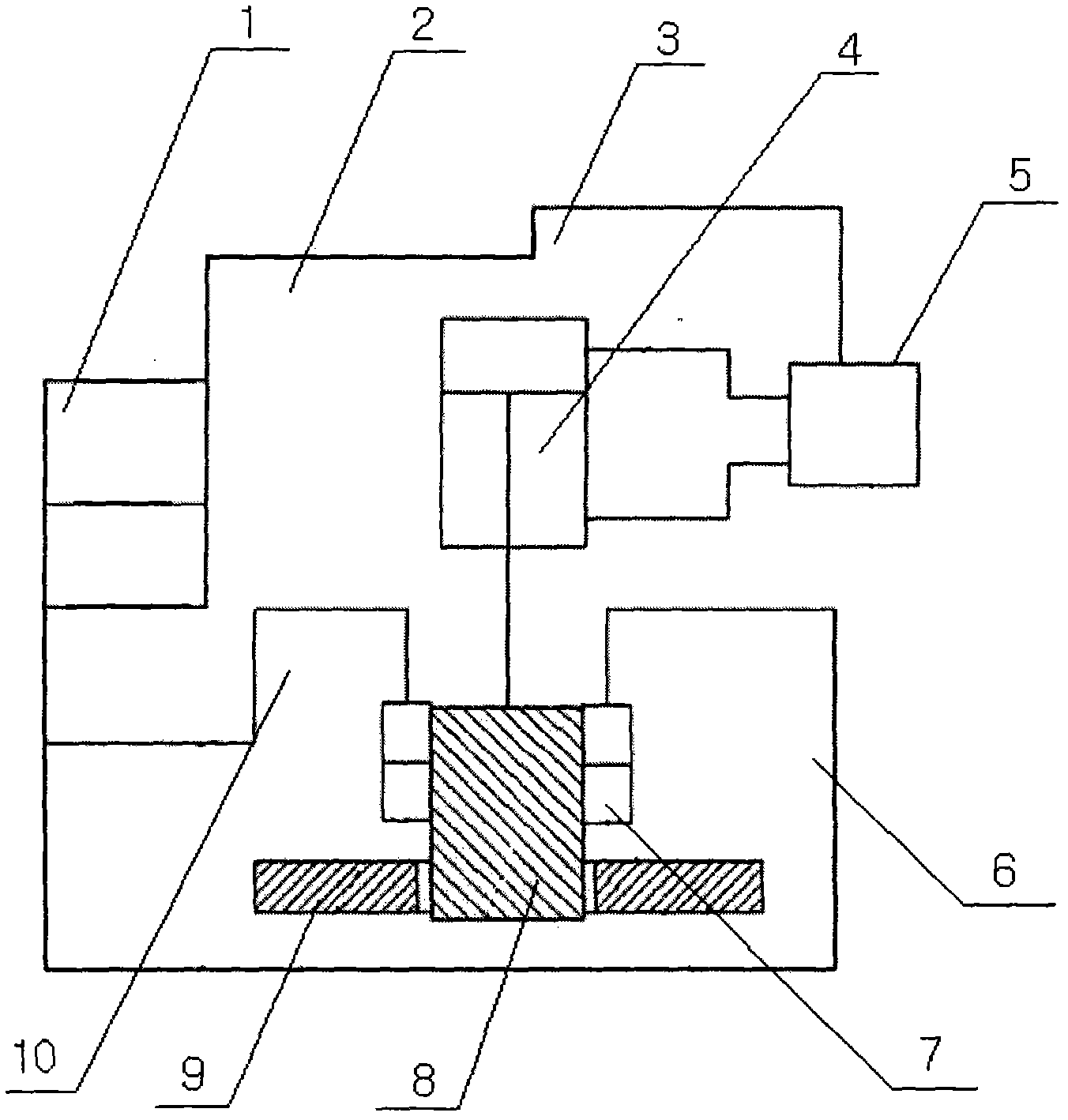

Structure of hydraulic press

A hydraulic press and liquid flushing technology, which is applied to forging presses, forging presses, forging/pressing/hammer devices, etc., can solve the problems of large energy consumption and complex structure, and achieve the effect of less energy consumption, complex structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The structure of the hydraulic press has a liquid flushing cylinder (10), which is connected with the blank holder oil cylinder (7) through the slide block (8), and a blank blank slide block ( 9), the blank holder slider (9) supplies the flushing cylinder (10) from the blank holder cylinder (7) through the oil tank (6) and the slider (8), and the main oil cylinder ( 4), the main oil cylinder (4) is connected with the host system (5), the host system (5) is connected with the flow door (3), the flow door (3) is connected with the two-way control door (2), and the two-way control door (2) Connect with control door (1), and control door (1) is installed on the side surface of flushing cylinder (10) and the lower end of two-way control door.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com