Accumulator plate

A battery and plate technology, applied in lead-acid battery electrodes, active material electrodes, electrode carriers/current collectors, etc., can solve the problem that the active material on the plate is easy to fall off, reduce the battery capacity and cycle life, and the plate is bent, etc. The problem is to overcome the easy shedding of active substances, increase active substances, and prevent shedding.

Inactive Publication Date: 2010-09-01

JIANGSU OLITER ENERGY TECH

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Paste-coated battery plates are currently used as battery plates. Single-side paste technology is generally used, and there are few surface active substances. It is easy to cause the plate to bend during formation, and the active material on the cured plate is easy to fall off. , which reduce the capacity and cycle life of the battery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

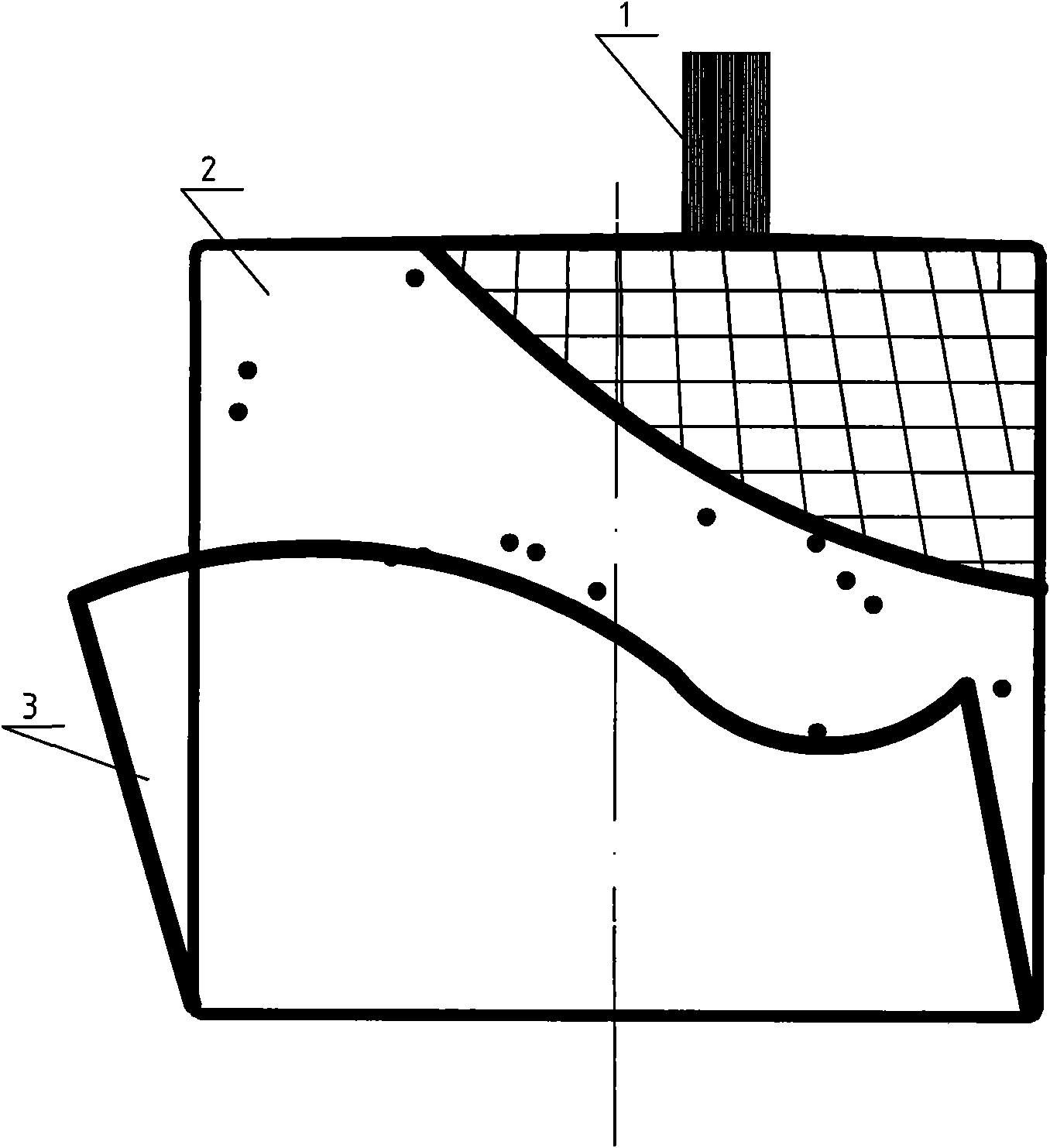

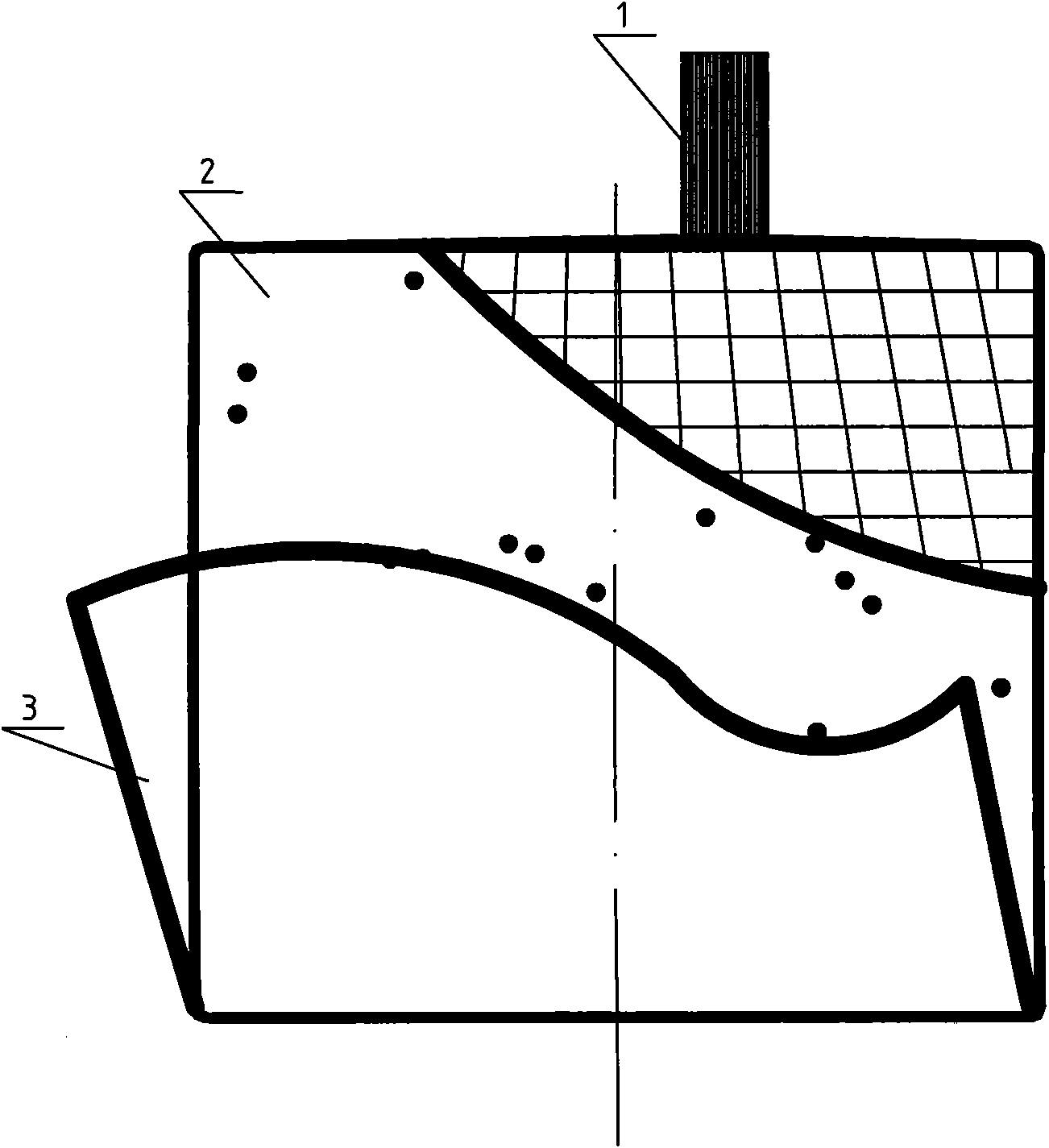

[0008] The invention includes a storage battery grid 1, both sides of the storage battery grid 1 are coated with an active material layer 2, and an electrode film 3 is arranged outside the active material layer 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an accumulator plate, which comprises an accumulator plate, wherein the both sides of the accumulator plate are coated with an active ingredient layer; and an electrode film layer is arranged on the outer side of each active layer. In the invention, two-side pasting technology is adopted and a piece of electrode paper is pressed on the surface of the plate. In a pasting process, paste is uniformly coated on the front and back surfaces of the plate by adopting the two-side pasting technology, so a plate is uniformly stressed; and after the plate is solidified, the