Positioner

A positioner and workbench technology, which is applied in the field of positioners, can solve the problem of increasing the height of the positioner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

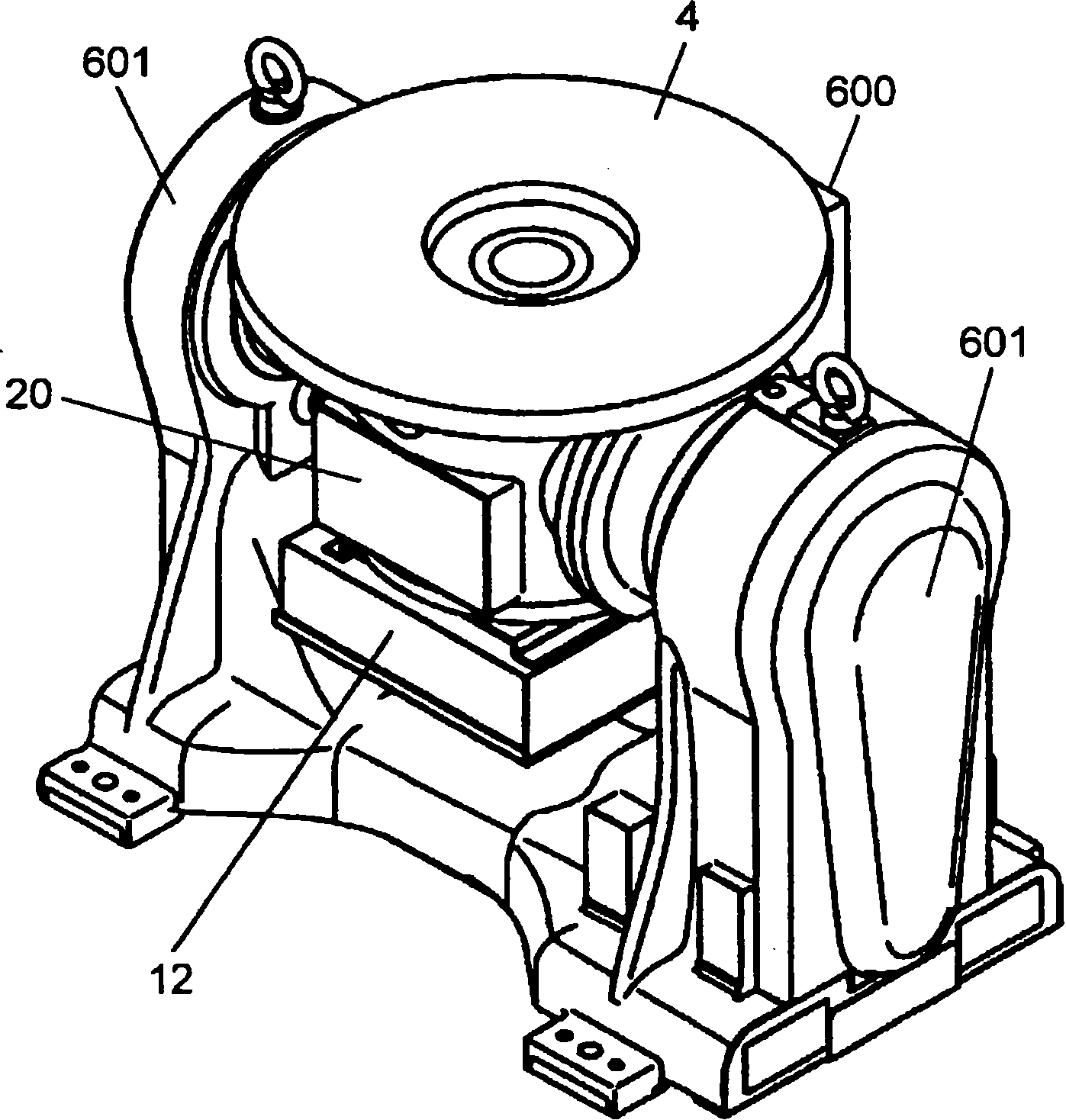

[0076] figure 1 The appearance of the positioner according to Embodiment 1 of the present invention is shown. In the figure, the positioner 600 has a table 4, a frame body 20, and a case 12 as a first case. The positioner 600 is supported by two legs 601 .

