Double-energy storage operating mechanism of single operating shaft

An operating mechanism, dual energy storage technology, applied in the contact drive mechanism, power device inside the switch, emergency protection device, etc., can solve the problems of low reliability, circuit breaker tripping, ATSE not switching, etc., to achieve reliability High, novel structure, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

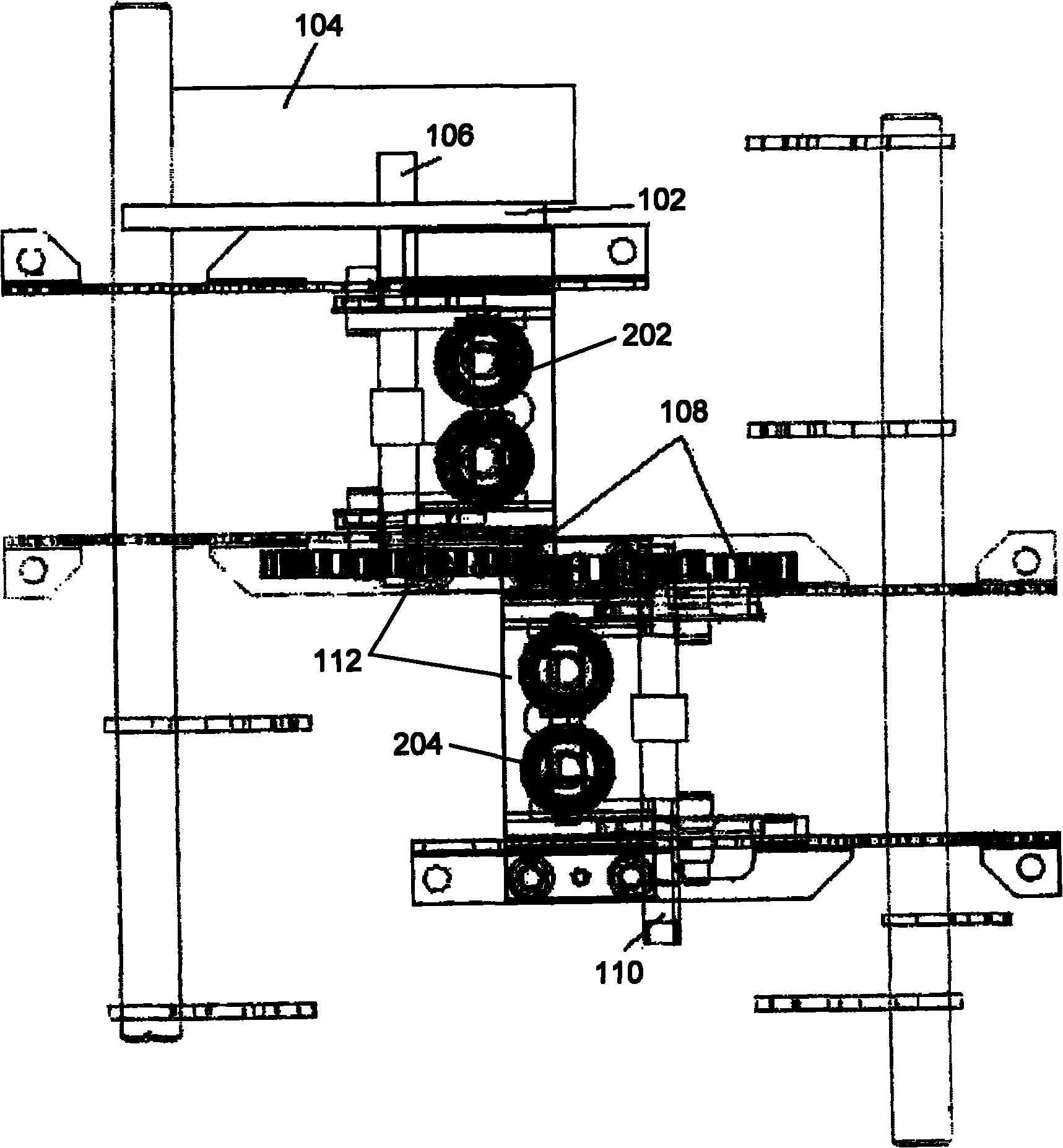

[0025] refer to figure 1 As shown, the present invention proposes a double energy storage operating mechanism with a single operating shaft, which is used for automatic switching electrical appliances, including:

[0026] The operating handle 102 and the operating motor 104, the operating handle 102 and the operating motor 104 are located on the first side of the mounting plate of the operating mechanism of the automatic transfer switch electrical appliance, the operating handle 102 and the operating motor 104 are inserted into the first operating cam spindle 106 of the operating mechanism, The first operating cam main shaft 106 is driven to rotate by the operating handle 102 or the operating motor 104 .

