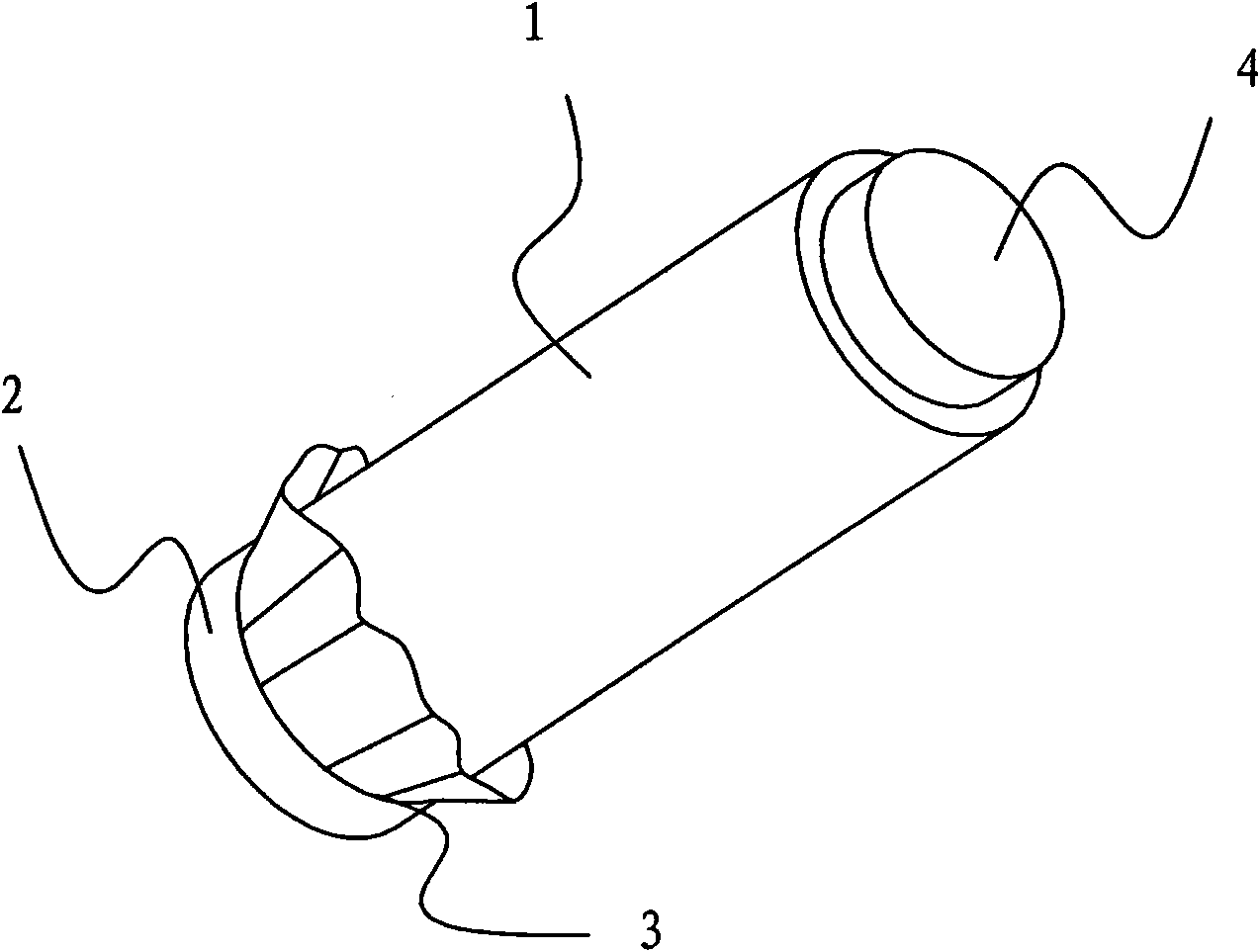

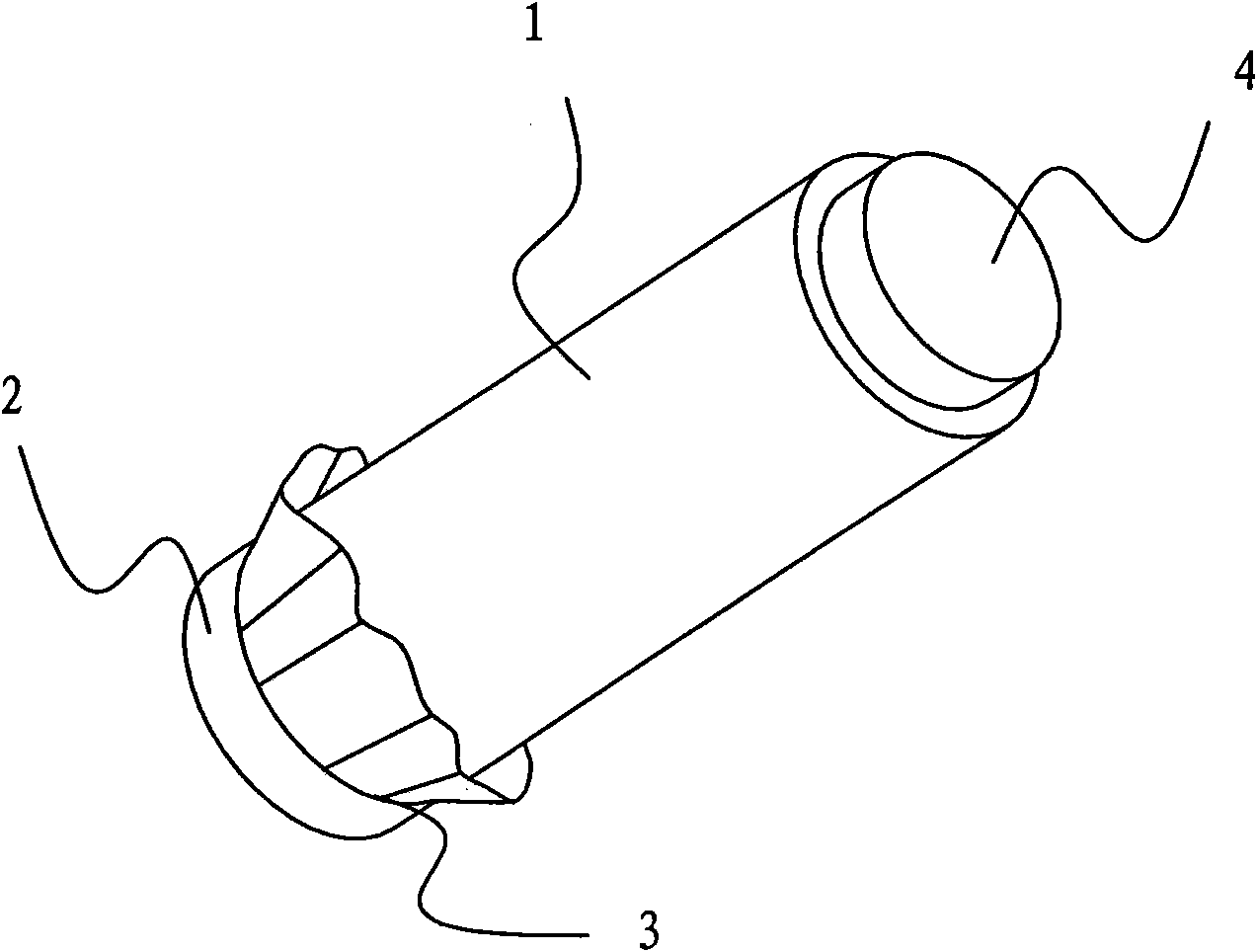

Corn hybrid seed production and pollination tool and pollination method using same

A technology of hybrid seed production and pollination tools, which is applied in the field of plant artificial pollination, can solve the problems of low seed setting rate, uneven pollen distribution, and low work efficiency in corn hybrid seed production, and achieve high corn seed setting rate, improved work efficiency, and energy saving. The effect of pollen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] When the corn ear filaments grow to 1-2 cm, the bamboo tube containing corn pollen is tilted to form a 40-degree angle with the horizontal plane, and the end with the screen is located below, and the pollen volume accounts for half of the cavity volume of the bamboo tube. During pollination, the bottom end of the bamboo tube is set at 4 cm directly above the ear of corn, and then the outer wall of the bamboo tube is knocked once to complete the pollination.

Embodiment 2

[0023] When the corn ear filaments grow to 1-2 cm, the bamboo tube containing corn pollen is tilted to form an angle of 45 degrees with the horizontal plane, and the end with the screen is located below, and the pollen volume accounts for half of the cavity volume of the bamboo tube. During pollination, the bottom end of the bamboo tube is set at 4 cm directly above the ear of corn, and then the outer wall of the bamboo tube is knocked once to complete the pollination.

Embodiment 3

[0025] When the corn ear filaments grow to 1-2 cm, the bamboo tube containing corn pollen is tilted to form an angle of 50 degrees with the horizontal plane, and the end with the screen is located below, and the pollen volume accounts for half of the cavity volume of the bamboo tube. When pollinating, the bottom of the bamboo tube is set at 5 cm directly above the ear of corn, and then the outer wall of the bamboo tube is knocked once to complete the pollination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com