Bending and compression combination-type corrugated steel web formation device

A corrugated steel web and forming device technology, which is applied in the field of bending and molding hybrid corrugated steel web forming devices to achieve the effects of reducing power, improving service life and application range, and avoiding tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

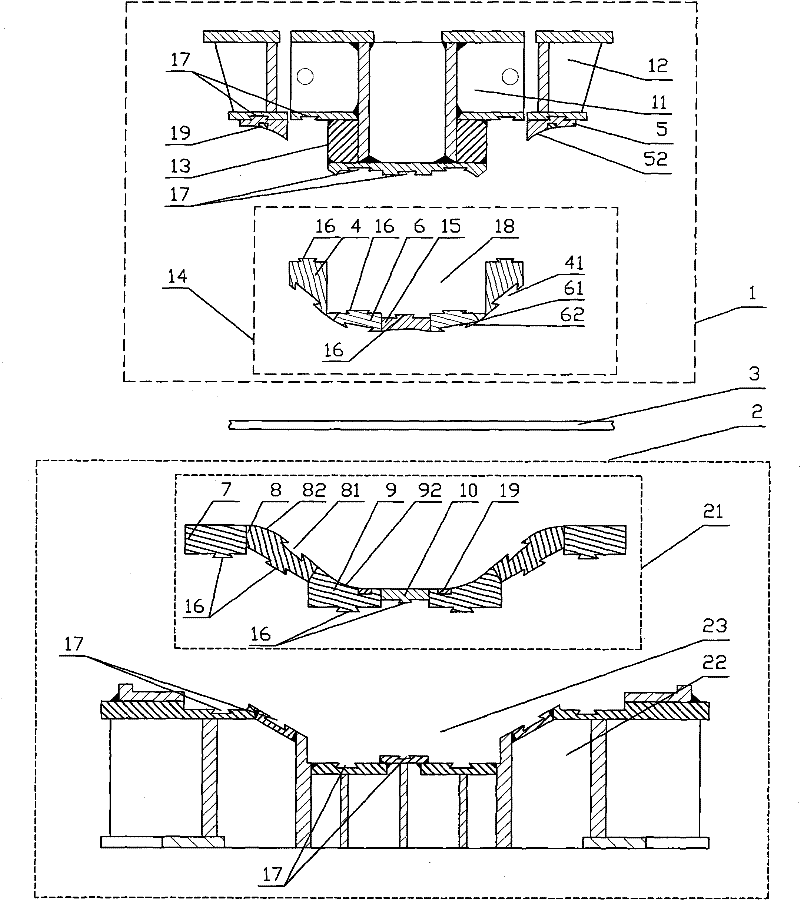

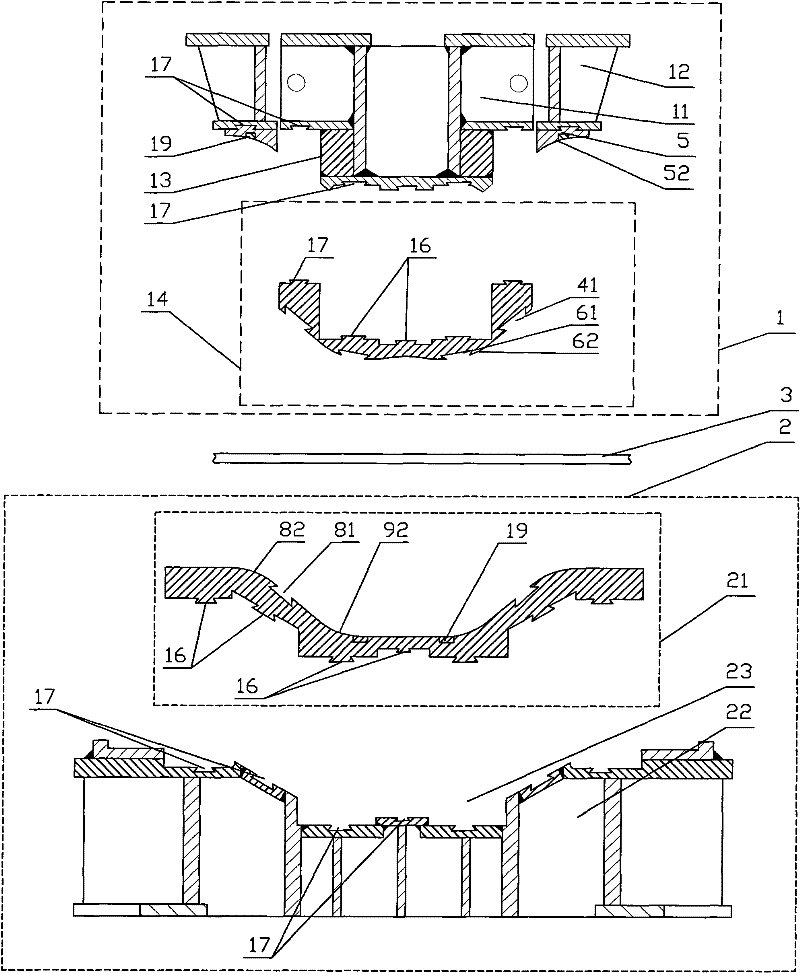

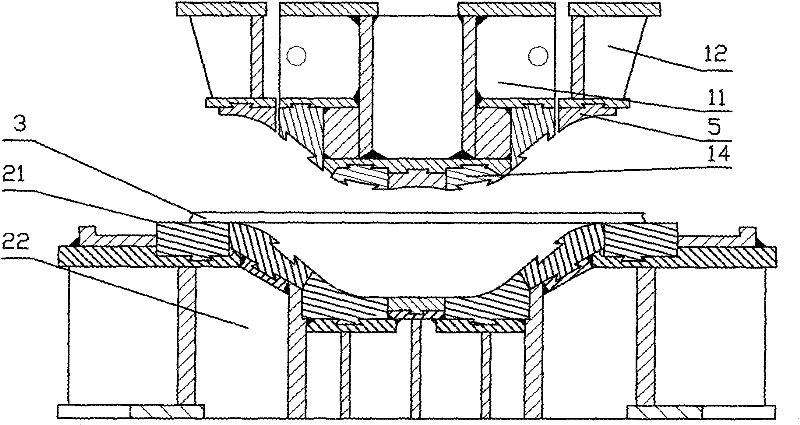

[0024] Bending and molding hybrid corrugated steel web forming device, such as figure 1 , 3 , 4, 5, and 6, including a stamping mechanism 1, a pressure-bearing mechanism 2 arranged below the stamping mechanism 1, the stamping mechanism 1 includes a molding frame 11 and a bending frame 12 arranged on the left and right sides of the molding frame 11, The lower bottom of the bending frame 12 is provided with an arc-shaped wing plate 5; the molding frame 11 is provided with a force application bump 13, and a convex mold 14 is nested on the force application projection 13, and a square groove 18 is opened on the convex mold 14. , its square groove 18 is matched with the force-applying bump 13; the pressure-bearing mechanism 2 packs the lower mold frame 22 and the concave mold 21 arranged on the lower mold frame 22, and the lower mold frame 22 is provided with a matching concave mold 21 The pressure-bearing groove 23 , the die 21 is nested on the pressure-bearing groove 23 , and t...

Embodiment 2

[0038] Bending and molding hybrid corrugated steel web forming device, such as figure 2 , 3 , 4, 5, and 6, including a stamping mechanism 1, a pressure-bearing mechanism 2 arranged below the stamping mechanism 1, the stamping mechanism 1 includes a molding frame 11 and a bending frame 12 arranged on the left and right sides of the molding frame 11, The lower bottom of the bending frame 12 is provided with an arc-shaped wing plate 5; the molding frame 11 is provided with a force application bump 13, and a convex mold 14 is nested on the force application projection 13, and a square groove 18 is opened on the convex mold 14. , its square groove 18 is matched with the force-applying bump 13; the pressure-bearing mechanism 2 packs the lower mold frame 22 and the concave mold 21 arranged on the lower mold frame 22, and the lower mold frame 22 is provided with a matching concave mold 21 The pressure-bearing groove 23 , the die 21 is nested on the pressure-bearing groove 23 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com