Well digging process of mining vertical shaft by adopting one-drilling well completion and well drilling method

A wellbore and shaft technology, which is applied in the direction of sinking, wellbore lining, shaft equipment, etc., can solve the problems of long auxiliary working time, slow well completion speed, large equipment occupation, etc., so as to reduce the area of storage site, reduce the amount of mud discharge, The effect of increasing the well-forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

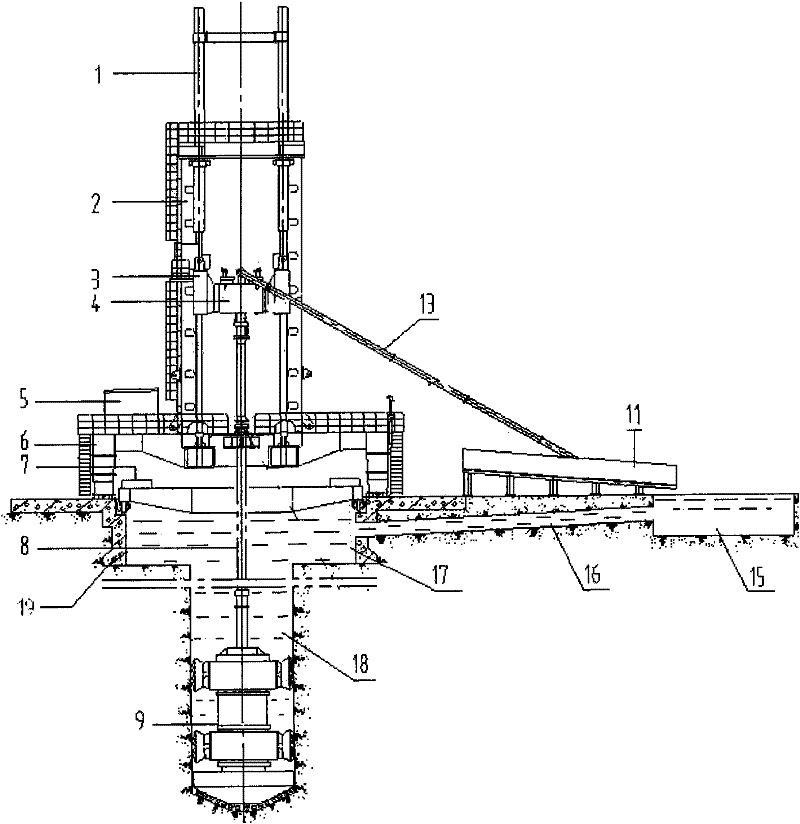

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] Depend on Figure 1 to Figure 2 Shown, this mine vertical shaft wellbore one-drilling well drilling method sinking process mainly comprises the following steps:

[0017] ① Well bore drilling, ② Well wall prefabrication, ③ Sinking well wall, ④ Backfilling;

