Integrated corrosion resisting impeller

An anti-corrosion, integrated technology, used in non-variable-capacity pumps, liquid fuel engines, and components of pumping devices for elastic fluids, etc., can solve problems such as screw fall off, complex processing technology, and large impeller resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

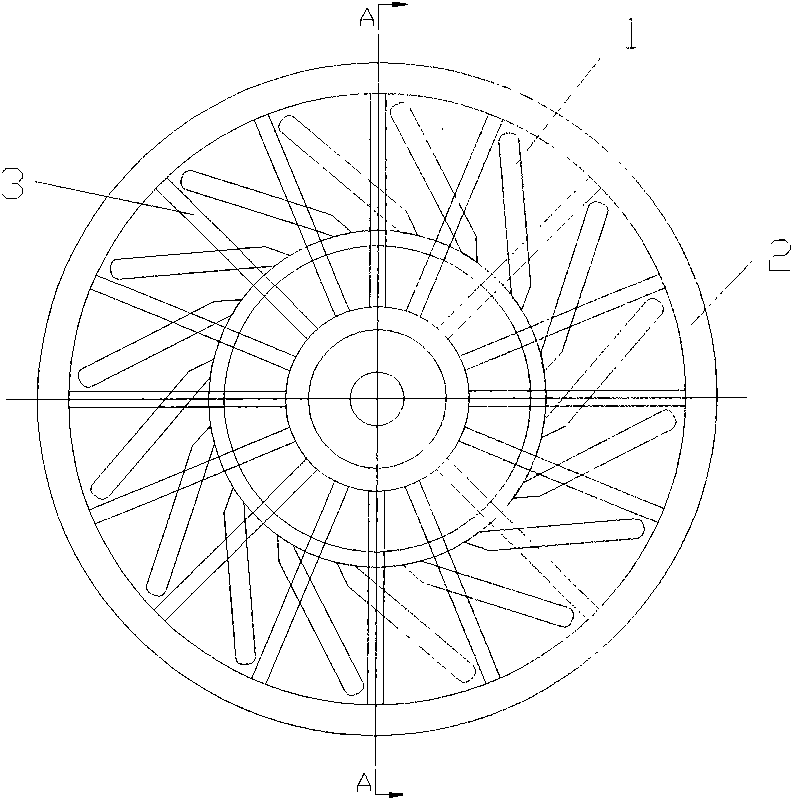

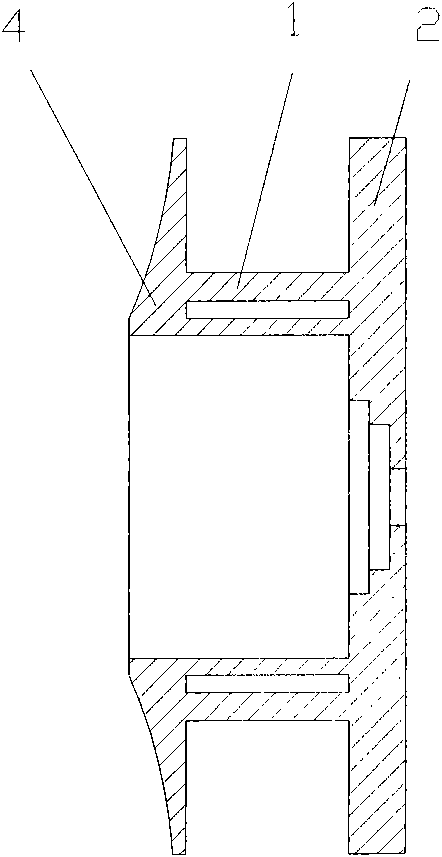

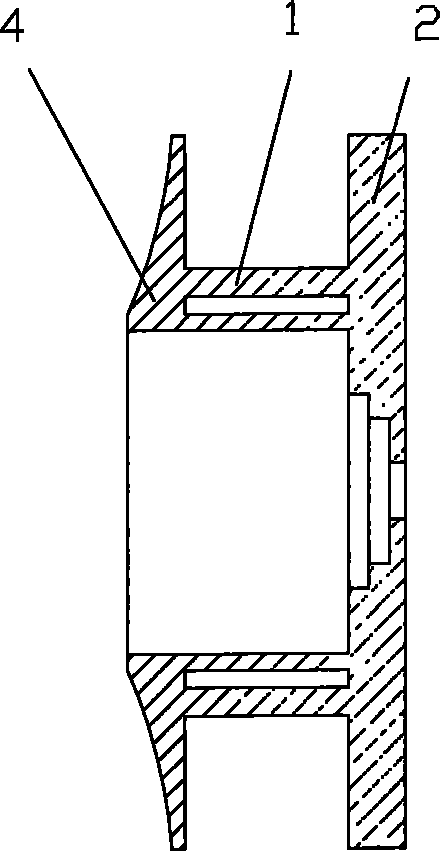

[0010] figure 1 shows a perspective view of the impeller in the present invention, figure 2 yes figure 1 Section A-A of the impeller shown.

[0011] Such as Figure 1-2 As shown, the impeller includes an inner disc 2, an outer disc 4 and a blade 1; the bottom of the inner disc 2 has a rib 3, and the outer disc 4 has a wind tunnel; the blade 1 is arranged on the Between the inner disc 2 and the outer disc 4.

[0012] The inner disc 2, the outer disc 4 and the blade 1 are integrally formed by hot pressing through a mold.

[0013] Preferably, said impeller is made of plastic.

[0014] Since the impeller is integrally formed by hot pressing, it avoids the disadvantages of complex processing technology, time-consuming, laborious, high resistance and poor efficiency when forming by screw assembly, bonding, riveting, welding, etc. , At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com