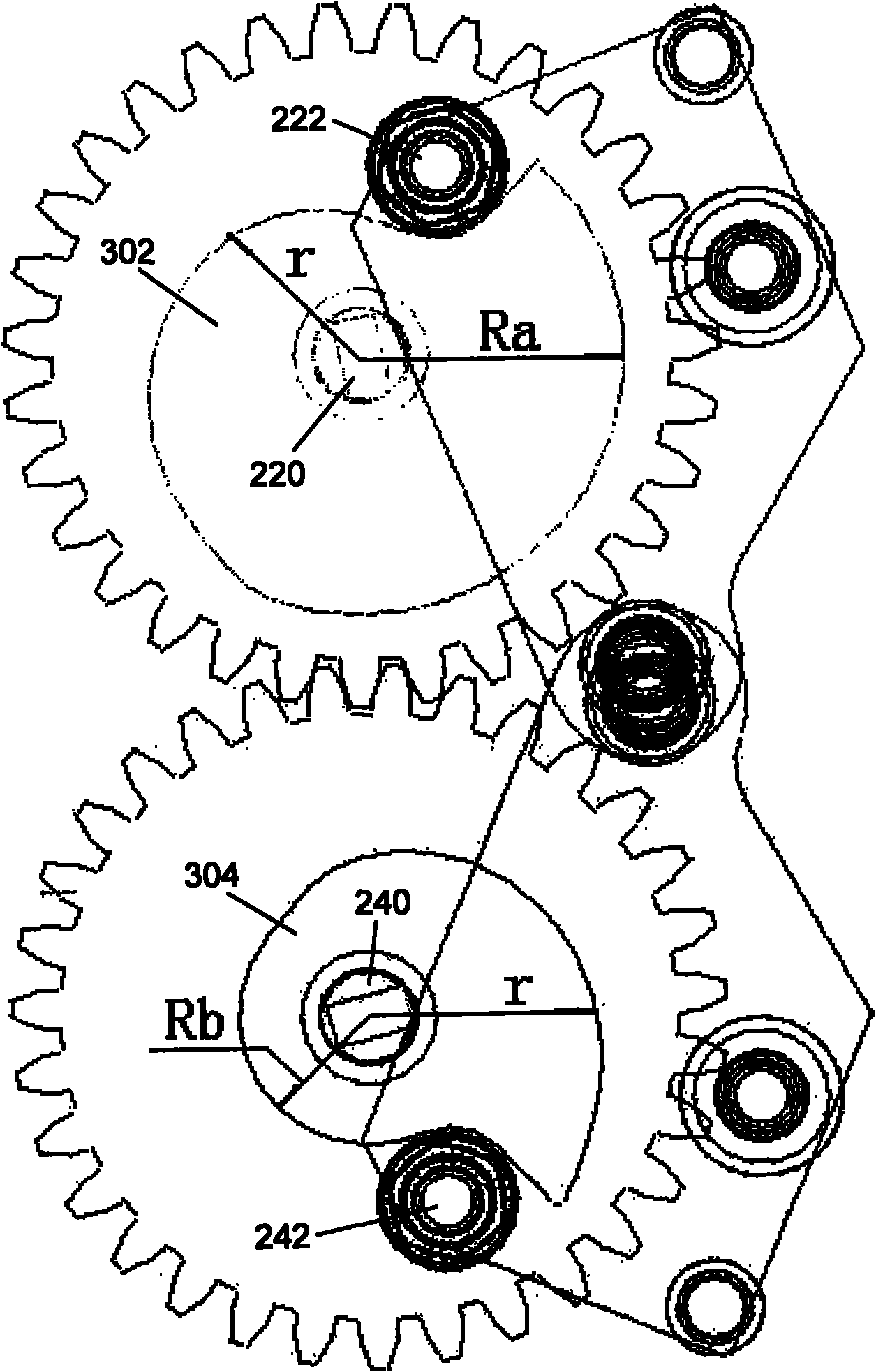

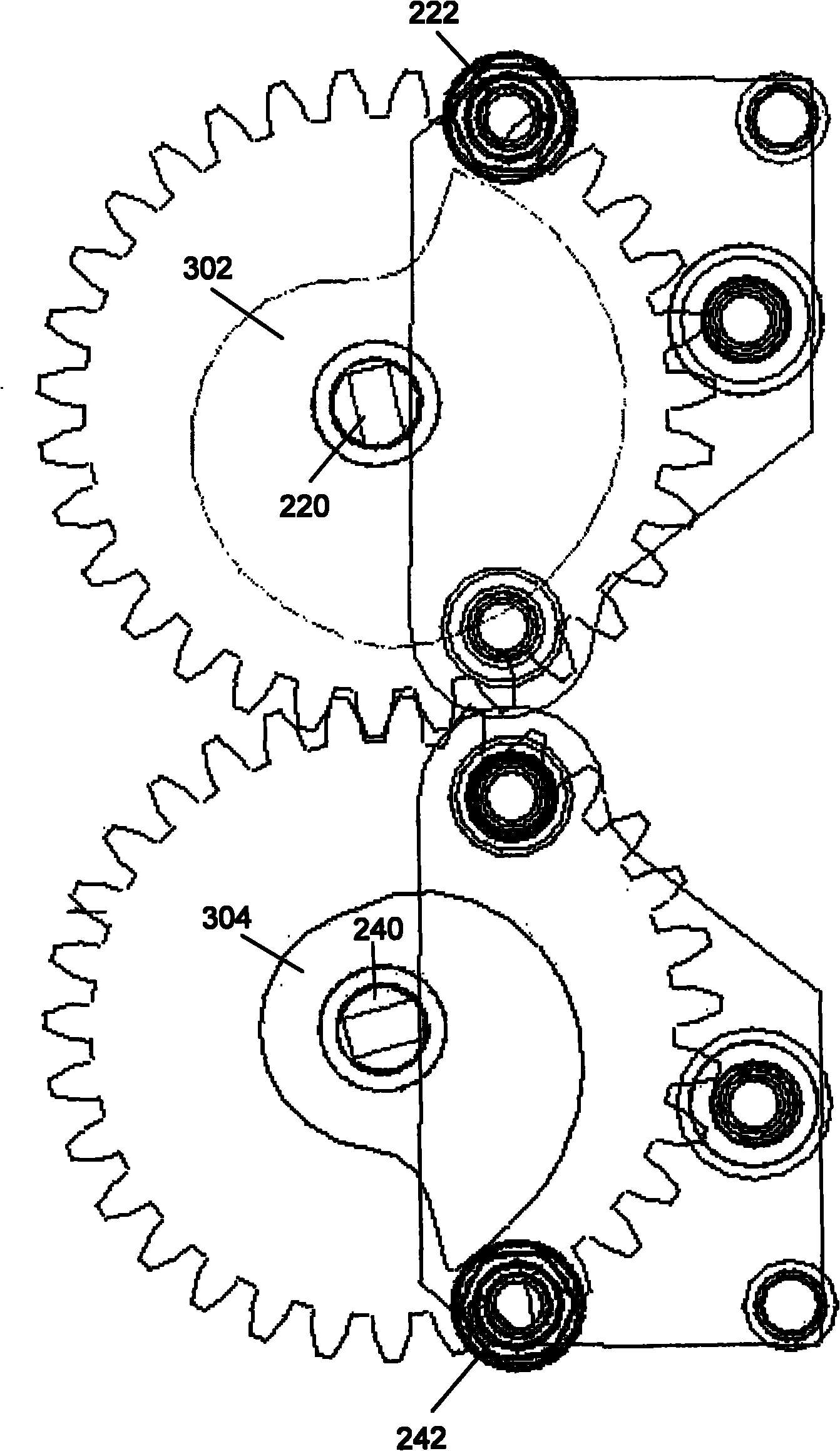

[0027] The transmission gear 108 comprises two gears that mesh with each other. The transmission gear 108 is positioned at the second side of the mounting plate of the operating mechanism. The transmission gear 108 connects the first operation cam main shaft 106 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com