Pallet transfer equipment

A pallet conveying and pallet technology, used in conveyors, mechanical conveyors, railway systems with propulsion equipment, etc., can solve the problem that the installation space of processing equipment is limited between the return line and the transmission line, and there is no space saving and installation space. Restricted and other problems, to achieve the effect of easy and accurate vertical positioning, space saving, and ensuring the working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Hereinafter, one Embodiment of the tray conveyance facility of this invention is demonstrated based on drawing.

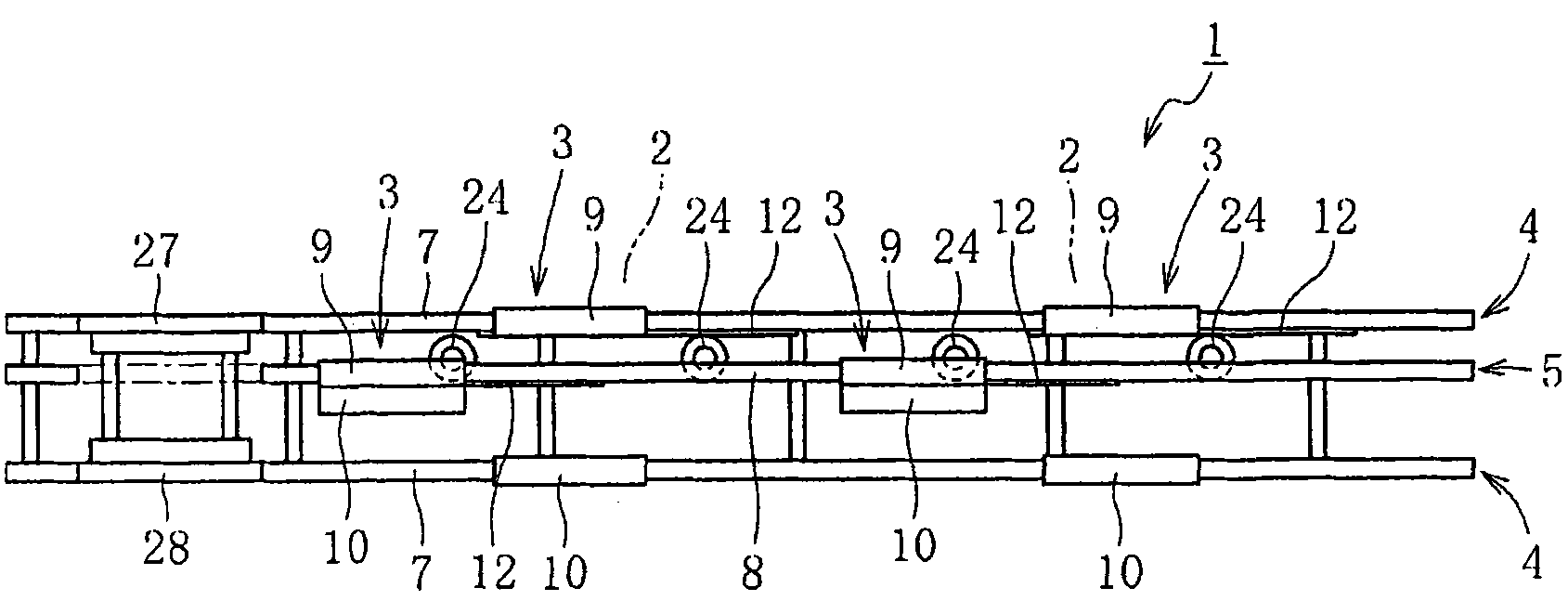

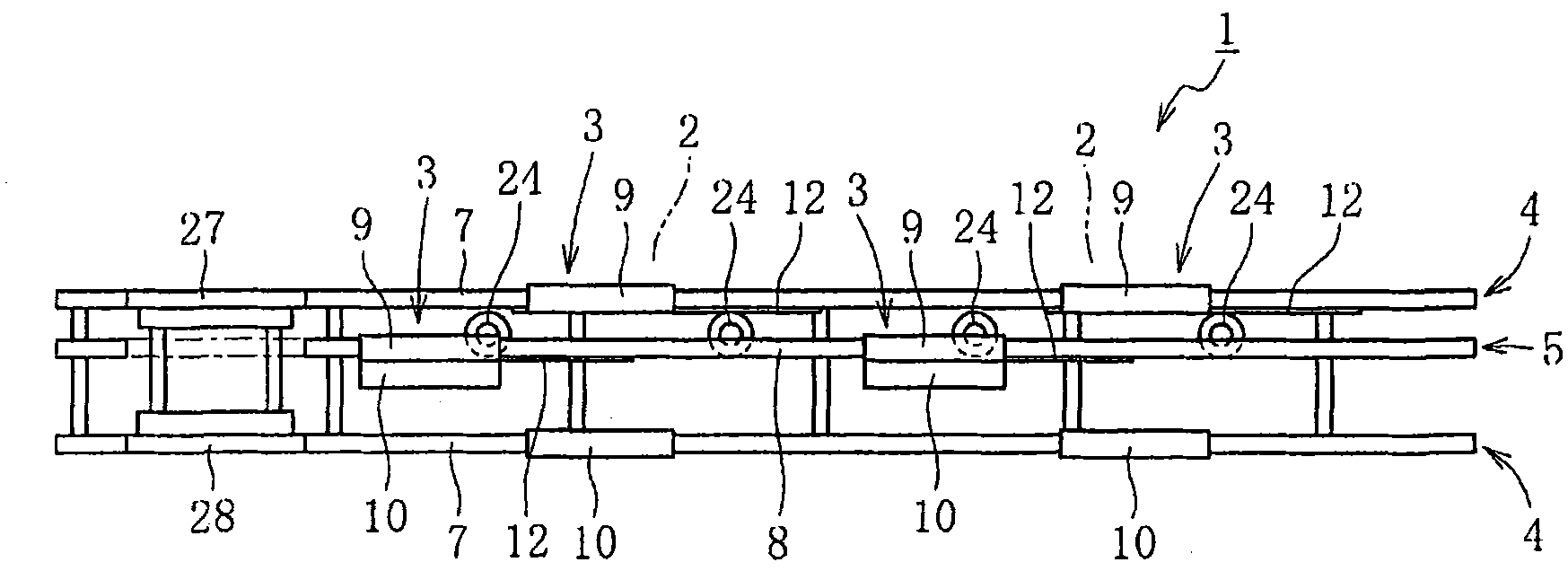

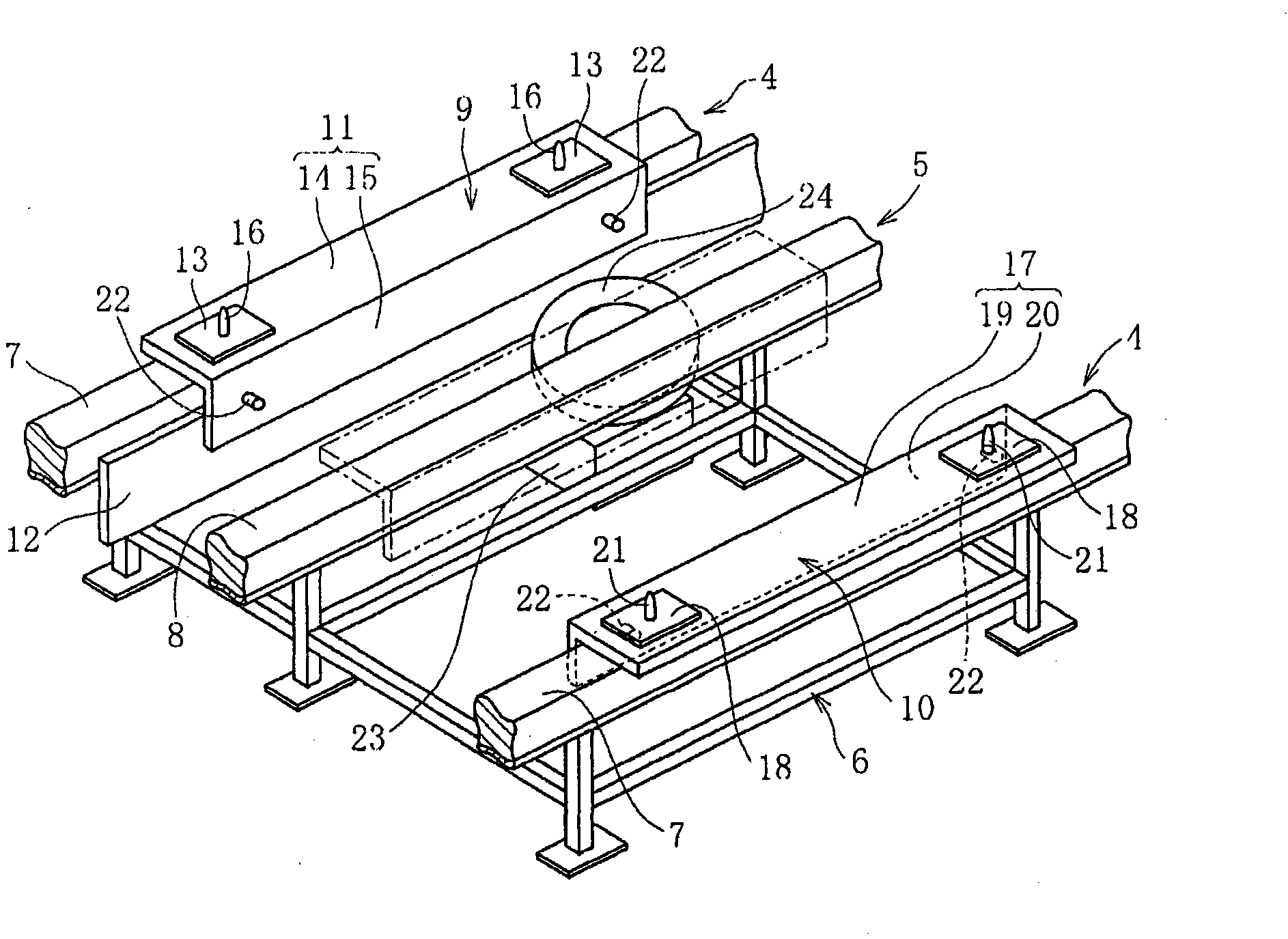

[0072] FIG. 1 is a plan view of a part of a tray conveyance facility according to one embodiment of the present invention. As shown in the figure, this conveying equipment 1 is a part incorporated into a line for conveying a vehicle body 2 as a workpiece, and has a conveying line 4 for conveying a pallet 3 on which a vehicle body 2 is placed (here, a workpiece conveying with pallets); a return line 5 which returns empty pallets 3 from the end of the transfer line 4 .

[0073] Here, the transmission lines 4 are arranged in two rows parallel to each other. In this embodiment, as shown in FIG. 2 , each transmission line 4 is constituted by a transmission rail 7 arranged on a frame 6 as a base. Furthermore, the loopback line 5 is arranged between two parallel transmission lines 4 , and is constituted by loopback rails 8 arranged on the frame 6 as a base, simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com