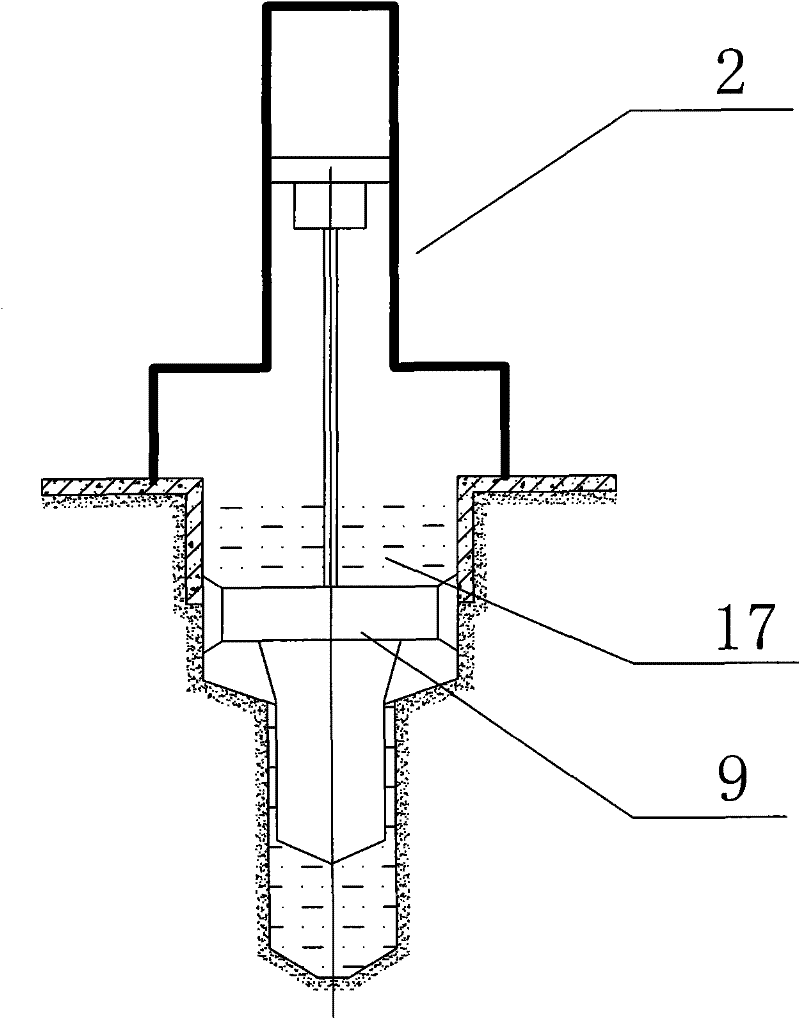

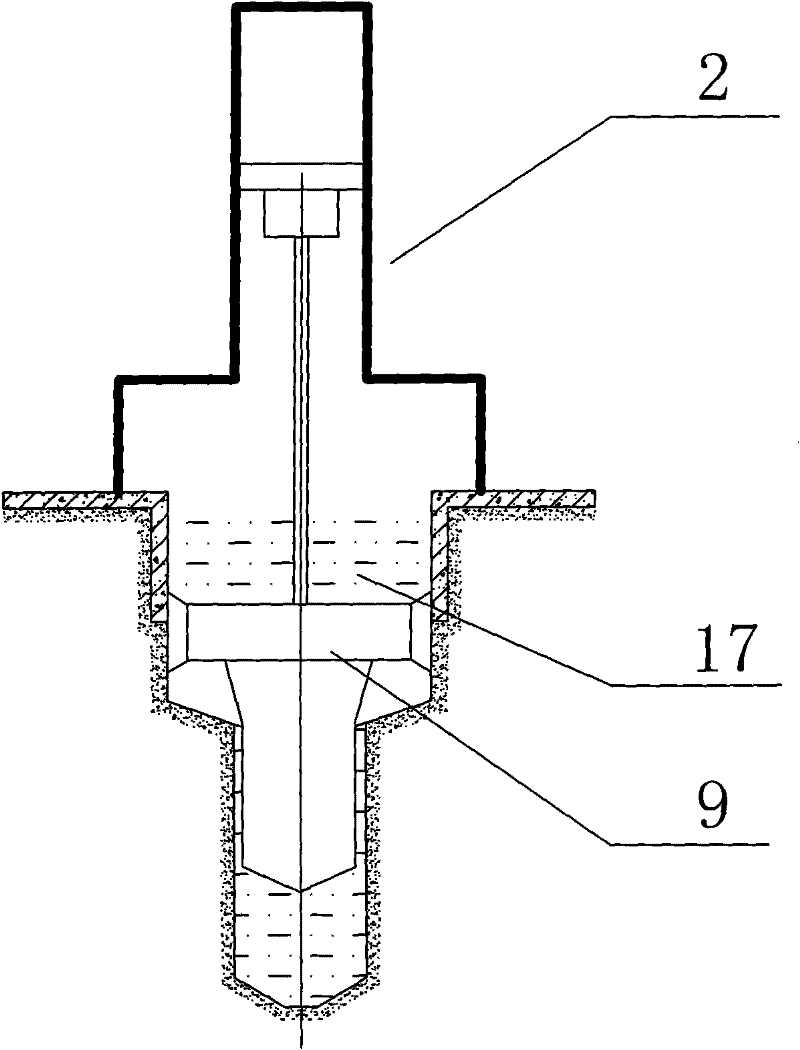

[0018] Firstly, ① wellbore drilling: the drilling adopts the form of a leading hole and a final hole, such as figure 1 As shown in the figure, 2 is the drilling frame, 17 is the mud, and 9 is the advanced hole final hole drill bit; the vertical shaft drilling machine is lifted by the power head type hydraulic cylinder, which is developed by Luoyang Mining Machinery Design and Research Institute and China Coal Special Drilling Co., Ltd. Jointly designed and manufactured, the model is AD130-1000 drilling rig; the drilling tool can choose spherical tooth hob or wedge tooth hob according to the geological conditions...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap