Quenching gas recycling system

A technology of gas circulation and gas pipeline, which is applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problem of large nitrogen consumption, achieve the effect of solving large gas consumption, improving resource utilization, and realizing automatic control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

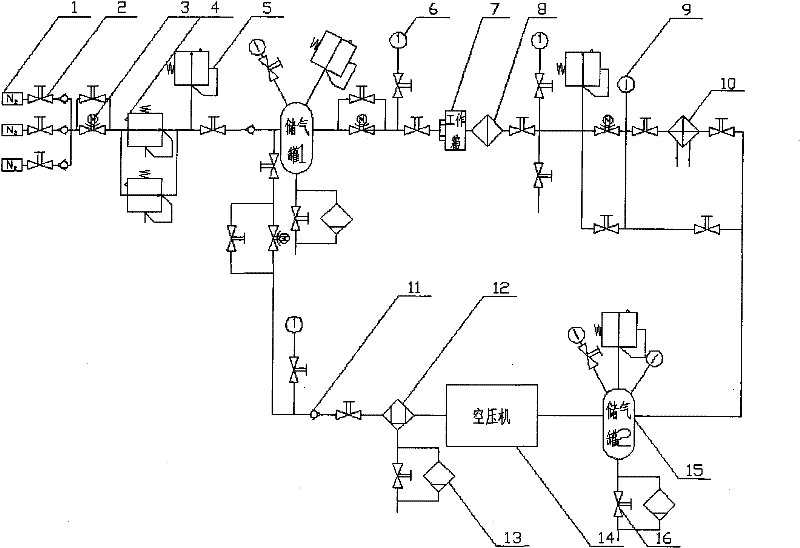

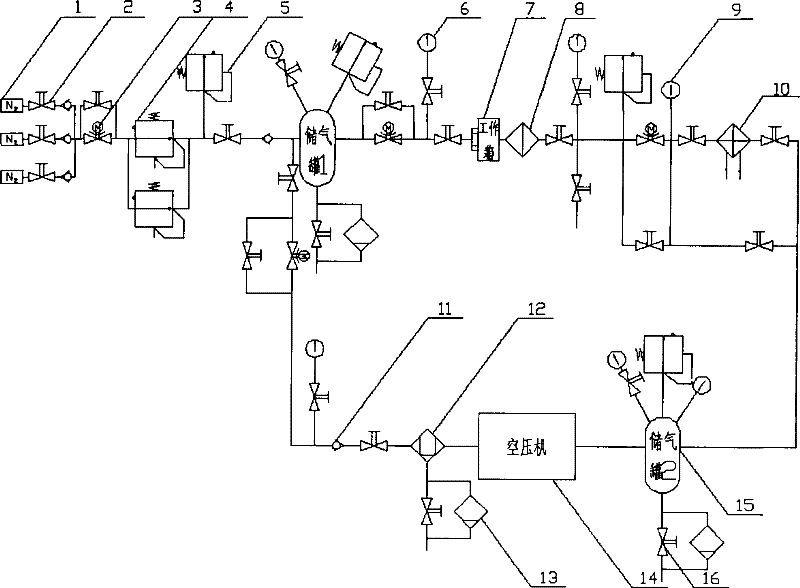

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] The quenching gas recycling system consists of ball valves 2 and 3, pressure regulating valve 4, safety valve 5, check valve 11, drain valves 13 and 16, gas storage tank 117, gas storage tank 215, nitrogen cylinder 1, filter 8, Cooler 10, air compressor 14, quenching work box 7, etc., the specific installation method is as follows: use three air pipes to connect three nitrogen cylinders 1, the other end of the three air pipes is connected to three manual ball valves 2, and manually Three check valves 11 are connected in series at one end of the ball valve 2, three gas delivery pipes are connected together by a four-way connection, another connection of the four-way connection is connected with a gas delivery pipe, which is used to connect the parallel part of the electric ball valve 3 and the manual ball valve 2, Use four air pipes to connect the two parallel pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com