Fastening pattern cutting collecting pipe of parallel flow condenser and processing technique thereof

A processing technology and condenser technology, which is applied in the field of fastening sample cutting header and its processing technology, can solve the problems of high technical requirements, high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

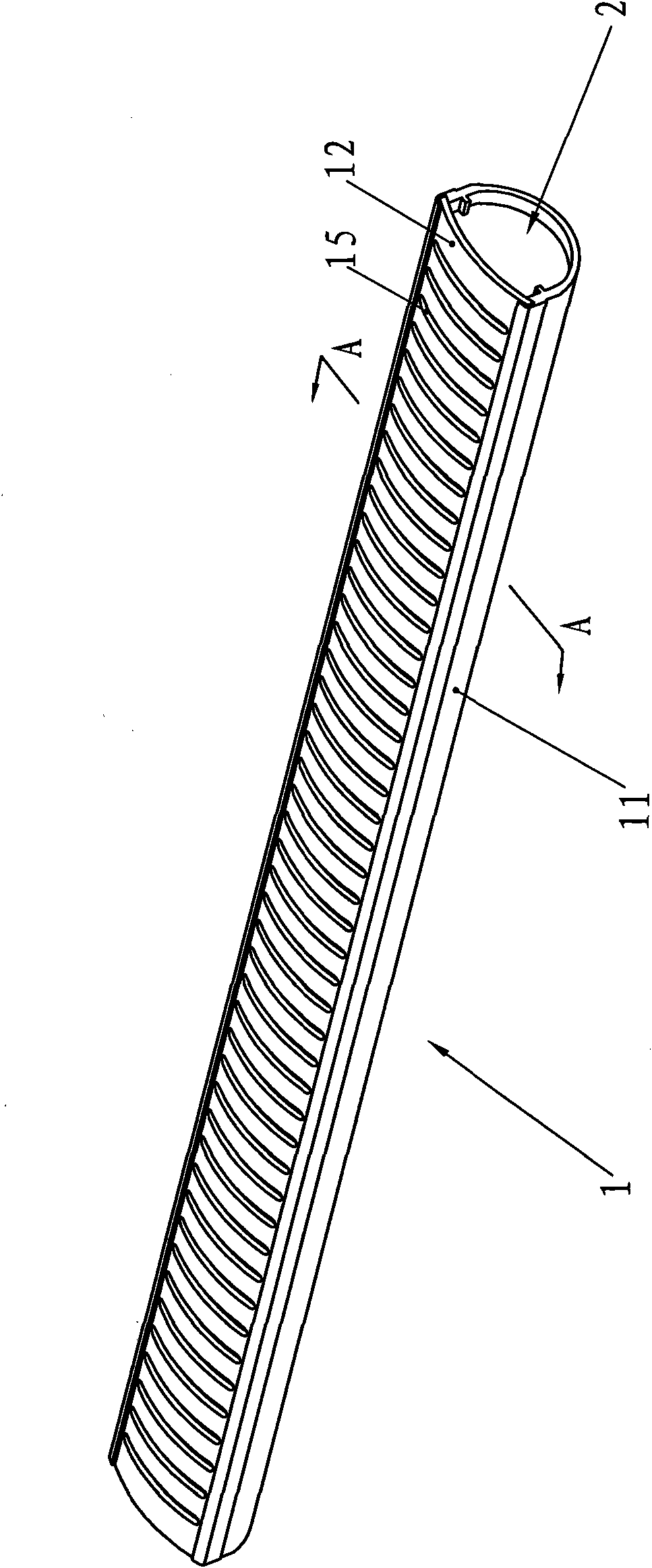

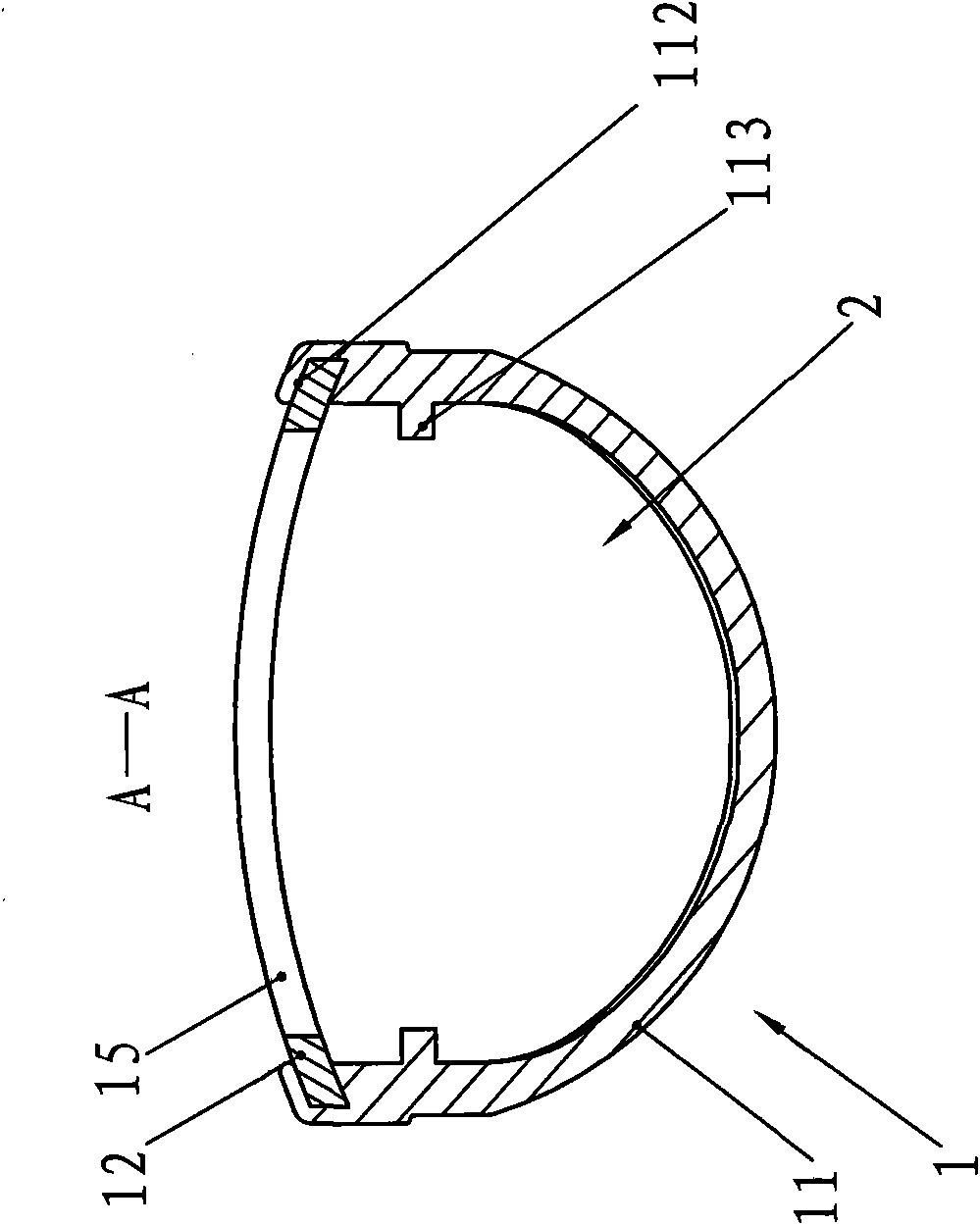

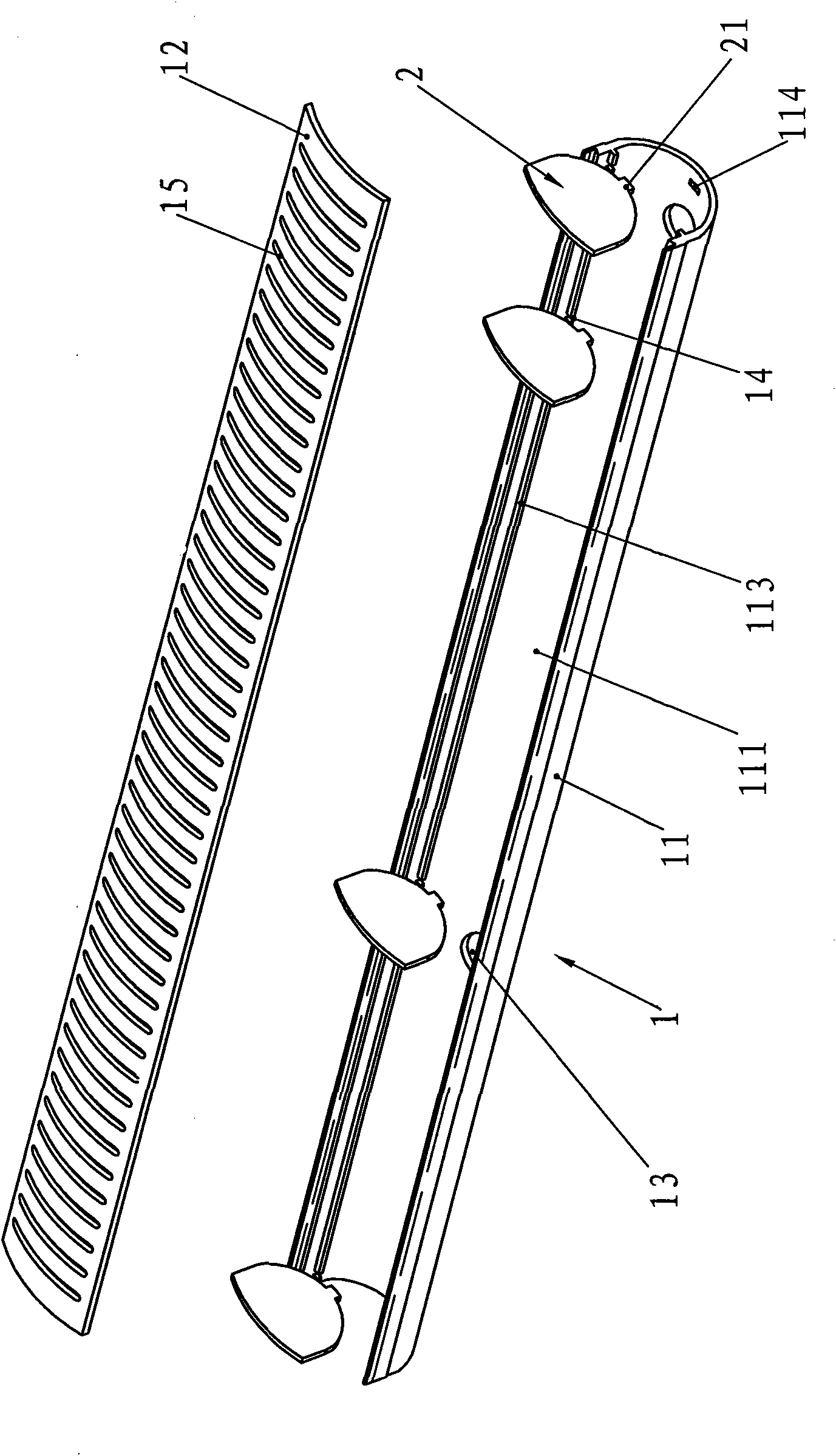

[0024] Such as figure 1 , figure 2 , image 3 The snap-fit cutting header of a flat-flow condenser shown includes a tube body 1, and a harmonica tube installation hole 15 for inserting a harmonica tube is uniformly opened on the tube body 1, and inside the tube body 1, there are There are refrigerant liquid inlet and outlet interfaces and partitions 2 that separate the refrigerant liquid inlet interface to form the internal flow channel of the pipe body. The pipe body 1 includes a fastening pipe 11 and a welding plate that is fastened and welded with the fastening pipe 11 12. The internal space after the fastening tube 11 and the welding plate 12 are combined is a flow channel, and the refrigerant liquid inlet and outlet ports 13 are evenly distributed on the fastening pipe 11, and the buckling pipe 11 is located between the refrigerant liquid inlet and outlet ports 13 There is a slot 14 for the insertion of the spacer 2, and the spacer 2 is inserted into the flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com