Nanometer compound anti-reflection film coating liquid for preparing solar energy photovoltaic glass and solar energy photovoltaic glass

A solar photovoltaic and nanocomposite technology, which is applied in the field of nanocomposite anti-reflection coating solution and solar photovoltaic glass, can solve the problems of difficult photoelectric conversion rate of solar cells, easily dirty and difficult to clean the surface of solar cell components, and promote the absorption of sunlight Energy, increase internal reflection effect, strong self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Prepare a water-alcohol mixed solvent: Take 30kg of water and 70kg of methanol to make a water-alcohol mixed solvent.

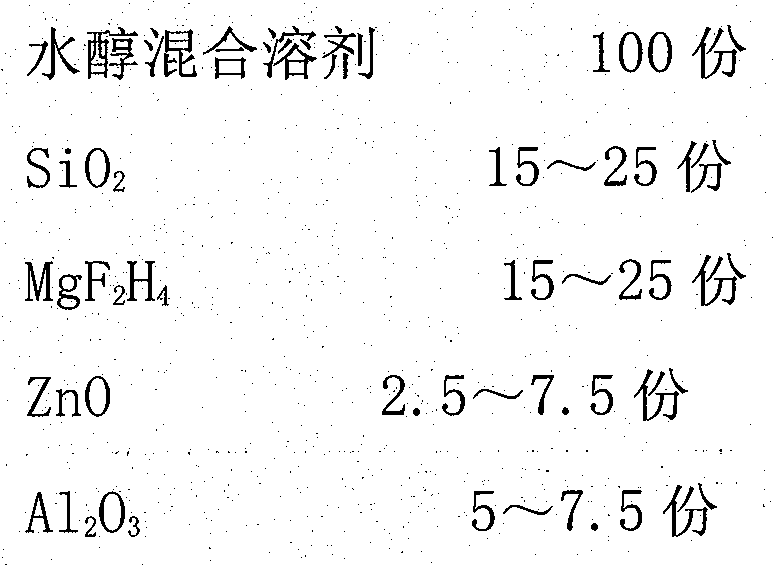

[0040] 2. Weigh SiO with an average particle size of 50-80nm 2 25kg, MgF 2 h 4 15kg, ZnO 5kg and Al 2 o 3 7.5 kg was dissolved in the above-mentioned water-alcohol mixed solvent to prepare coating slurry.

[0041] 3. Spray the above coating slurry on the glass substrate, bake at 300°C-400°C for 30 minutes to make the coating thickness 300-400nm, and obtain solar photovoltaic AR glass.

[0042] 4. After testing, the transmittance of solar photovoltaic glass increases by 3-4%.

Embodiment 2

[0044] 1. Prepare a water-alcohol mixed solvent: Take 50kg of water and 50kg of ethanol to make a water-alcohol mixed solvent.

[0045] 2. Weigh SiO with an average particle size of 50-80nm 2 20kg, MgF 2 h 4 20kg, ZnO2.5kg and Al 2 o 3 5. kgg is dissolved in the above-mentioned water-alcohol mixed solvent to prepare a coating slurry.

[0046]3. Pull the above-mentioned coating paste on the glass substrate, bake at 300°C-400°C for 30 minutes, make the coating thickness 300-400nm, and obtain solar photovoltaic AR glass.

[0047] 4. After testing, the transmittance of solar photovoltaic glass increases by 3-4%.

Embodiment 3

[0049] 1. Prepare a water-alcohol mixed solvent: Take 40kg of water and 60kg of propanol to make a water-alcohol mixed solvent.

[0050] 2. Weigh 15kg of SiO2 with an average particle size of 50-80nm, MgF 2 h 4 25kg, ZnO 7.5kg and Al 2 o 3 5 kg was dissolved in the above-mentioned water-alcohol mixed solvent to prepare coating slurry.

[0051] 3. Spin-coat or flow-coat the above-mentioned coating slurry on the glass substrate and bake at 300°C-400°C for 30 minutes to make the coating thickness 300-400nm to obtain solar photovoltaic AR glass.

[0052] 4. After testing, the transmittance of solar photovoltaic glass increases by 3-4%.

[0053] The advantage of the solar photovoltaic glass of the present invention is that there is a wide transmittance from 250-7000nm, especially when the visible light is at a wavelength of 250nm-7000nm, the film layer has an optical density (thickness) n*d that is 1 / 2 or 1 / 4 wavelength. And the film layer is firm, stable, high light transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com