Carriage supporting device of traverse table of forging press

A technology for moving a worktable and a forging press, applied in the field of forging presses, can solve the problems of easy wear, large surface pressure, small area, etc., and achieve the effects of reducing the surface pressure, improving the contact condition, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

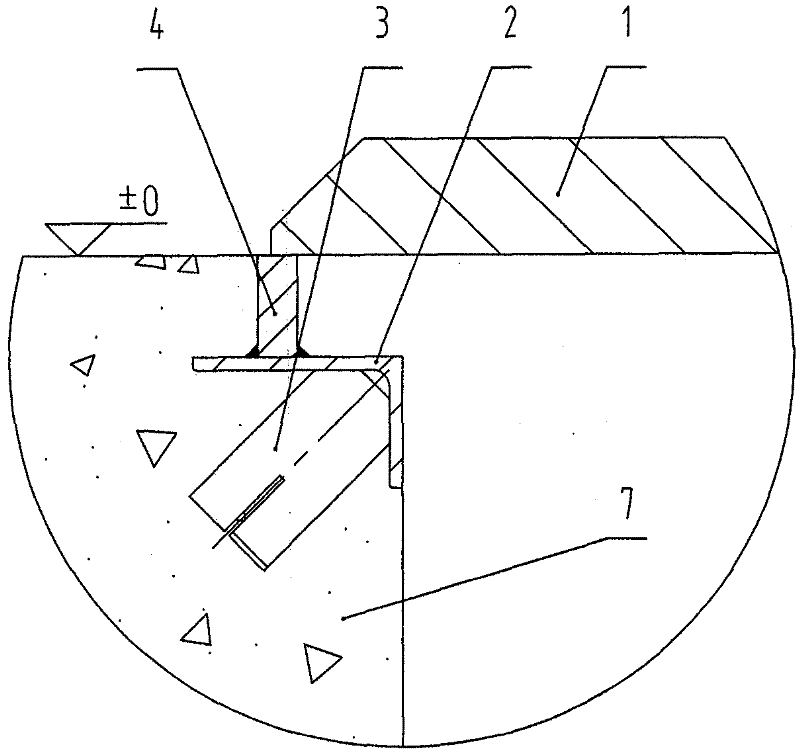

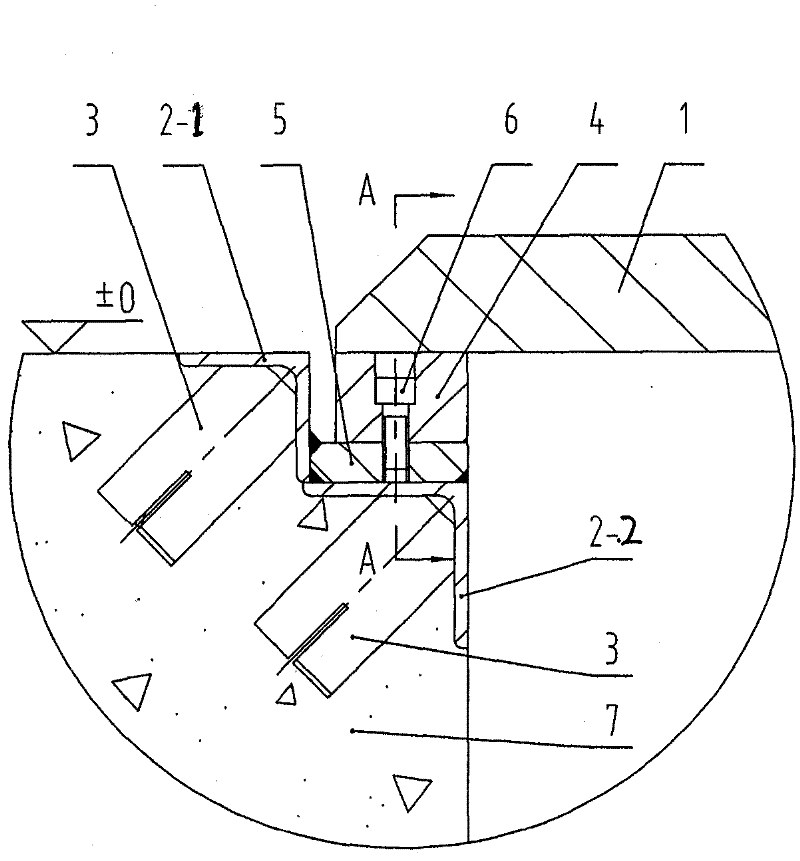

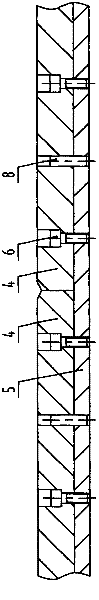

[0018] like figure 2 As shown, a carriage supporting device for a mobile workbench of a forging press includes: carriage 1, slide rail 4, angle steel 2, anchor bars 3, and foundation 7, and the slide rail 4 is made of cast iron material with low hardness. Each length is 2m~2.5mm, the width is not less than 0.3m, and is fixed on the bottom plate 5 by screw 6.

[0019] In order to prevent the friction force of the carriage 1 from causing the screw 6 to bear the shear force, a pin 8 is arranged between the slide rail 4 and the bottom plate 5 .

[0020] The angle steel 2 is two: the upper angle steel 2-1 and the lower angle steel 2-2, and the two angle steels are vertically arranged up and down, that is: the vertical side of the upper angle steel 2-1 is perpendicular to the horizontal side of the lower angle steel 2-2 .

[0021] The upper angle steel 2-1 and the lower angle steel 2-2 are respectively fixed on the foundation 7 through anchor bars 3 .

[0022] The bottom plate 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com