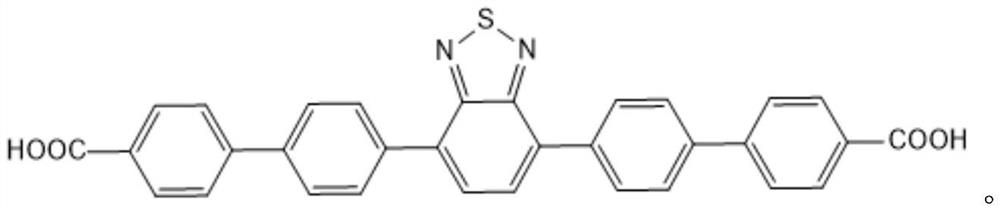

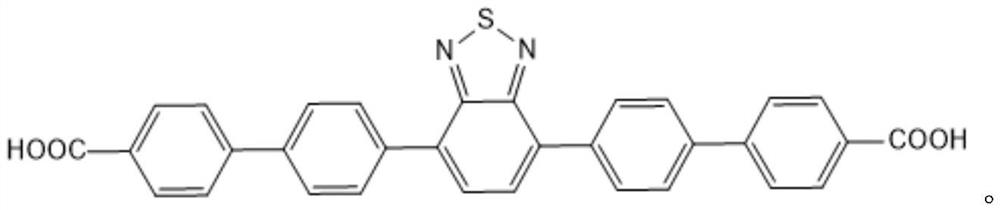

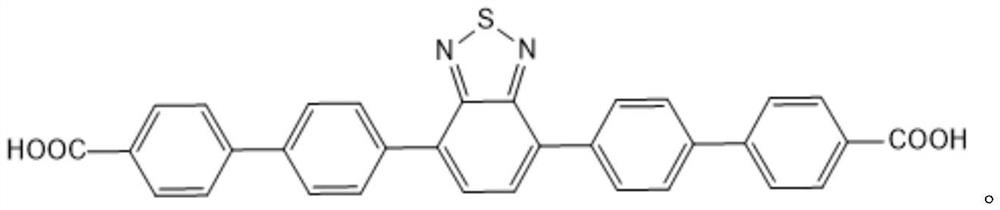

Preparation method and application method of benzothiadiazole-based large-aperture MOF material

A benzothiadiazole and MOF technology, which is applied in the field of preparation and application of chemical materials, can solve the problems of long time consumption and high energy consumption, and achieve the effects of simple preparation process, suitable for mass production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of the large aperture MOF material based on benzothiadiazole, described method comprises the steps:

[0036] Step 1: Dissolve a certain amount of metal salt and ligand in a solvent to obtain solution A and solution B;

[0037] Weigh 0.2-2.0mmol metal salt, dissolve it in N,N-dimethylformamide to obtain solution A;

[0038] Weigh 0.1-2.0 mmol of the ligand and dissolve it in N,N-dimethylformamide to obtain solution B;

[0039] Among them: the molar ratio of metal salt and ligand is listed as 2 to 3:1;

[0040] Metal salts are active metals of periods 4, 5, and 6 in the periodic table and metal elements of the main group II to VIA, preferably Sn, Zn, Ga, Ge, In, Sb, Tl, Pb, Bi, Po, Ti, Al, Salts prepared by one or more of Ba, Rh, Ru, Ni, Cu, Fe, Cr, Co, Pd, Mn, V, Sc, Cd, Ag, Tc, Mo, Nb, Zr, Y;

[0041] Metal salts are nitrates, chlorides and acetates of transition metals and nitrates and chlorides of rare earth metals;

[0042] Metal salt...

Embodiment 1

[0063] Weigh 0.2mmol of nickel nitrate hexahydrate and dissolve in 10mL of DMF solution, solution A;

[0064] Weigh 0.1mmol of H 2 L and dissolved in 20mL of DMF solution, solution B;

[0065] Mix solution A and solution B, and ultrasonic 20min, then pack in the liner of tetrafluoroethylene, be placed in the reactor, finally reactor is placed in the vacuum oven;

[0066] Start heating in the drying oven, heat to 120°C within 3 minutes, and keep it for 24 hours;

[0067] After reaching the holding time, cool down to room temperature at a rate of 0.08°C / min, and take out the material;

[0068] Dry the taken-out material at a temperature of 50°C for 12 hours. After drying, a new type of MOF material is obtained;

Embodiment 2

[0070] Weigh 3mmol of zinc nitrate nonahydrate and dissolve in 10mL of DMF solution, solution A;

[0071] Weigh 1mmol of H 2 L and dissolved in 20mL of DMF solution, solution B;

[0072] Mix solution A and solution B, and ultrasonic 40min, then pack in the liner of tetrafluoroethylene, be placed in the reactor, finally reactor is placed in the vacuum oven;

[0073] Start heating in the drying oven, heat to 130°C within 3 minutes, and keep it for 48 hours;

[0074] After reaching the holding time, cool down to room temperature at a rate of 0.9°C / min, and take out the material;

[0075] Dry the taken-out material at a temperature of 60°C for 18 hours. After drying, a new type of MOF material is obtained;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com