Engine assembly with valve seat vent passages and method of forming

A technology of engine and valve seat, applied in the direction of engine components, combustion engines, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Examples of the invention will now be described more fully with reference to the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses.

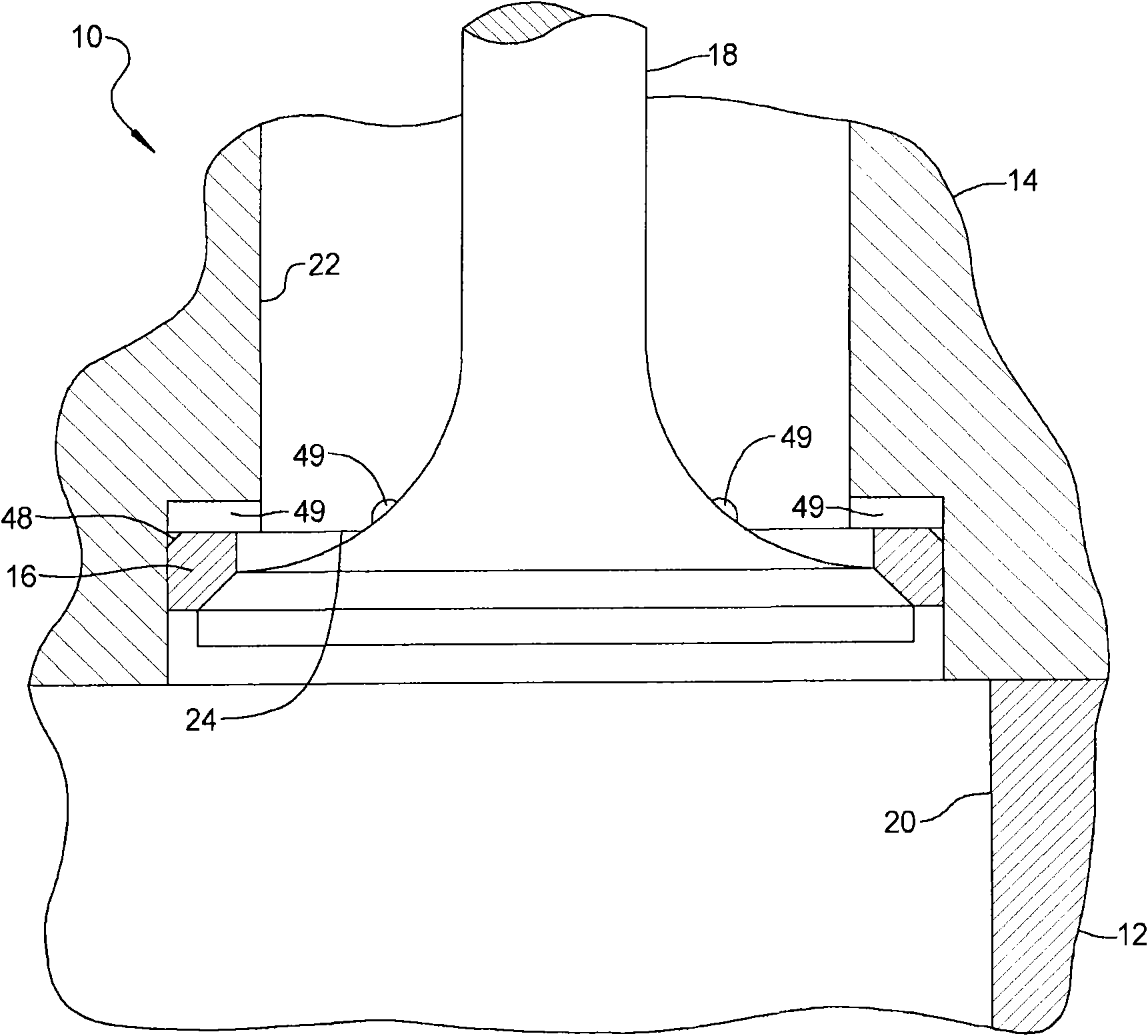

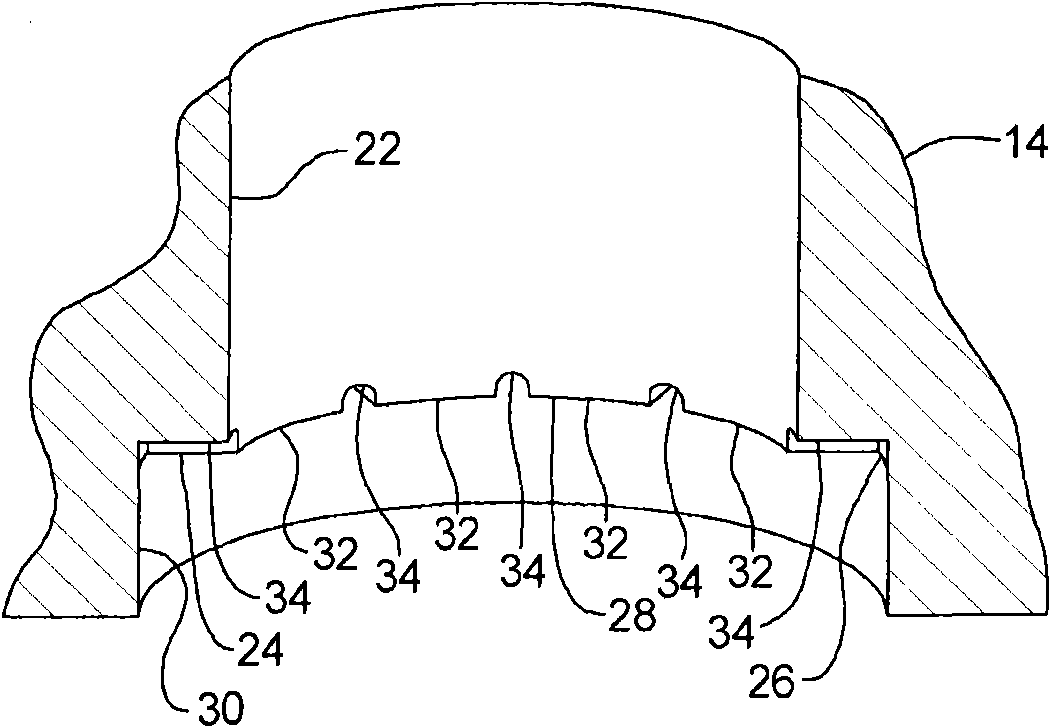

[0044] refer to Figure 1-4 , the engine assembly 10 may include an engine block 12 , a cylinder head 14 , a valve seat insert 16 and a valve 18 . The engine block 12 may define a cylinder bore 20 . Cylinder head 14 may be secured to engine block 12 and may define intake ports 22 and valve seats 24 .

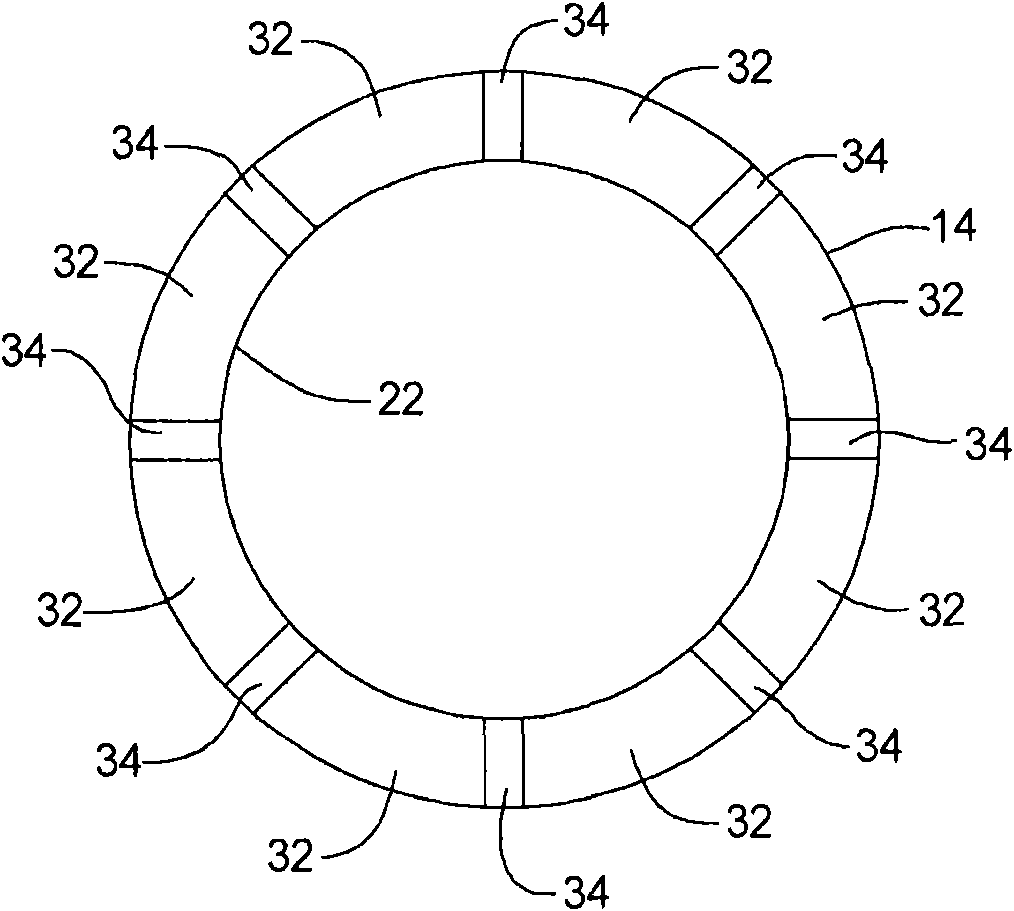

[0045] The valve seat 24 may be defined as an outlet of the intake port 22 and may include a stepped region 26 . The stepped region 26 may include an axial end surface 28 , an inner radial surface 30 , a raised portion 32 and a recessed portion 34 . The cylinder head features discussed above may be integrally formed as a single casting. Alternatively, the raised portion 32 and the recessed portion 34 may be formed in the cylinder head 14 af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com