Combined kitchen fume exhaust cover

An oil fume exhausting and combined technology, which is applied in the field of large oil fume exhaust hoods, can solve the problems of low production efficiency, inconvenient processing, inconvenient transportation, etc., and achieve the effects of convenient production and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

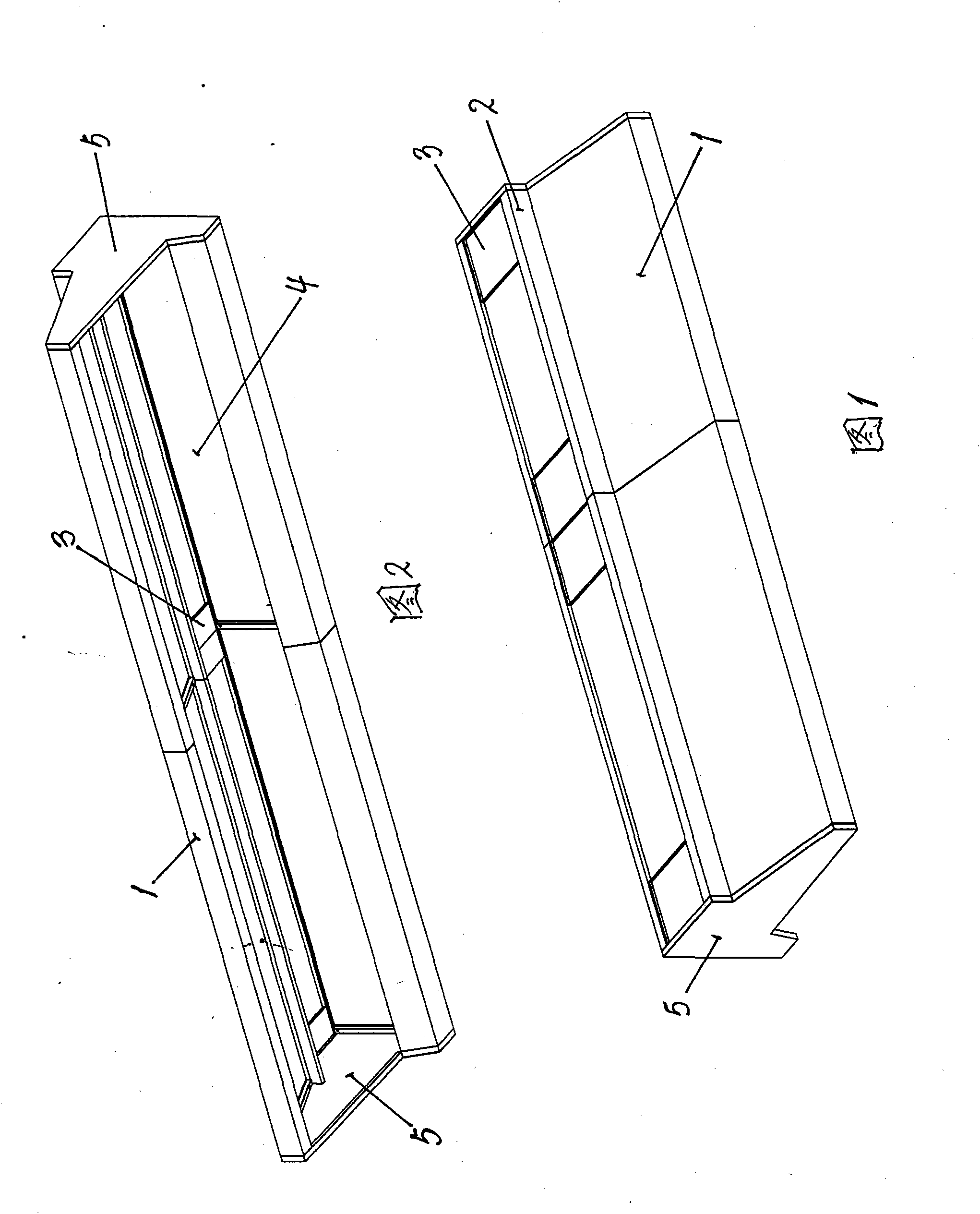

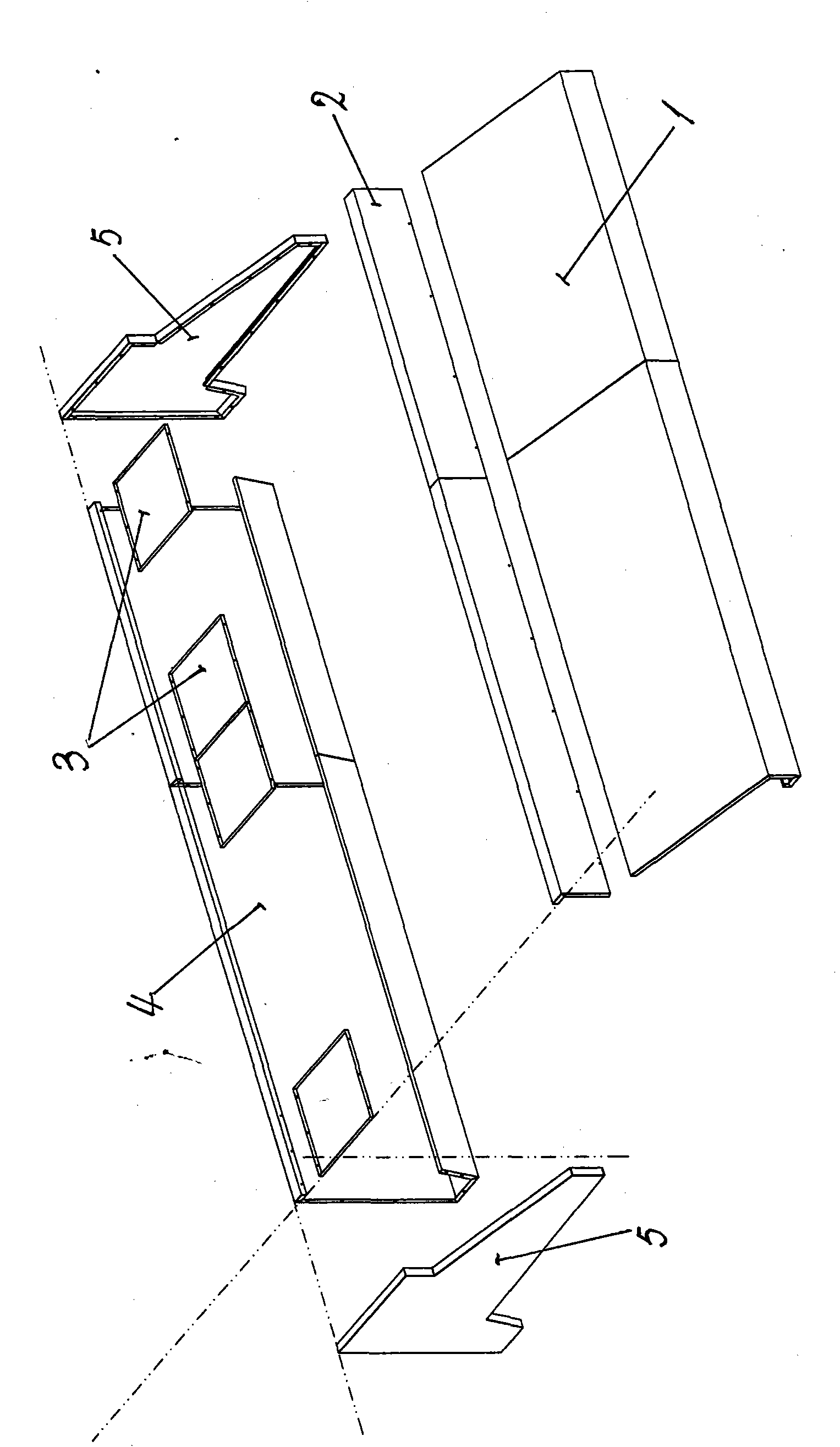

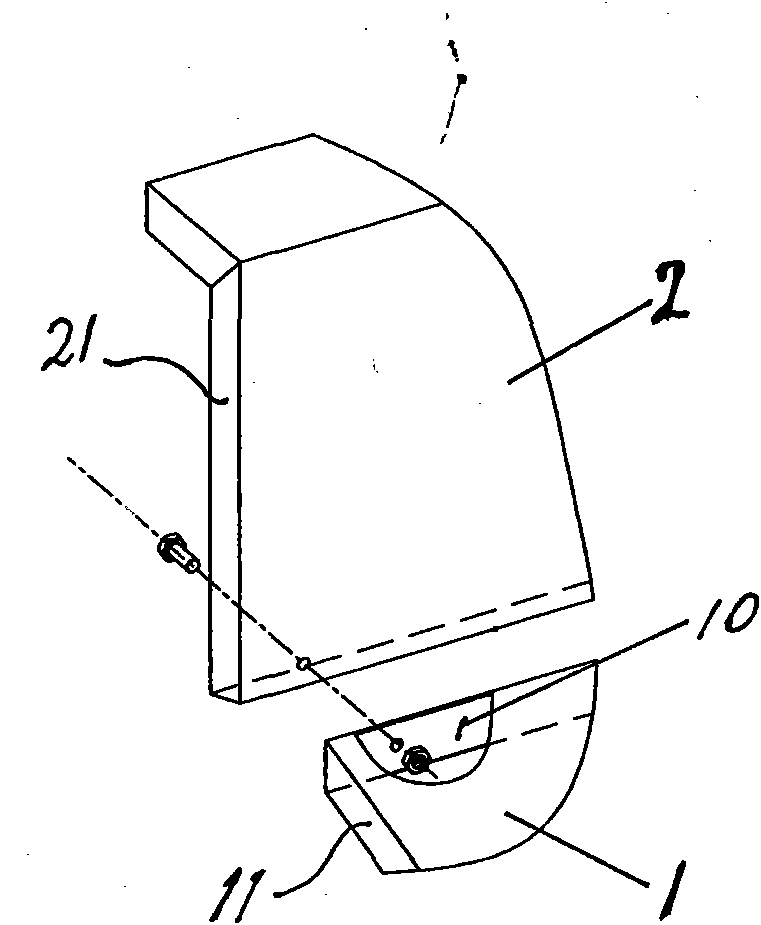

[0013] The oil exhaust hood of the present invention is composed of a front cover plate 1, an upper cover plate 2, a top cover plate 3, a rear cover plate 4, and left and right end cover plates 5. The rear side of the front cover plate 1 is provided with a flange 10 and an upper cover plate 2. The board surfaces are fixedly connected by bolts. The top cover plate 3 is arranged at multiple intervals. The space between the two top cover plates 3 is an exhaust port. The four sides of the top cover plate 3 are provided with flanges 30. The front and rear ends of the top cover plate 3 are formed The flanging 30 is fixedly connected with the flanging 20,40 bolts on the top cover plate 2 and the rear cover plate 4 respectively, the end cover plate 5 is provided with a flanging 50, the front cover plate 1, the upper cover plate 2, the rear cover plate 4 Flanges 11, 21, 41 are provided on the left and right sides, and the end cover plate 5 is fixedly connected with the side end flanges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com