Rotary type ceramic water purifier

A rotary, water purifier technology, applied in chemical instruments and methods, mobile filter element filters, filtration and separation, etc., can solve problems such as valve leakage, product water quality safety, hidden dangers, etc., to ensure cleanliness and improve water production. ability, the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

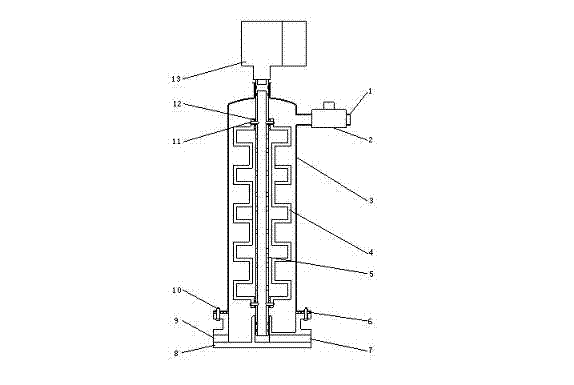

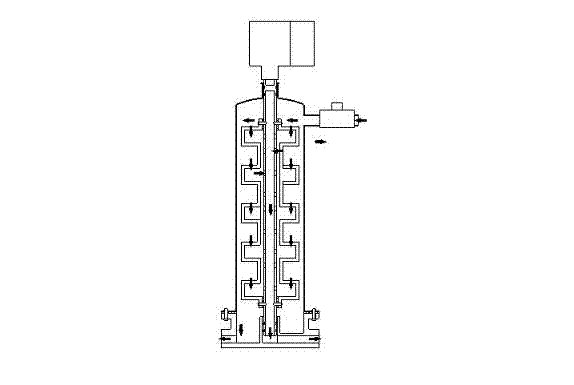

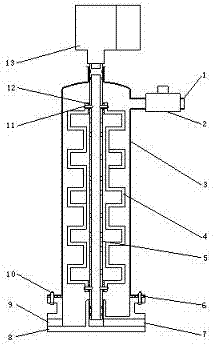

[0025] Such as figure 1 As shown, the rotary ceramic water purifier of this embodiment includes a casing, a ceramic filter assembly, and a rotary control and actuator, wherein the casing is composed of a cylinder body 3 and a base 8, the upper part of the cylinder body is provided with a water inlet 1, and the base is provided with The water production port 7 and the waste water discharge port 9, the cylinder body and the base are connected by connecting bolts 10, and there is a sealing ring 6 between the cylinder body and the base; the ceramic filter assembly includes a "corrugated" shaped ceramic filter piece 4 and a central tube 5, and the ceramic filter piece 4. The filter element is fixed on the central tube 5 by the fixing screw 11. There is a gasket 12 between the ceramic filter 4 and the central tube 5; there are several small holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com