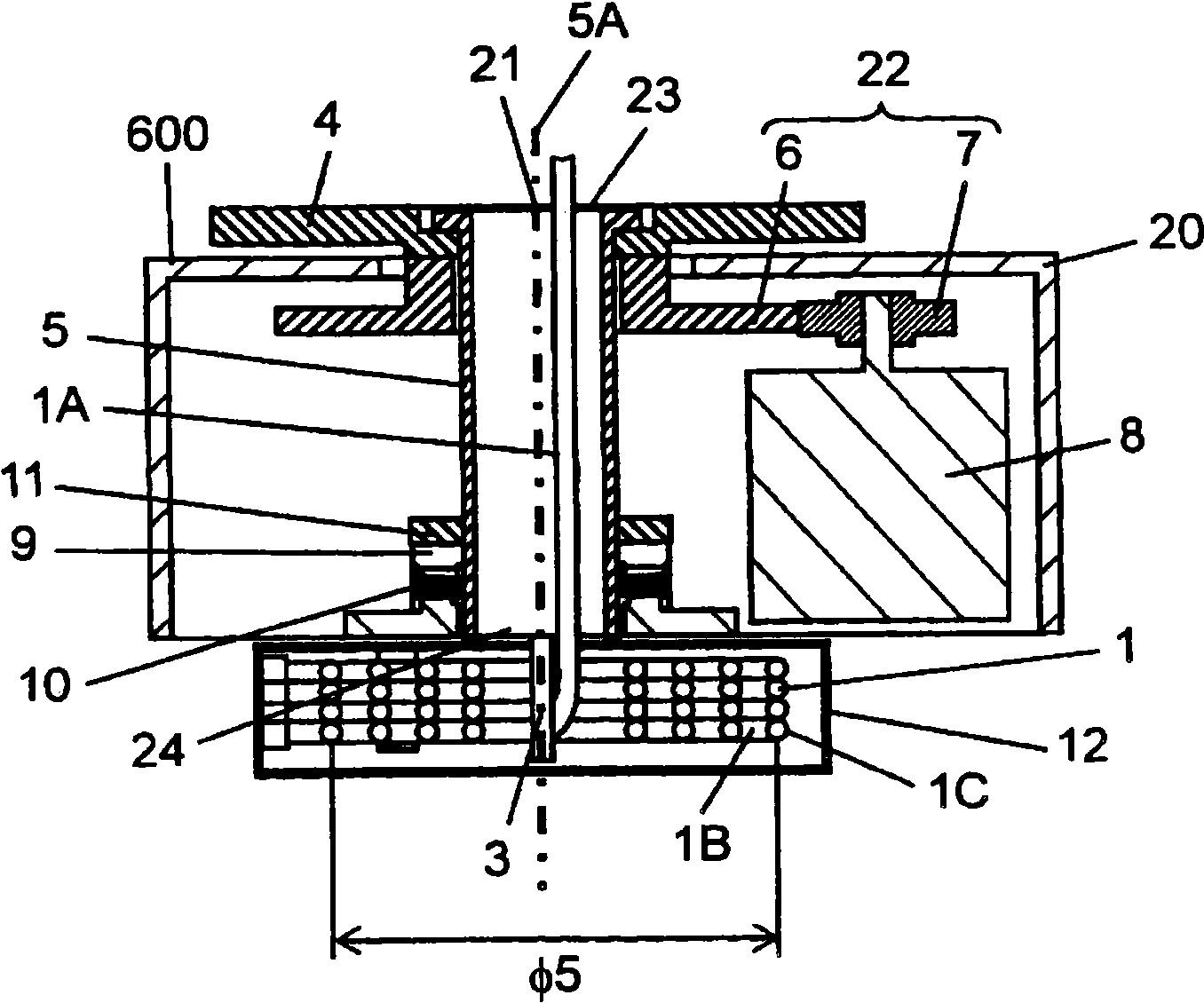

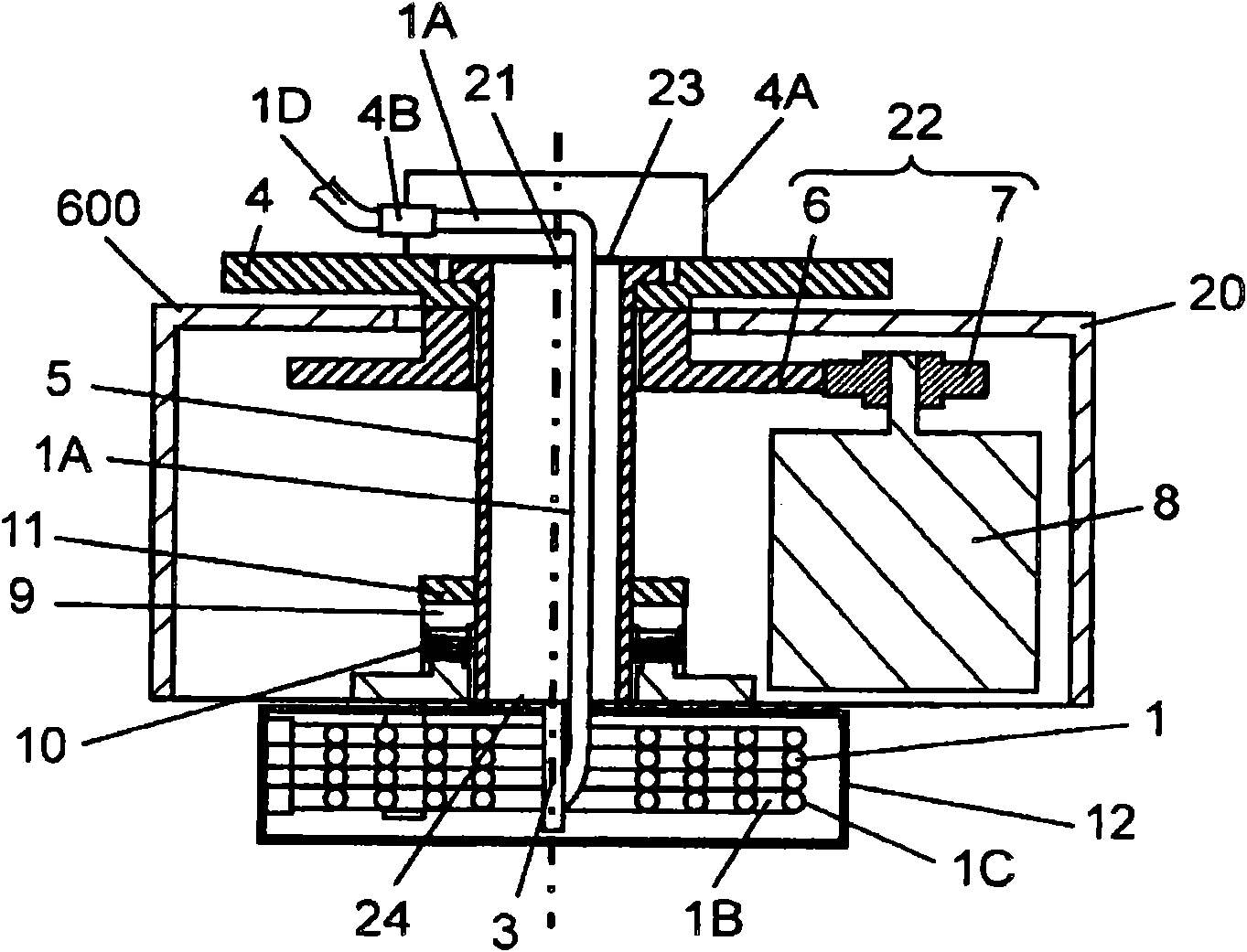

[0077] use Figure 2A The details of the positioner 600 will be described. As shown in the figure, the workbench 4 is arranged on the upper part of the frame body 20 . The table 4 rotates around the rotation center 21 with respect to the housing 20 . Workbench 4 has conductivity. An object to be welded, a jig for attaching the object to the table 4 , and the like are fixed on the table 4 . The motor 8 serving as a driving unit rotates the table 4 in the forward and reverse directions with respect to the rotation center 21 . In Embodiment 1, the positioner 600 has the speed reducer 22 that transmits the power of the motor 8 to the table 4 . The speed reducer 22 has a first gear 6 and a second gear 7 . The first gear...

Embodiment approach 2

[0102] use Figure 10 to Figure 15 Other embodiments of the present invention will be described. However, the same symbols are assigned to the same structures as those in Embodiment 1, and the descriptions are referred to.

[0103] Figure 10 It is a cross-sectional view of a positioner according to Embodiment 2 of the present invention. Figure 11 It is a cross-sectional view of another positioner according to Embodiment 2 of the present invention. Figure 12 It is a perspective view of a fixing tool according to Embodiment 2 of the present invention.

[0104] The positioners 602 and 603 shown in the second embodiment are those in which the fixed shaft 303 as the second winding portion and the winding tube 2 as the second wire are added to the positioner 600 described in the first embodiment.

[0105] and then, Figure 10 The locator 602 is shown with the divider plate 31 inside the housing 12 . The partition plate 31 separates the first wound portion 1B wound around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com