Tester for moisture regain rate of raw cotton

A moisture regain, measuring instrument technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of reducing the service life of instruments, leakage of electrodes, easy deformation and cracking, etc., to ensure the correctness of measurement and ensure normal safety. The effect of using and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

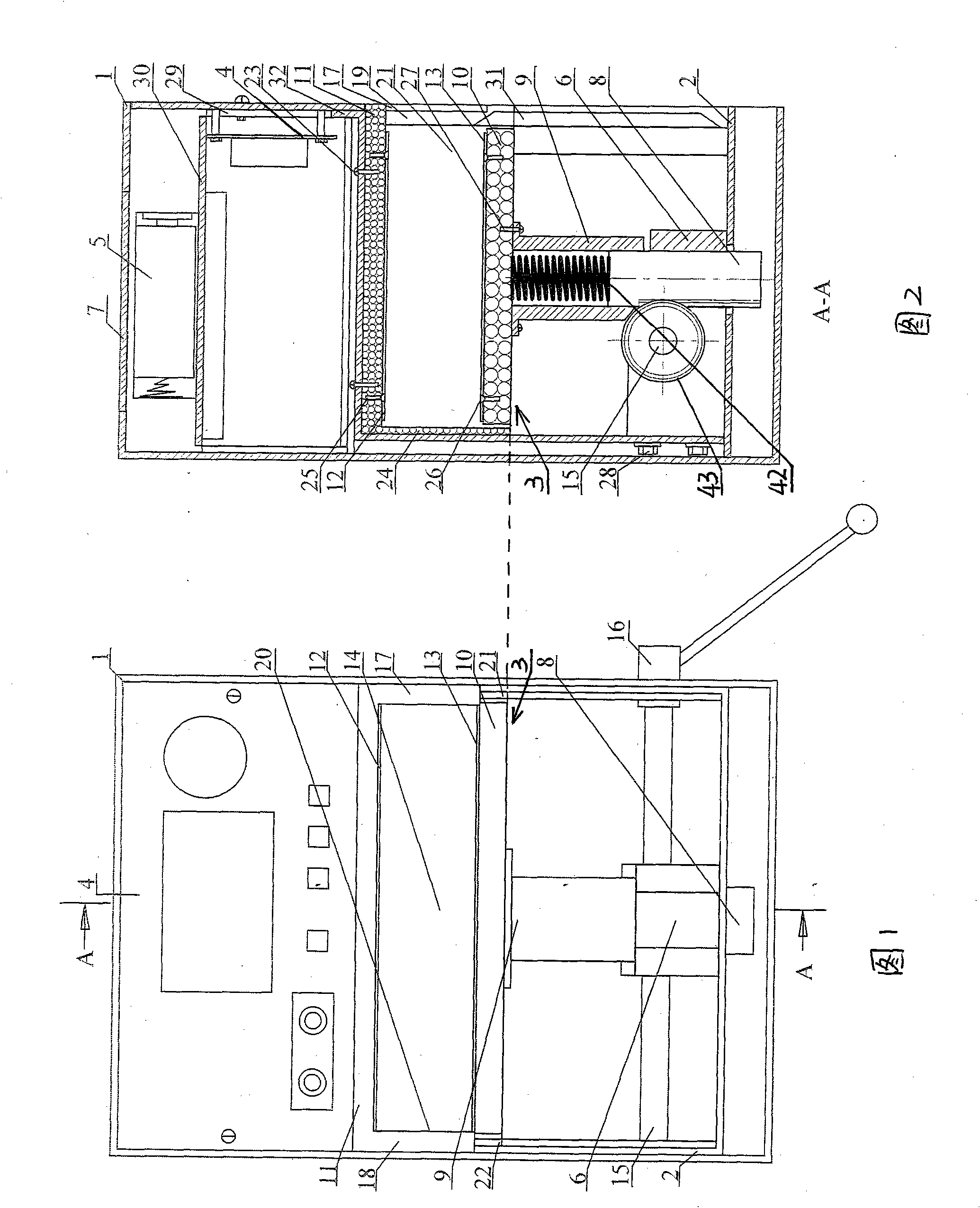

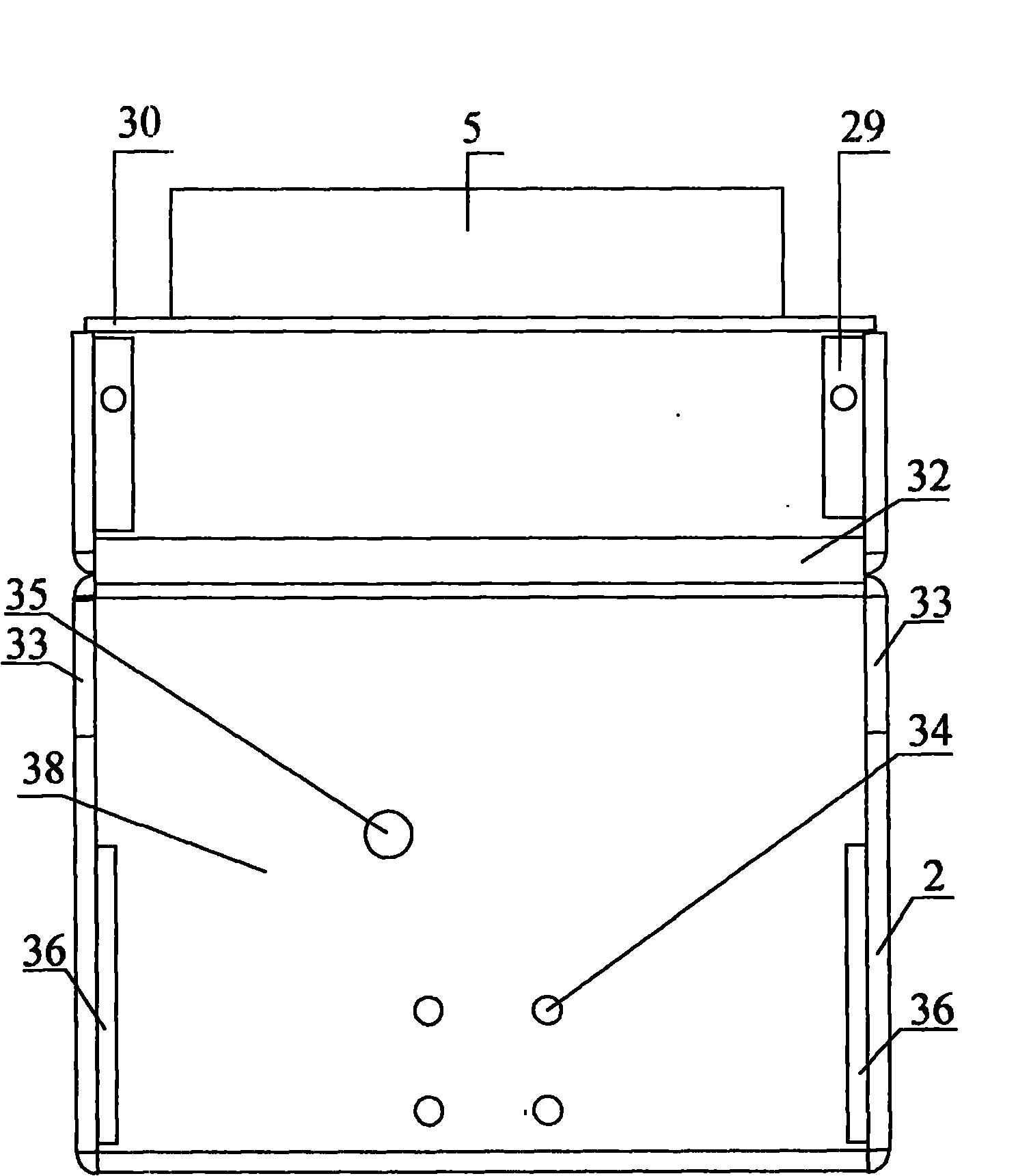

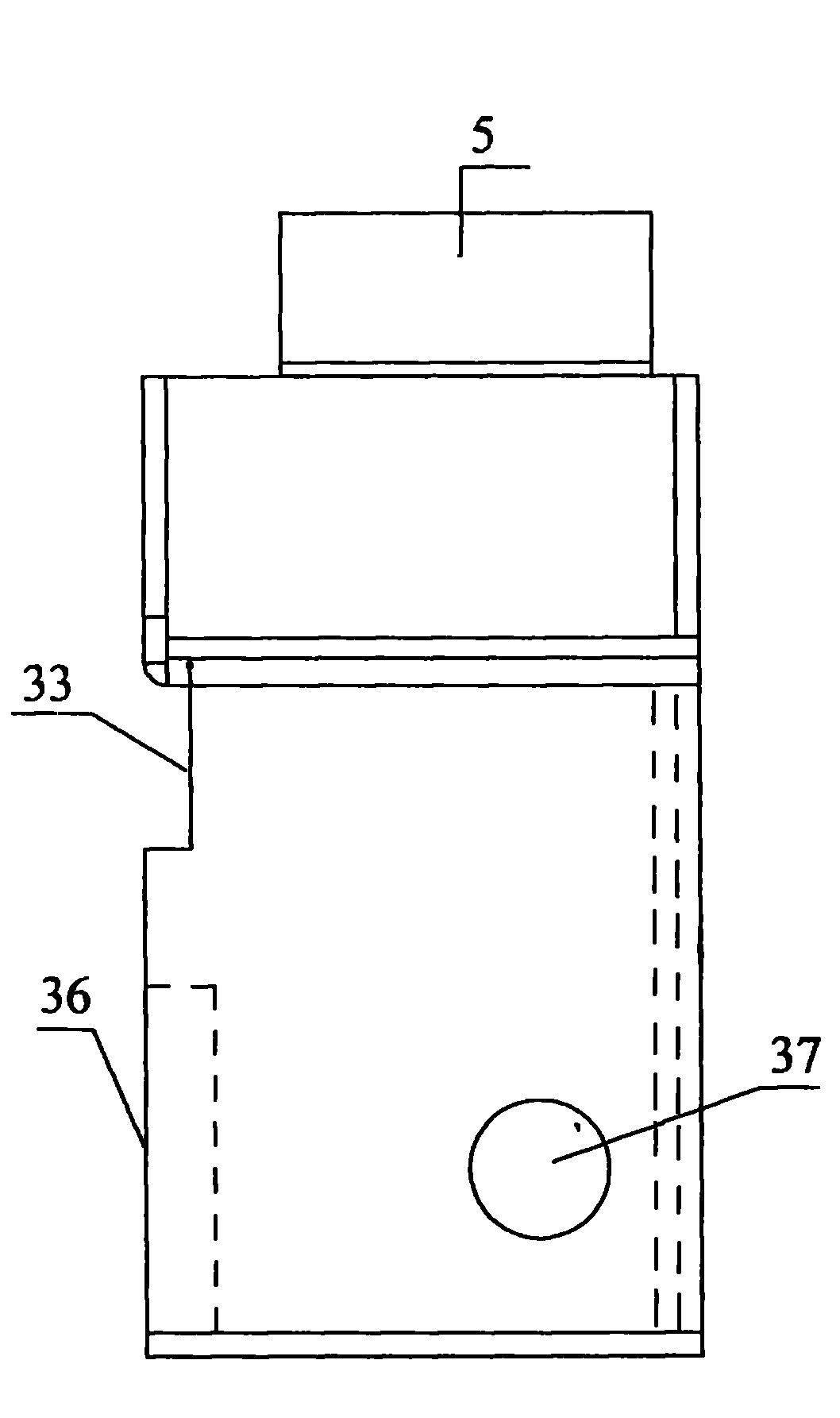

[0020] The structure of the present invention will be further explained below in conjunction with the drawings.

[0021] See Figure 1-Figure 6 As shown, a raw cotton moisture regain tester includes a housing 1 with an inner cavity. The housing 1 can be made of a metal material, such as aluminum alloy. The tester adopts a metal housing, which can improve the appearance of the tester and enhance its robustness. . A metal frame 2 is provided in the housing 1, and the frame 2 is made of metal materials, such as steel plates. In order to improve production efficiency, the metal frame 2 can be responsible for the installation of various parts in the tester. The metal frame 2 is equipped with the organic core assembly 4, the battery rack assembly 5, the test cotton cavity 3, and the battery rack assembly 5 The battery can be a dry battery, or a rechargeable battery charged by direct current or alternating current, such as a lithium battery. The test cotton cavity 3 includes a fixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com