Solid particle male die forming mold with movable brake beads and radial thrust

A technology of solid particles and radial thrust, applied in the field of stamping dies, which can solve the problems that the resistance of variable drawbeads cannot be changed and the shape of punches cannot be changed, so as to achieve the effect of effective product quality, changeable shape and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

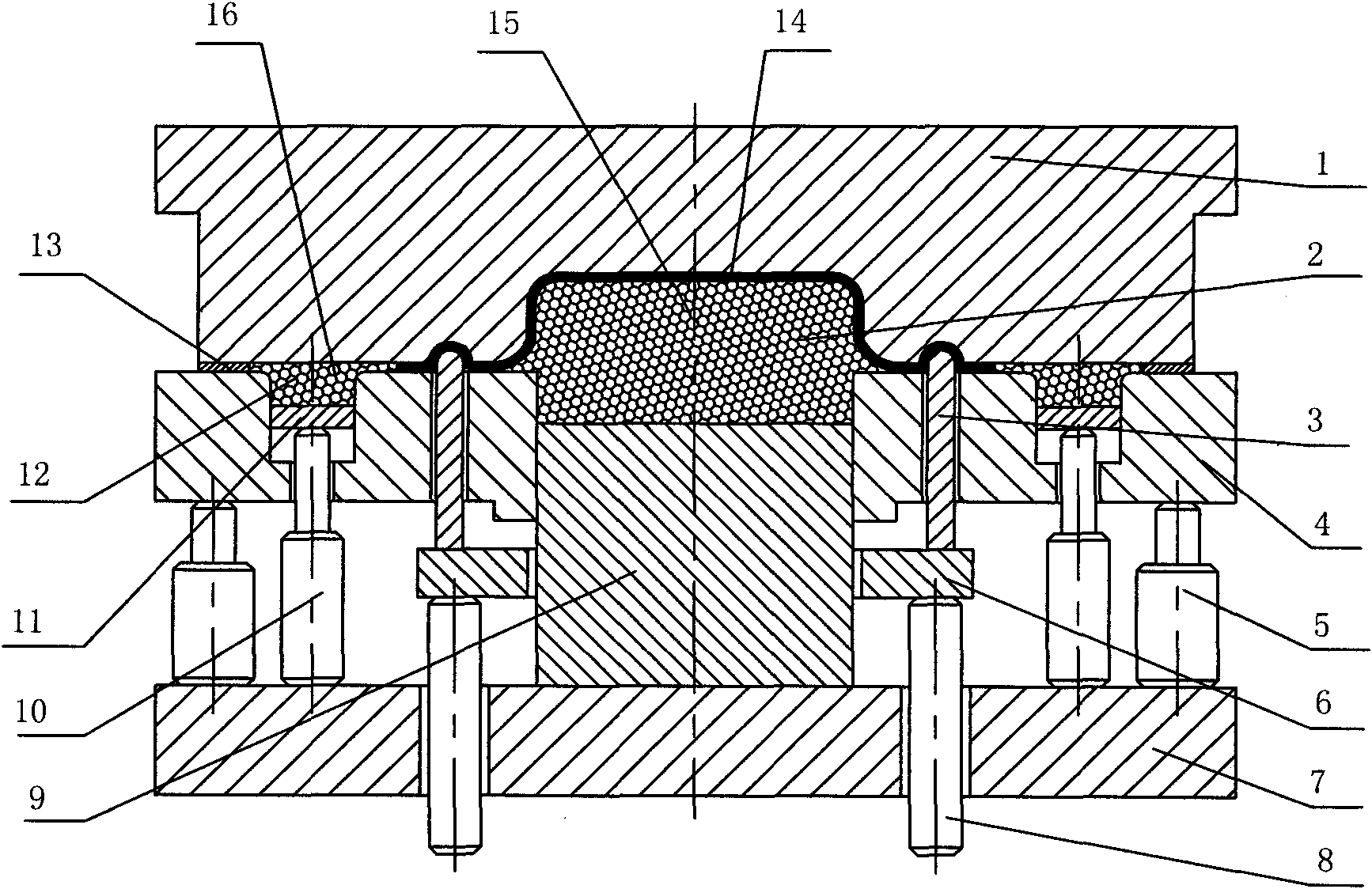

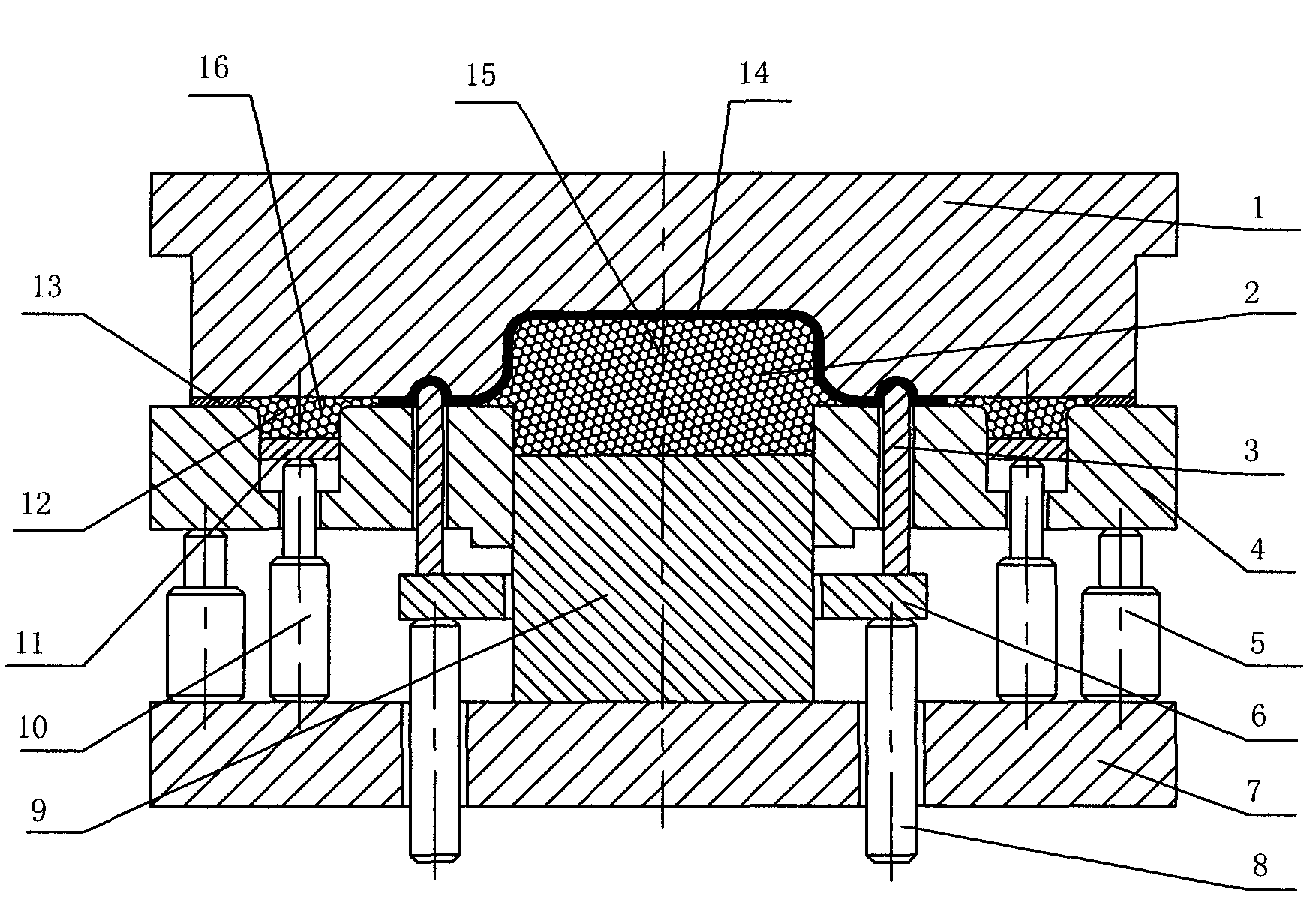

[0017] see figure 1 , shown as a solid particle punch forming die with movable drawbeads and radial thrust in the present invention, including a die 1, a formed solid particle 2, a drawbead 3, a blank holder 4, and a compression cylinder 5, Backing plate 6, lower mold base 7, ejector rod 8, briquetting block 9, ejector cylinder 10, top plate 11, radial solid particles 12, sealing plate 13, blank 14, etc.; die 1 is installed on the inner slider (Fig. not shown in), can move, the blank 14 is molded in the die cavity in the die 1; In the hole of the blank holder 4 , the blank holder 4 moves up and down relative to the pressing block 9 . The pressing cylinder 5 and the jacking cylinder 10 are also installed on the lower mold base 7, and the working end of the pressing cylinder 5 is in contact with the lower surface of the blank holder 4 to withstand the lower surface of the blank holder 4; The pressing force required by the edge ring 4. The working end of the jacking cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com