Card direct plug-in type lock core

An in-line, card-type technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

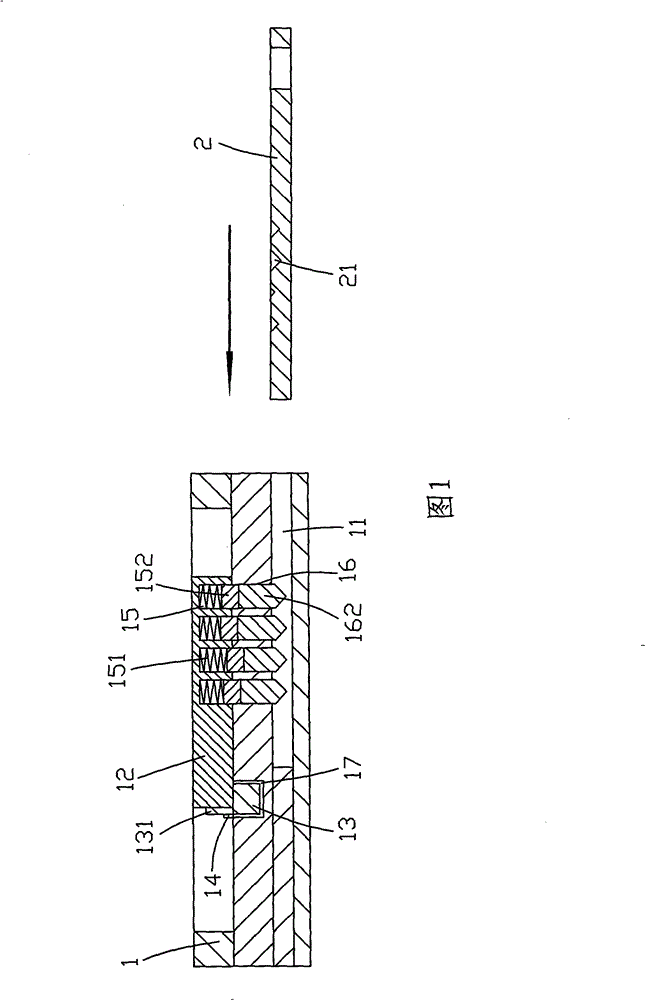

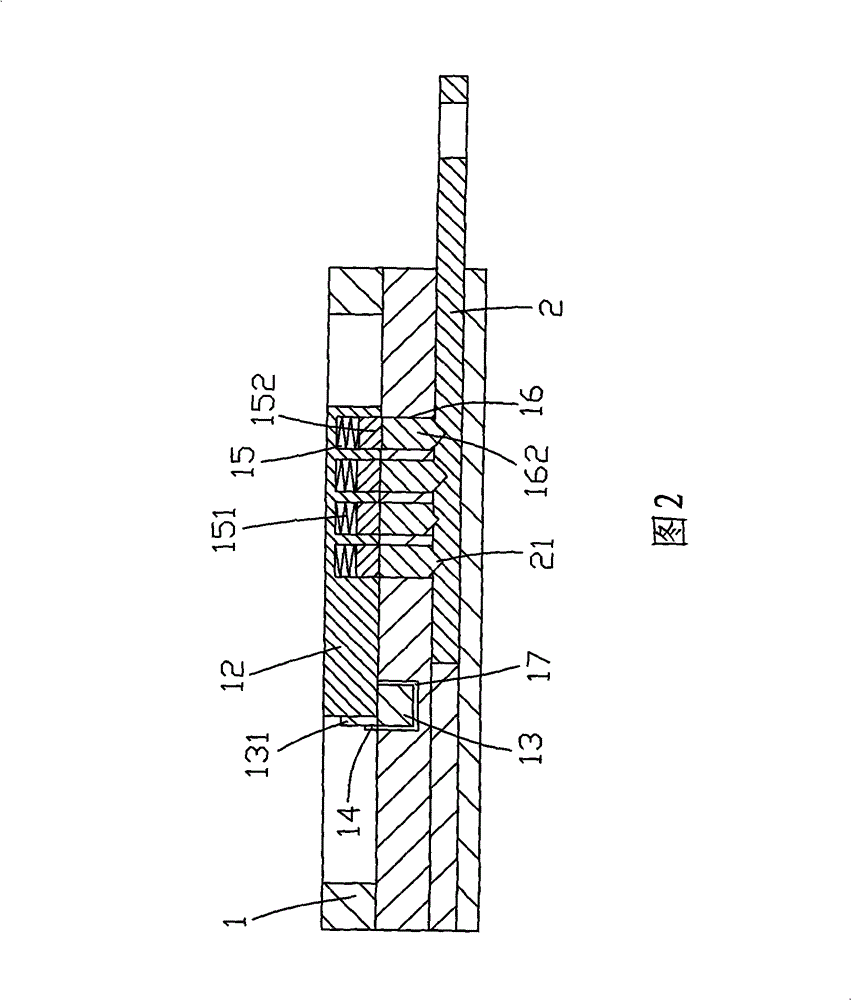

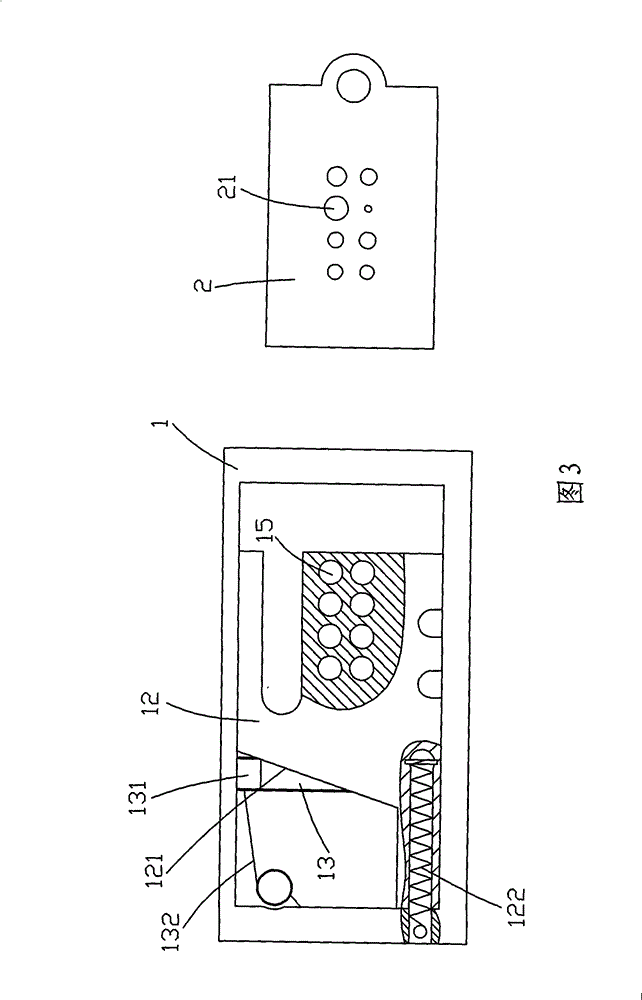

[0021] refer to Figure 1 to Figure 3 According to the card plug-in type lock cylinder provided by the present invention, it includes a lock cylinder body 1 and a key 2, the key 2 adopts a card structure, and a key slot 11 is opened on one side of the lock cylinder body 1 . A lock plate 12 and a top block 13 are slidably arranged in the lock core body 1. One end of the lock plate 12 is provided with an inclined surface 121, and the top block 13 is abutted against the inclined surface 121. The lock core body 1 is also provided with a top block 13 for connecting with the outside world. The opening 14 of the door lock, when the lock core is installed on the door lock for use, the top block 13 will abut against the unlocking mechanism of the door lock from the opening. On the lock plate 12 and the lock core body 1, there are respectively some upper marble holes 15 and lower marble holes 16, the upper and lower marble holes 15, 16 correspond to each other and communicate with the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com