plate obtains more active ingredients and the plate is difficult to deform in the solidification process. The electrode film pressed on the surface of the plate can effectively prevent the stripping of the active ingredients, so the cycle service life of the accumulator is prolonged; and meanwhile, the accumulator plate provided by the invention effectively increases the active ingredients on the plate surface, makes the active ingredients on the plate firm, overcomes the defect that the plate has a fewer active ingredients and the defect that the active ingredients are easy to fall in the prior art and prolongs the cycle service life of the accumulator.

Description

technical field [0001] The invention relates to a storage battery pole plate. Background technique [0002] Paste-coated battery plates are currently used as battery plates. Single-side paste technology is generally used, and there are few surface active substances. It is easy to cause the plate to bend during formation, and the active material on the cured plate is easy to fall off. , which reduce the capacity and cycle life of the battery. Contents of the invention [0003] The purpose of the present invention is to provide a pole plate with a reasonable structure, which can effectively prevent the bending of the pole plate and the falling off of the active material during formation, and prolong the cycle life of the battery. [0004] The technical solution of the invention is: the invention includes a storage battery grid, both sides of the storage battery grid are coated with an active material layer, and an electrode film is arranged outside the active layer. [000...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/02H01M4/14H01M4/72H01M4/73

CPCY02E60/126Y02E60/10

Inventor 袁朝勇雷青

Owner JIANGSU OLITER ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com