Glue and acid pouring machine for accumulators

A storage battery and glue filling technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of unguaranteed consistency of glue quantity and difference of glue quantity, etc., so as to increase the number of charging and discharging cycles and reduce internal resistance , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

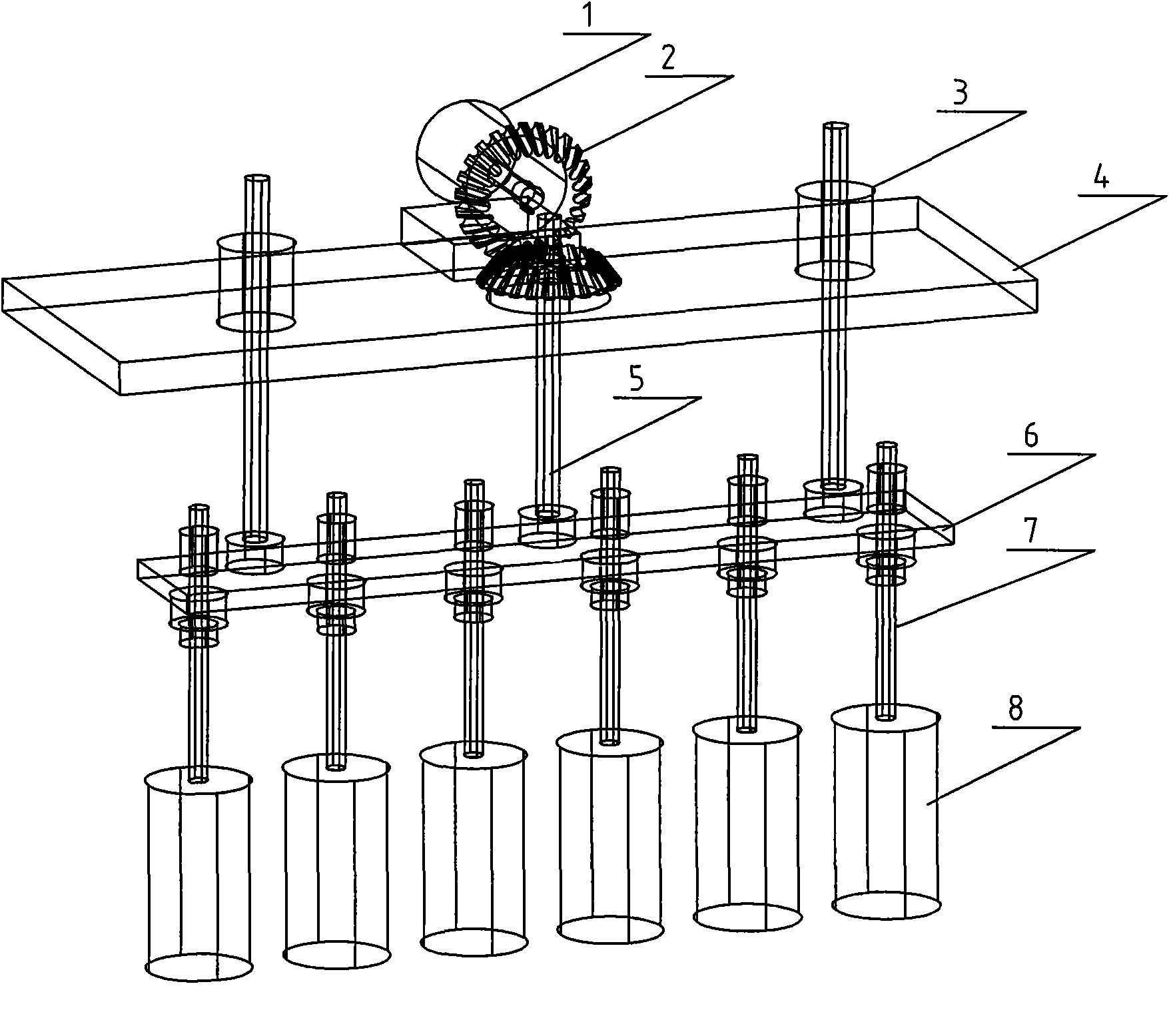

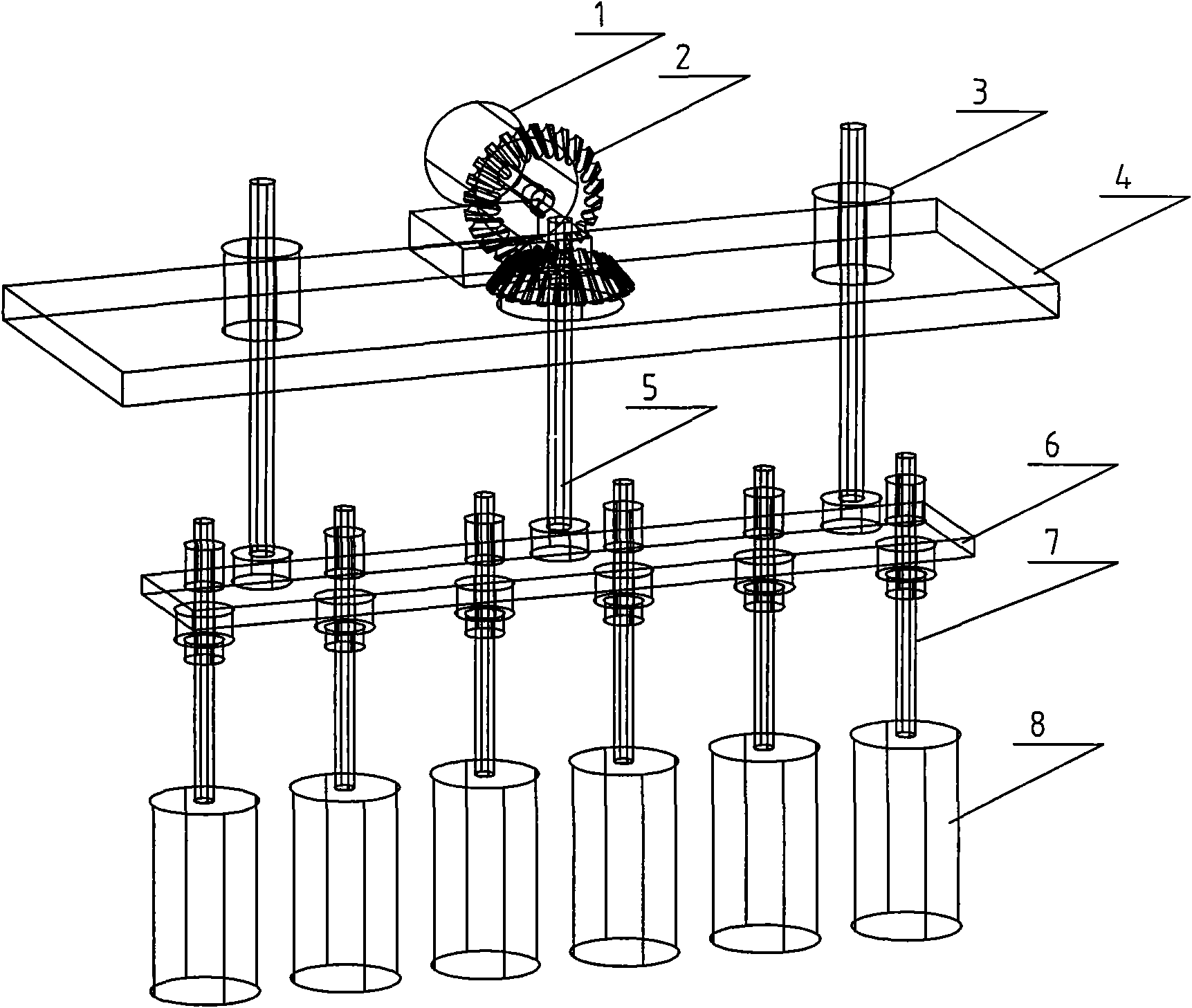

[0008] The present invention comprises a motor 1 controlled by a microcomputer, the output end of the motor 1 is connected to a lifting shaft 5 connected with a movable plate 6, and the movable plate 6 is provided with some hollow volume-adjusting shafts 7, and the bottom of each volume-adjusting shaft 7 is provided with There is a quantitative hammer 8 cooperating with the adjusting shaft 7, the adjusting shaft 7 extends into the cavity of the quantitative hammer 8, and the quantitative hammer 8 is fixed on the frame.

[0009] The working process of the present invention is: first pour glue and acid into the quantitative hammer 8 through the adjusting shaft 7, start the DC motor 1 fixed on the fixed frame 4, and the DC motor 1 drives the lifting shaft 5 to move up and down through the transmission of the gear 2, and the lifting shaft 5 moves up and down. The lower part of the shaft 5 is connected with a movable plate 6, and the connection between the fixed frame 4 and the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com