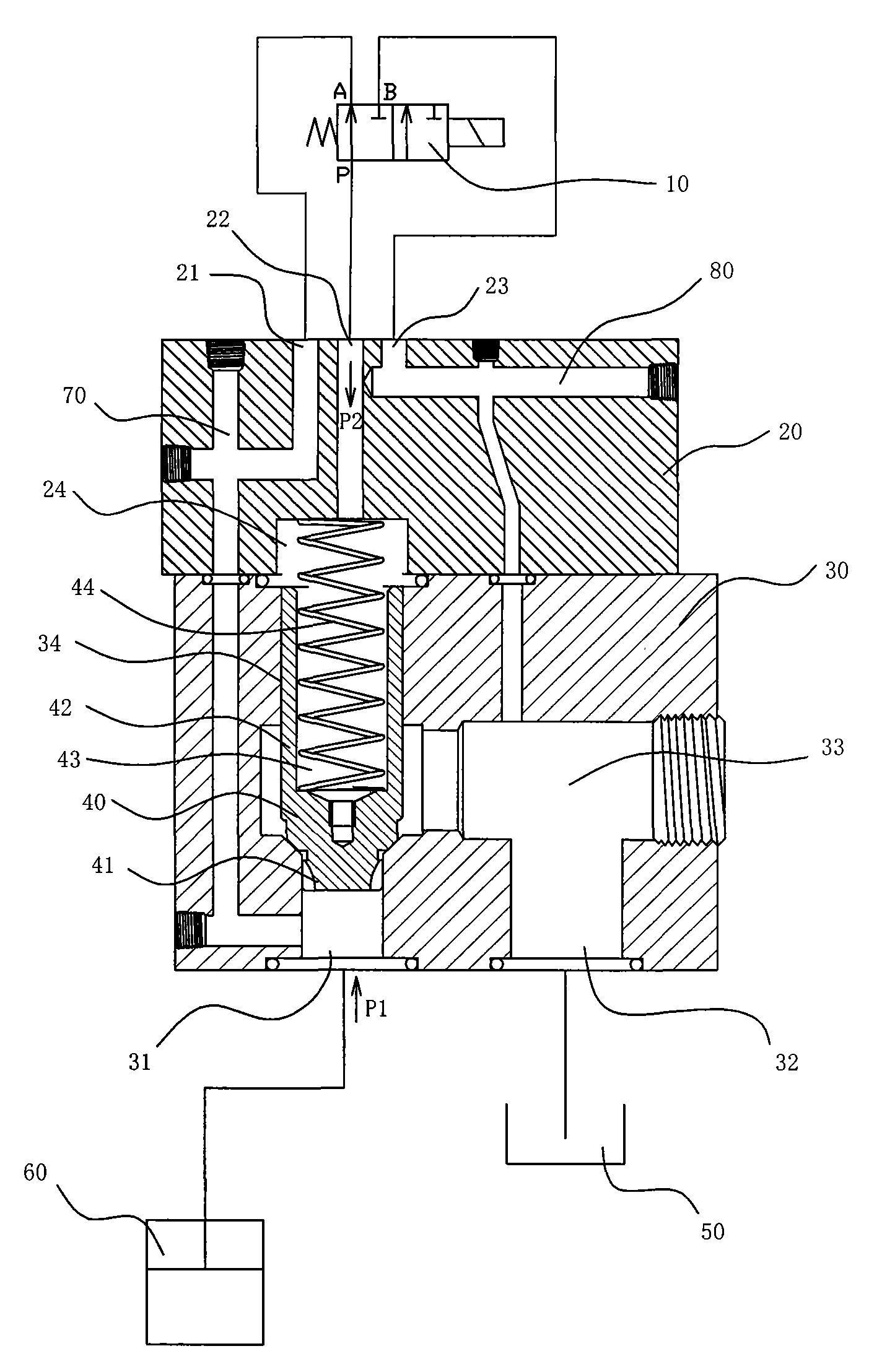

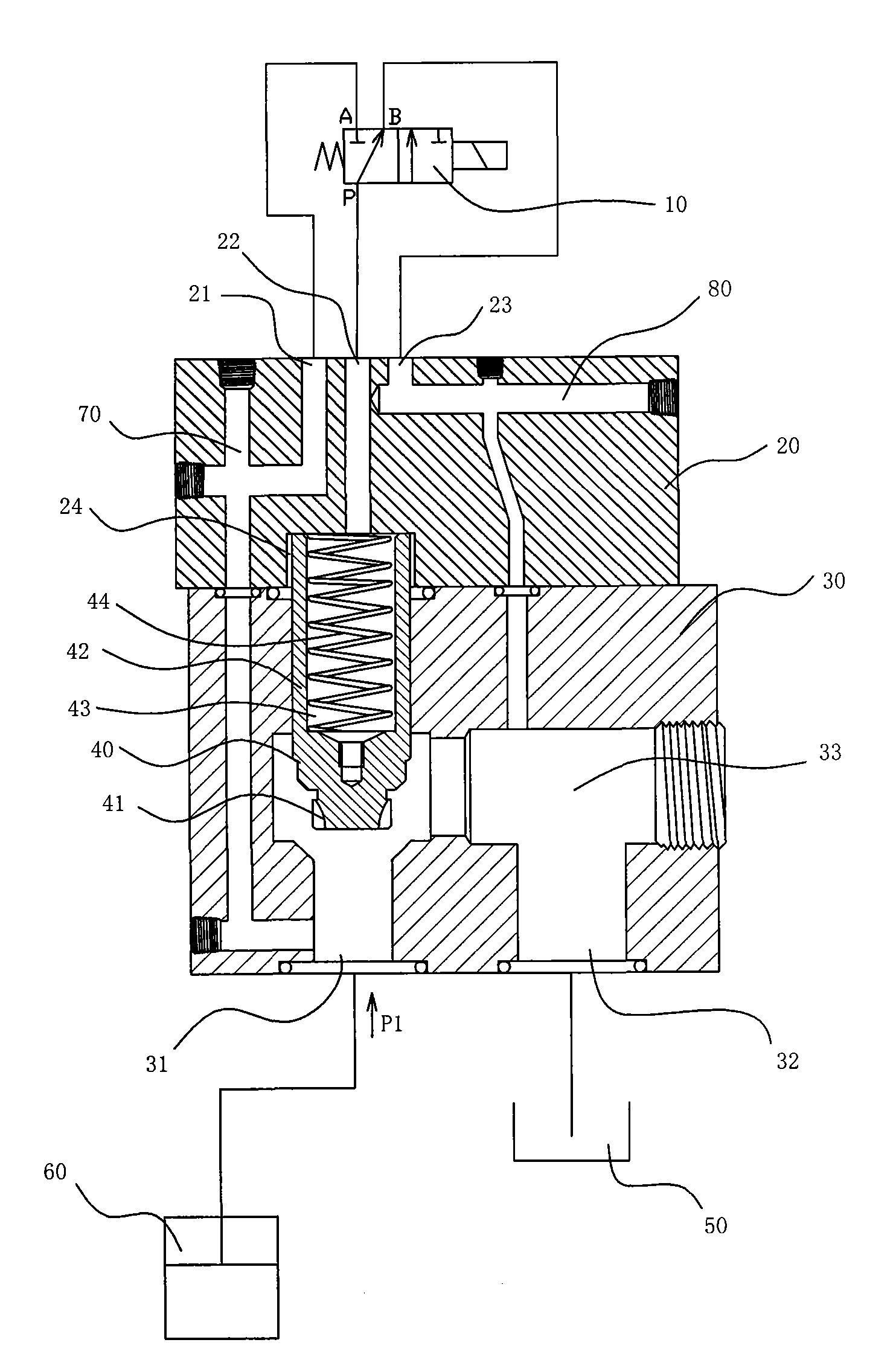

[0030] Fig. 3 and Fig. 4 are respectively a structural sectional view and an exploded view of a pressure relief valve according to an embodiment of the present invention. As shown in the figure, it can be seen that the present invention is a further improvement on the existing pressure relief valve shown in FIG. 1 , and thus has the same main structure as the existing pressure relief valve.

[0031]As shown in FIG. 3 and FIG. 4 , a pressure relief valve according to an embodiment of the present invention includes an upper valve body 20 , a lower valve body 30 , a valve core 40 and a flow adjustment device 100 , and the pressure relief valve is controlled by a solenoid valve 10 . Opening and closing. Specifically, as shown in FIG. 4 , the upper valve body 20 and the lower valve body 30 are locked into one body by a plurality of screws 26 . The lower end of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap