Biomaterial scaffolds for controlled tissue growth

A biomaterial and tissue growth technology, applied in the field of implants and tissue scaffolds, can solve problems such as uncontrolled and unsuitable for tissue engineering scaffolds, and achieve the effect of optimizing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] experiment

[0103] method

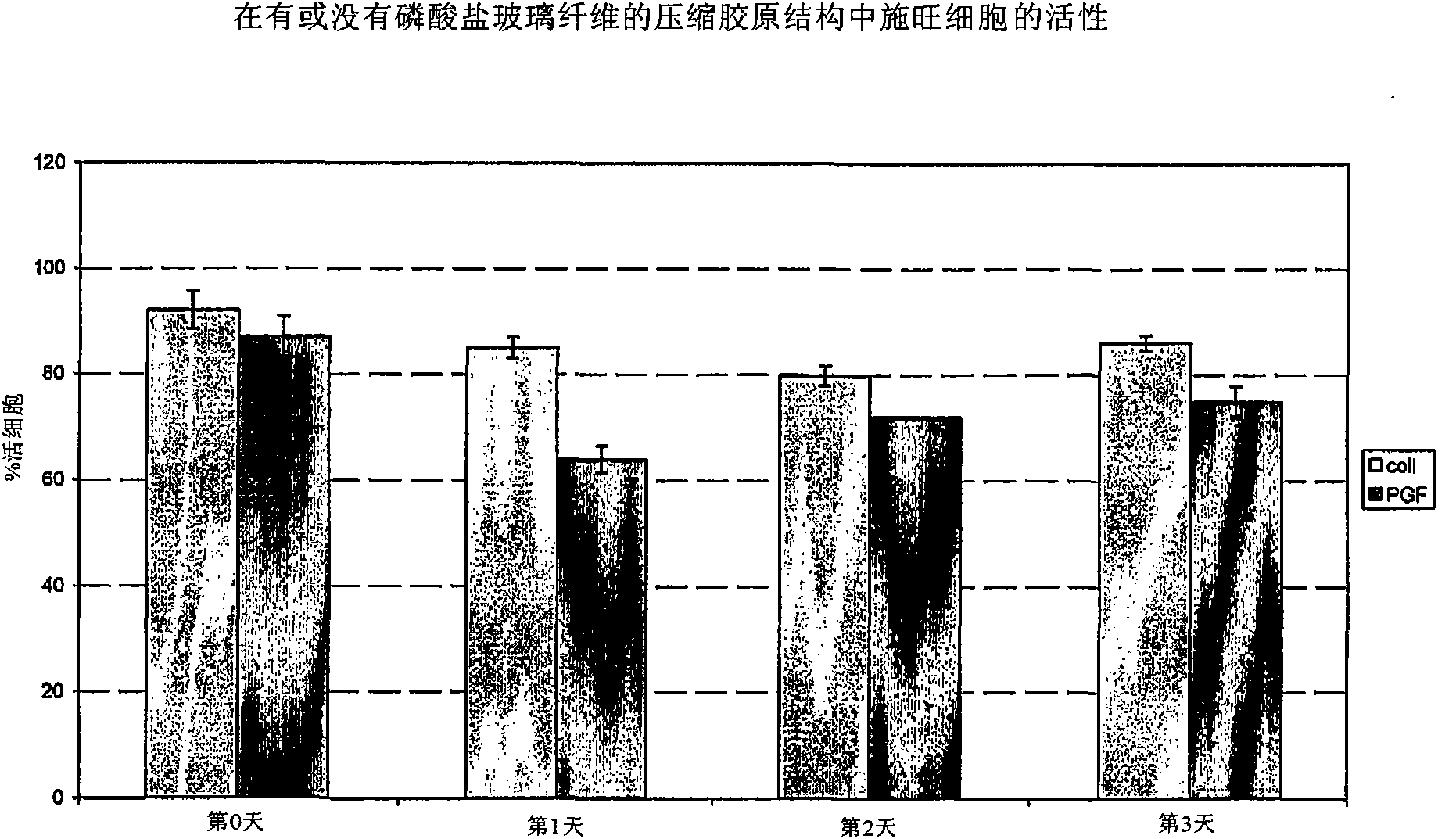

[0104] Conical Fiber Preparation

[0105] The composition ratio is 0.5(P 2 o 5 ):0.25(CaO):(Na 2 O) dissolvable glass fibers with an average diameter of 30-40 μm (dissolving time in distilled water 8-10 hrs; spacing of 170 μm, cut into 2.3×3.5 cm and placed on a cover glass, fixed with autoclave tape. Then the cover glass Put into small Coplin container, then this container fills the Tris buffer solution (pH7.4) of 7ml 1%TRITON x-100 (Sigma). Remove liquid with the rate of 800 μ l per hour from this vial. Remove by the dehydration of ascending alcohol The accumulated hydrogel (for 20, 30, 40, 50, 60 and 90%, 5 minutes × 2; for 96%, 10 minutes × 2; for 100%, 15 minutes × 2) was washed with HMDS ( Hexamethyldisilazide) washing ends.

[0106] electron microscopy

[0107] The slides were left to dry overnight before the glass fibers were gently removed from the coverslips and mounted on sputter-coated stubs using standard procedures. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com