Sealing up screw

A technology of water-stop screw and water-stop sheet, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, and construction. High cost and other issues, to achieve the effect of convenient disassembly and installation, labor saving, shortening construction hours, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

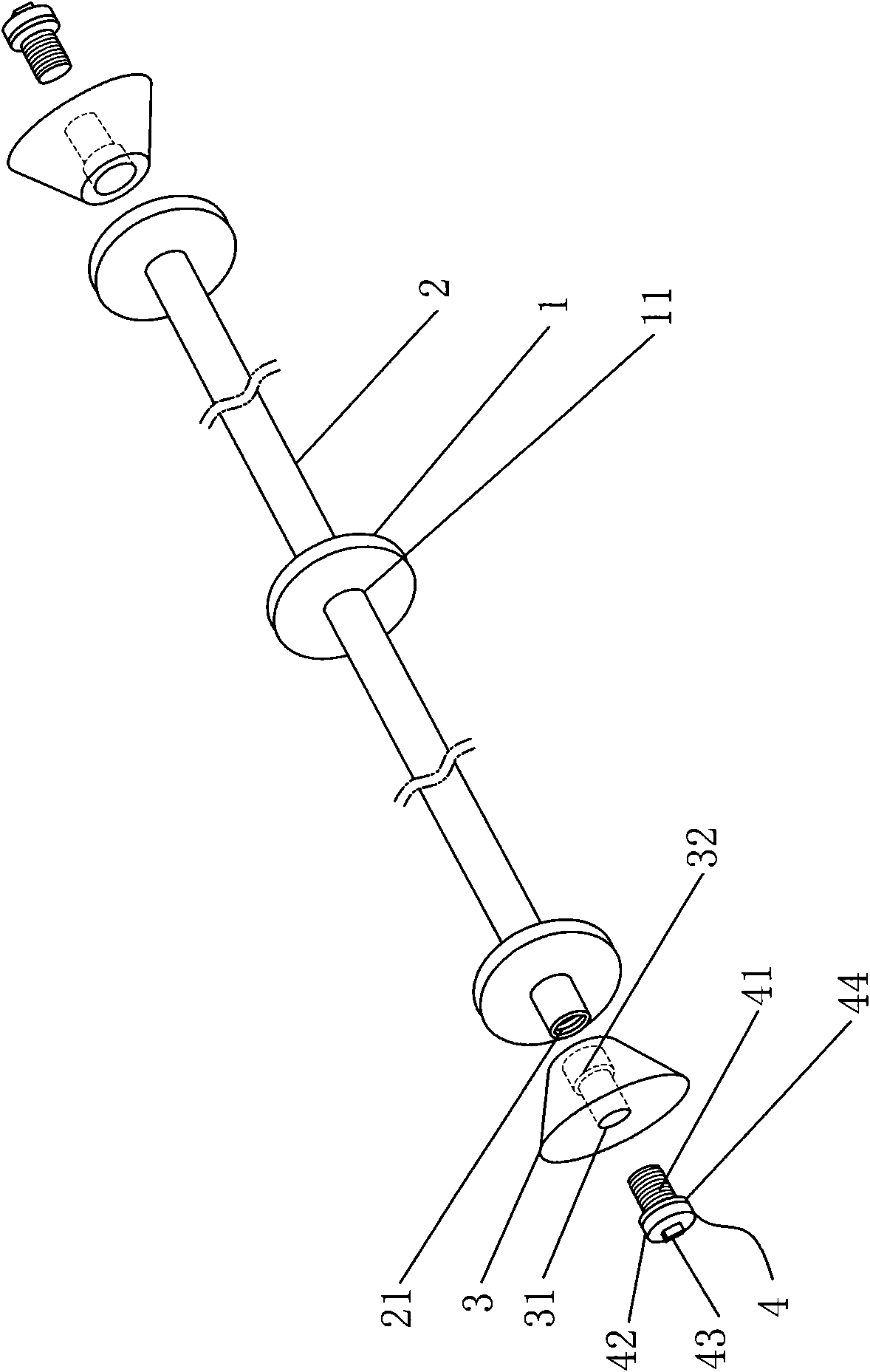

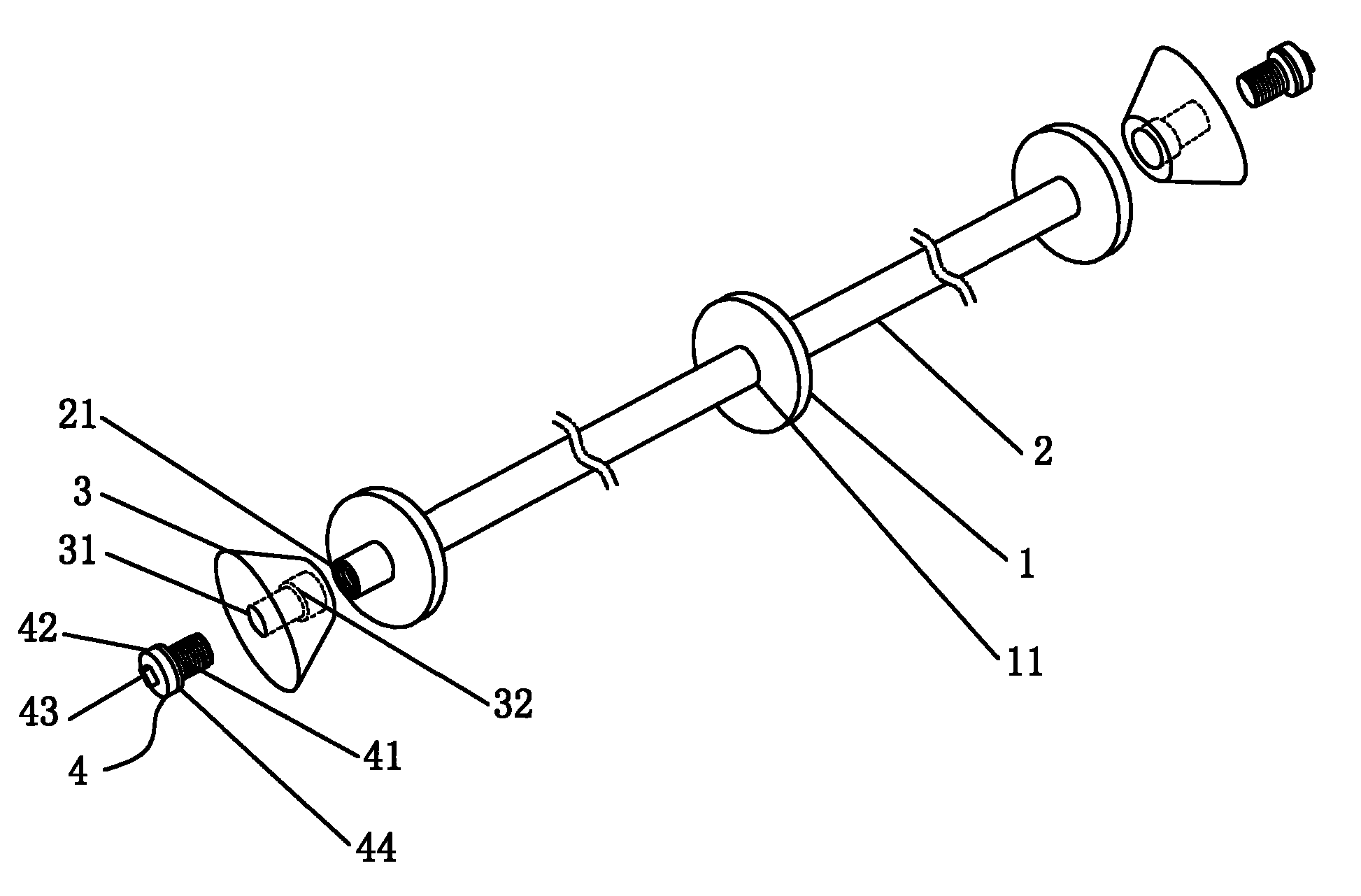

[0017] Such as figure 1 As shown, a water-stop screw includes three water-stop sheets 1 with holes 11, a casing 2, and three water-stop sheets 1 are respectively tightly connected to the two ends and the central end of the casing 2, and the water-stop Both the piece 1 and the casing 2 are sealed and connected. When made of metal, it is sealed and welded. When it is made of plastic, it can be processed in one piece. This structure also includes a small axial hole at one end. 31 and the other end are provided with an axial large hole 32 and communicated with the sleeve 3, and one end is provided with a plug 4 with an external thread 41, and both ends of the casing 2 are provided with an internal thread that matches the external thread 41 of the plug. 21. The large axial hole 32 in the sleeve 3 fits over both ends of the sleeve 2 and the end surface of the sleeve 3 is in close contact with the water-stop sheet 1 . The shape of the sleeve 3 is cylindrical or truncated, preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com