Energy-saving single-screw compressor

A single-screw compressor and screw technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as reduced compressor efficiency, increased compressor discharge leakage, and increased compressor exhaust loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

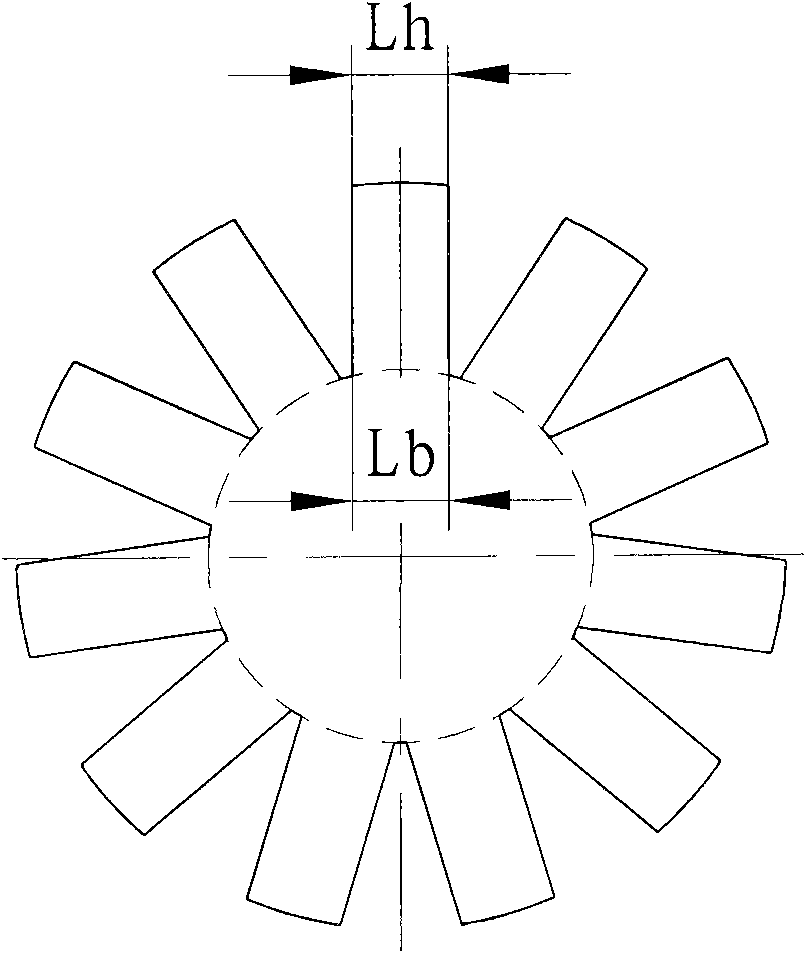

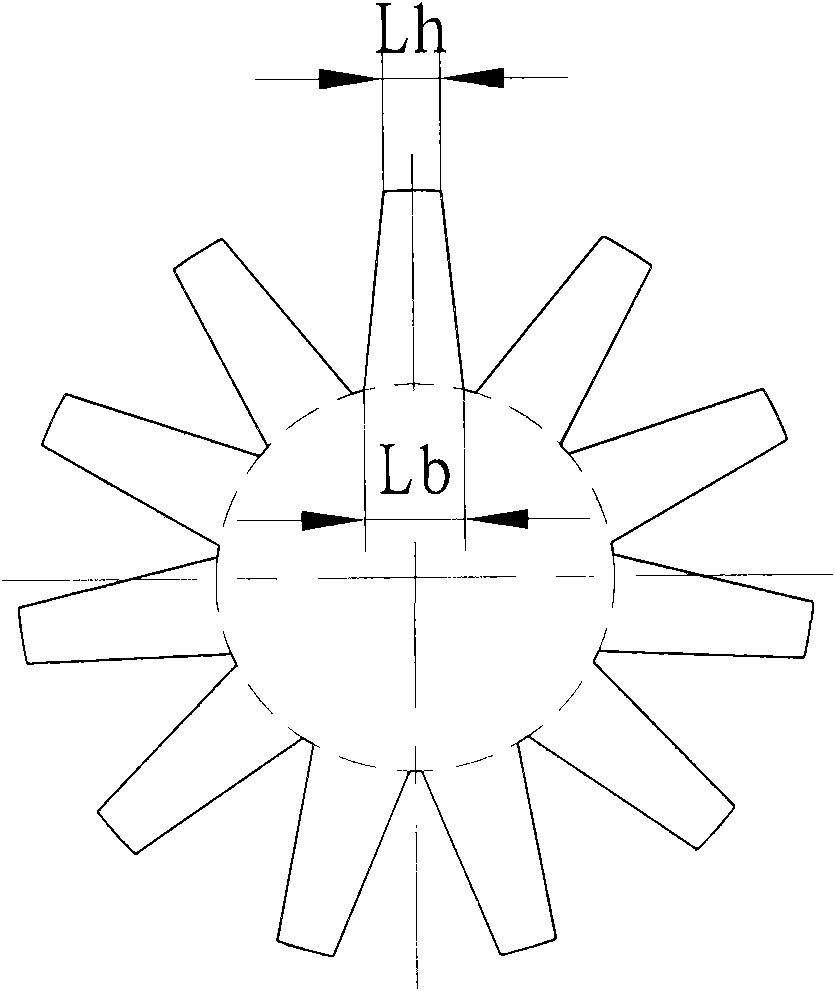

[0018] figure 1 and figure 2 They are the schematic diagrams of the straight tooth star wheel and the bevel tooth star wheel of the existing single-screw compressor respectively. In order to fully expand the tooth area of the star wheel teeth, the space between the teeth of the existing star wheel at the tooth bottom has been compressed to the