Valve timing control apparatus

A valve timing control, air technology, applied in valve devices, engine components, machines/engines, etc., to improve restart capability and reduce operating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

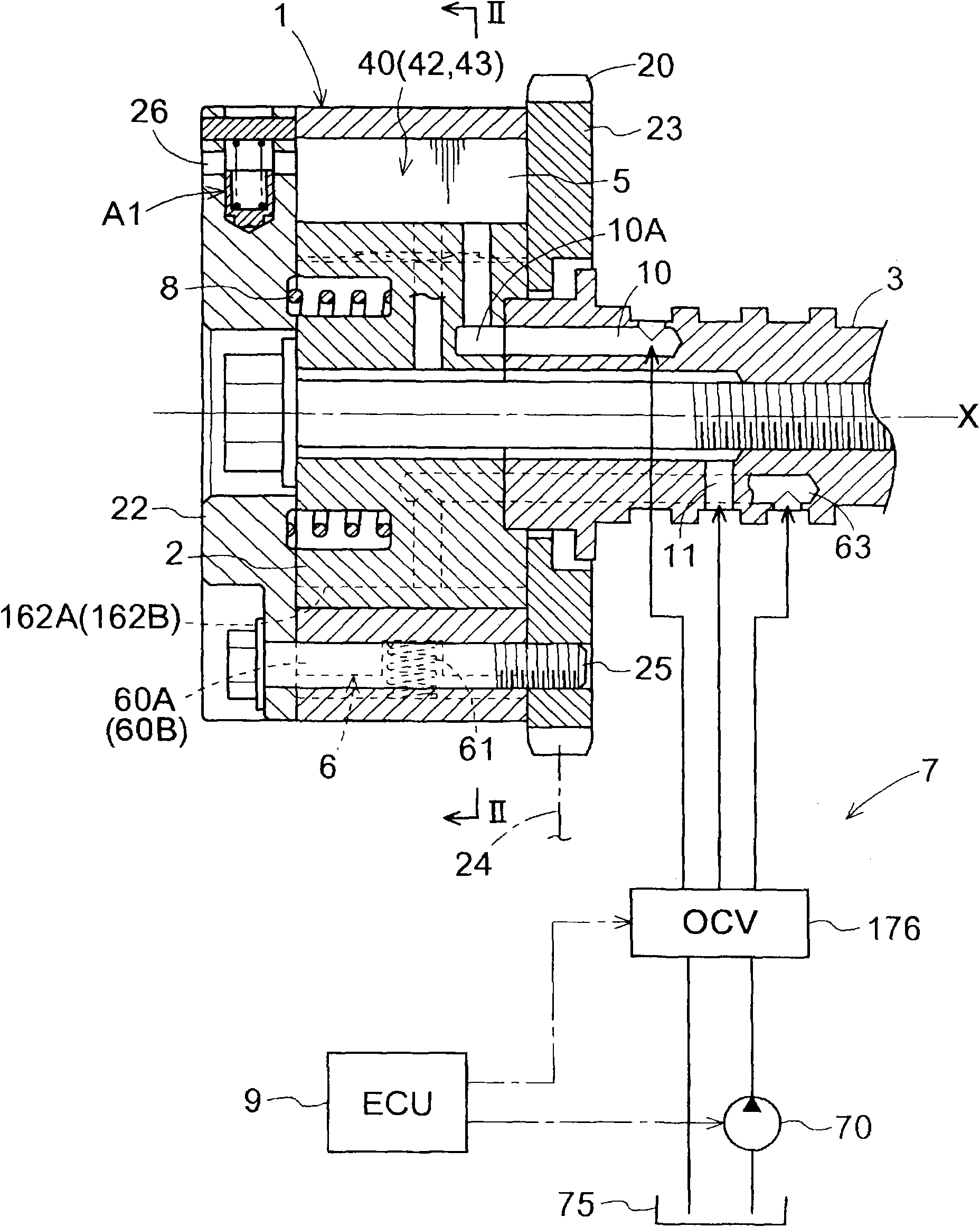

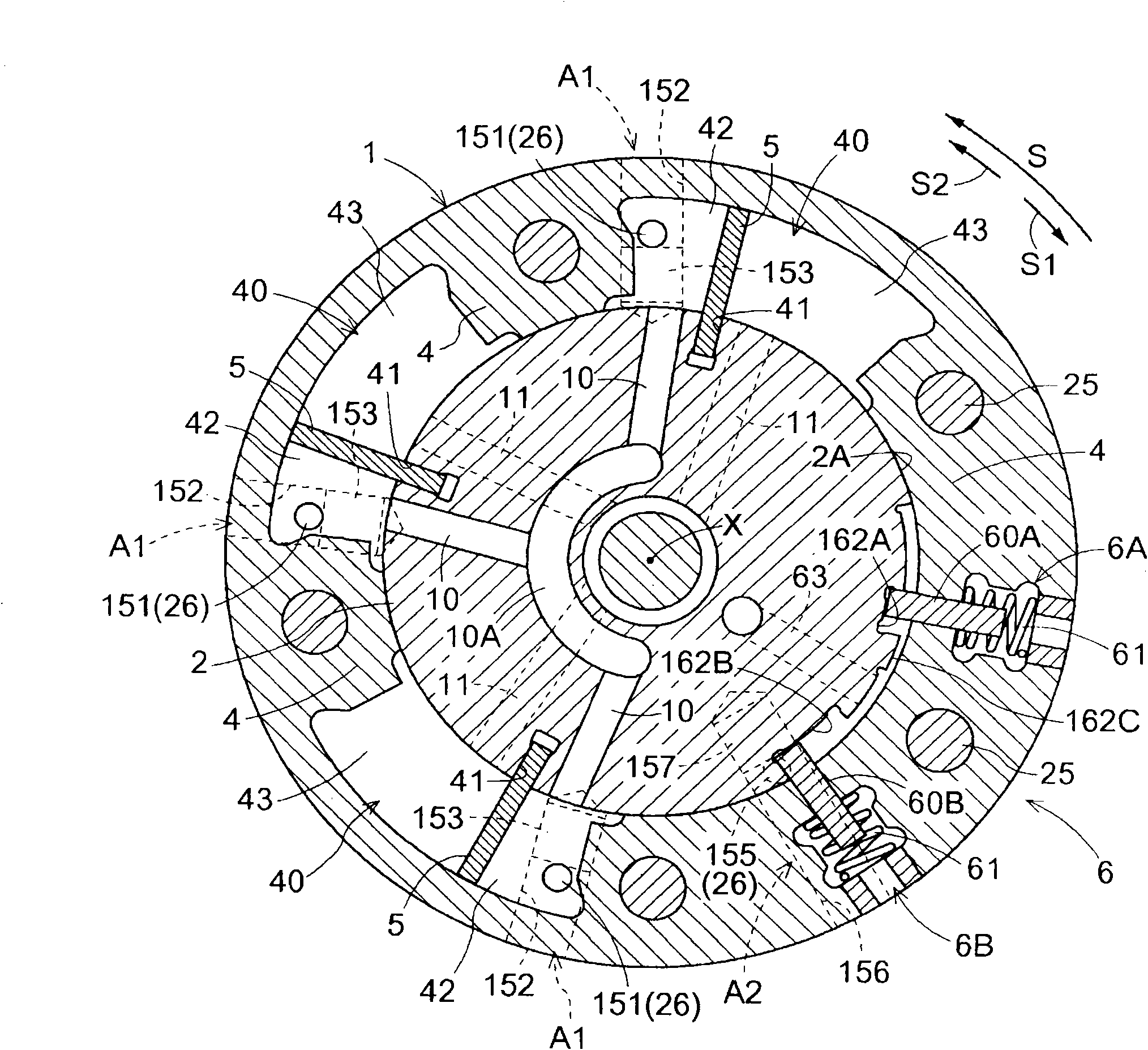

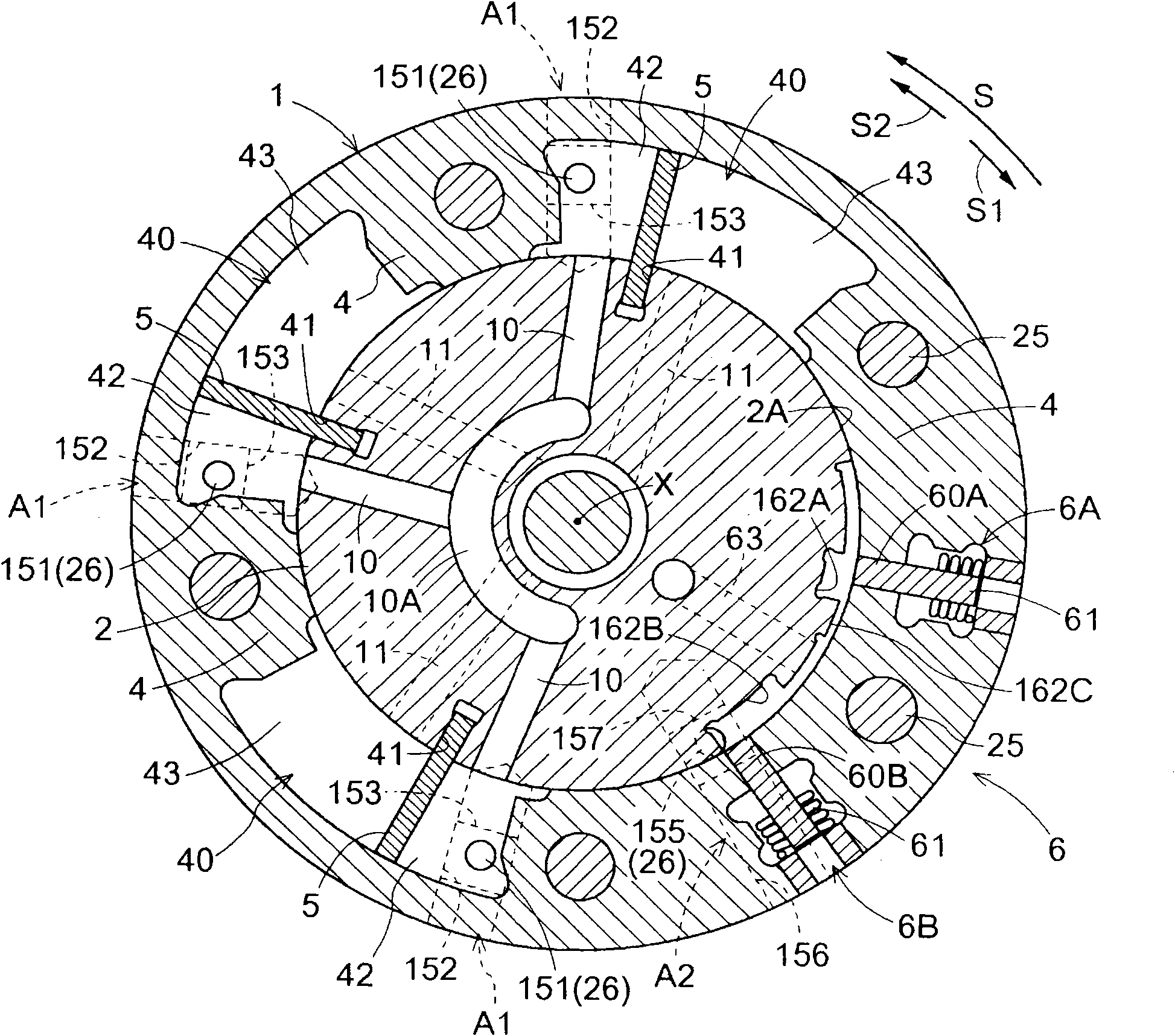

[0059] Below, according to the attached Figure 1 to Figure 9 , explains a first embodiment in which the valve timing control device is fitted at an intake valve of a vehicle engine. Figure 2 to Figure 5 A sectional view of the valve timing control device viewed from the rear plate 23 to the front plate 22 along the axial direction of the valve timing control device is shown.

[0060] [the whole frame]

[0061] Such as figure 1 and figure 2 As shown, the valve timing control apparatus according to the first embodiment includes an outer rotor 1 as a driving-side rotating member, and an inner rotor 2 as a driven-side rotating member. The outer rotor 1 rotates synchronously with the crankshaft of the engine (internal combustion engine). The inner rotor 2 is arranged coaxially with the camshaft 3 so that it can rotate synchronously with the camshaft 3 . The camshaft 3 controls the opening and closing operations of intake valves or exhaust valves provided at the combustion c...

no. 2 example

[0112] Refer to the accompanying drawings below Figure 10 to Figure 16 , to illustrate the second embodiment of the valve timing control device. The structural description of the valve timing control device similar to the first embodiment is omitted here, and more specifically, the description of the overall structure of the valve timing control device, the hydraulic chamber, and the torsion spring are omitted. Therefore, only the differences between the first embodiment and the second embodiment will be described below. In addition, the components in the second embodiment that are substantially the same as those in the first embodiment are assigned the same reference numerals and symbols as in the first embodiment. Figure 10 is a sectional view illustrating the overall structure of the valve timing control device according to the second embodiment as viewed in a direction orthogonal to the relative rotational axis X. FIG. Figure 11 It is a diagram illustrating a combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com