minimum limit. Therefore, there is no difference between the star wheel of the single screw compressor of the present invention and the existing star wheel at the tooth bottom.

[0019] see figure 1 and figure 2 As shown, from the bottom of the tooth to the top of the tooth, the tooth width of the existing star wheel remains unchanged or the tooth width gradually narrows, that is, the width L of the tooth top of the working tooth of the existing star wheel h Less than or equal to tooth bottom width L b .

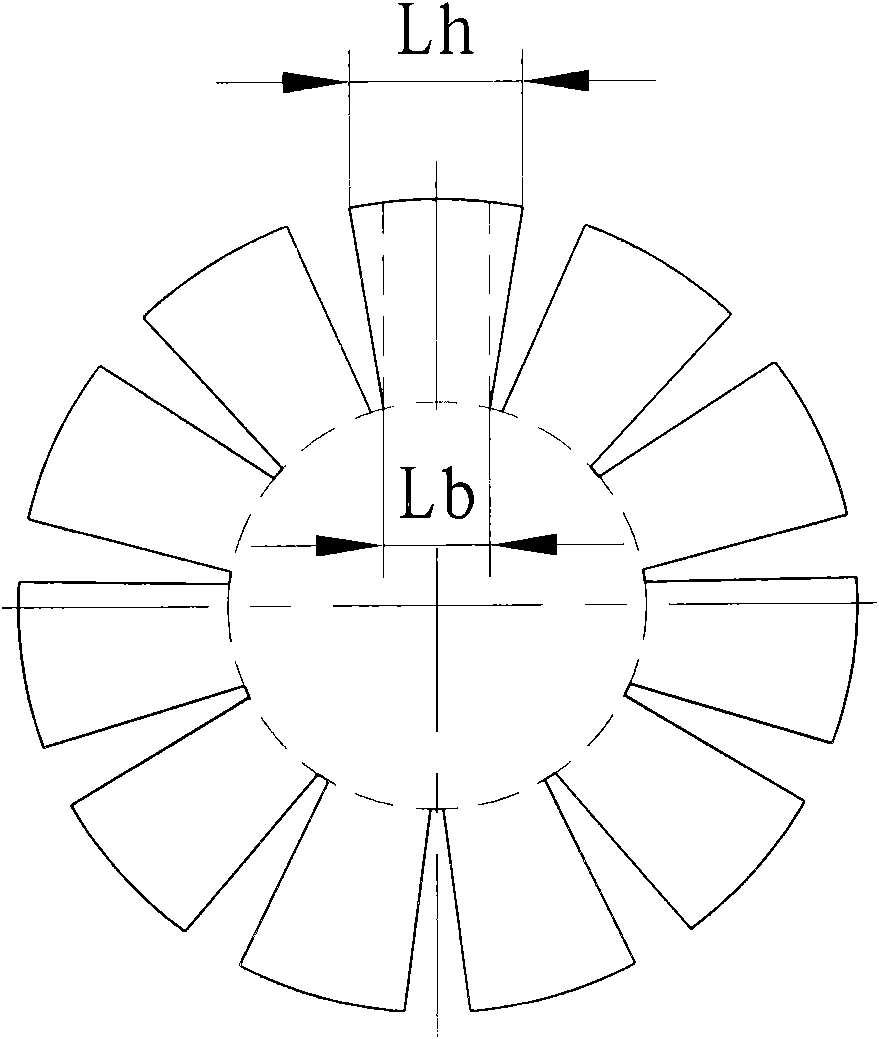

[0020] The anti-bevel tooth star wheel structure of the single-screw compressor proposed by the present invention is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com