Pressure-limiting stop valve

A shut-off valve and pressure-limiting technology, applied in the field of pressure-limiting shut-off valves, can solve the problems of high water pressure of source water, hidden danger of pure water machine system, and increase of the cost of pure water machine system, so as to achieve easy installation and application and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

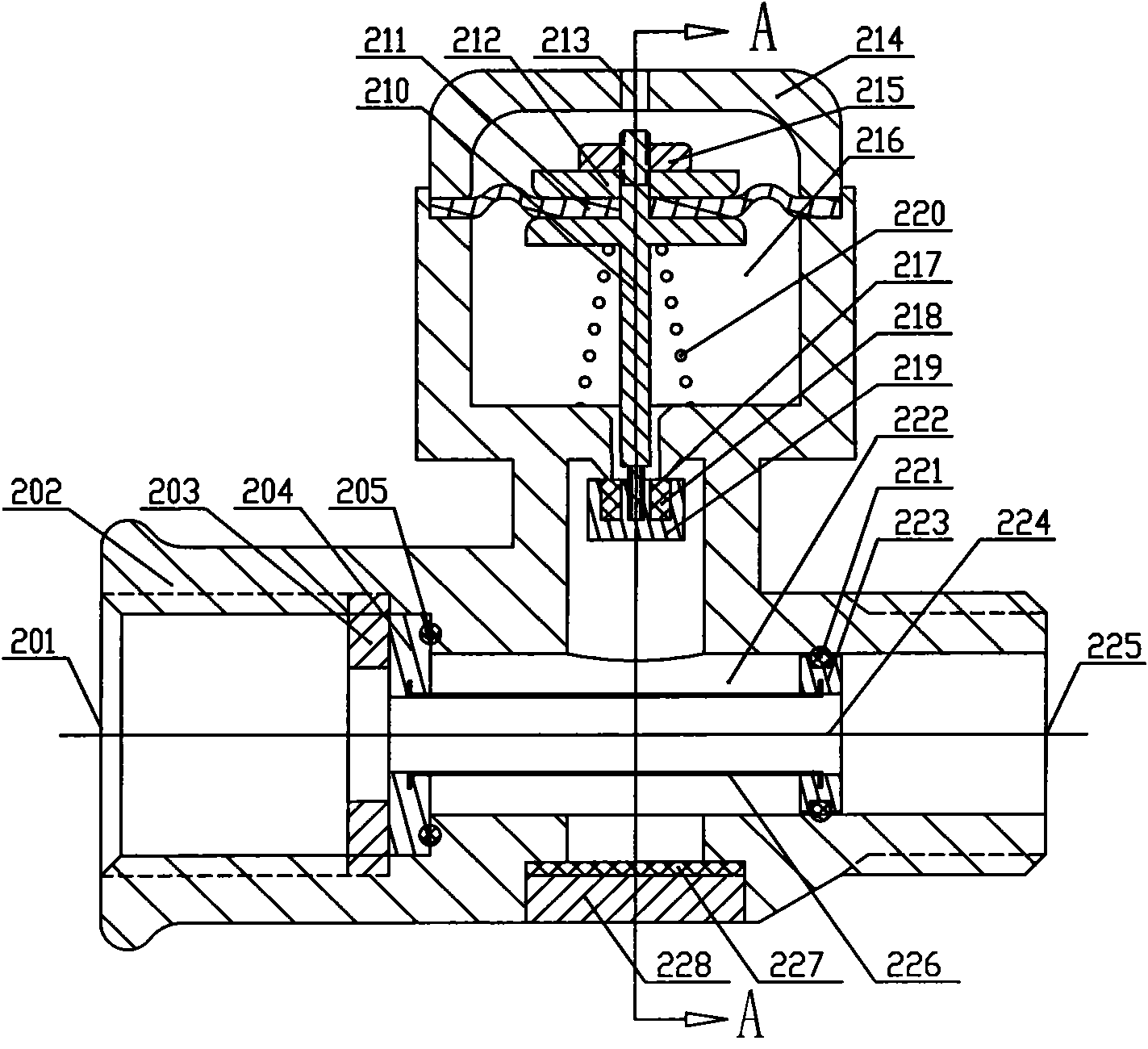

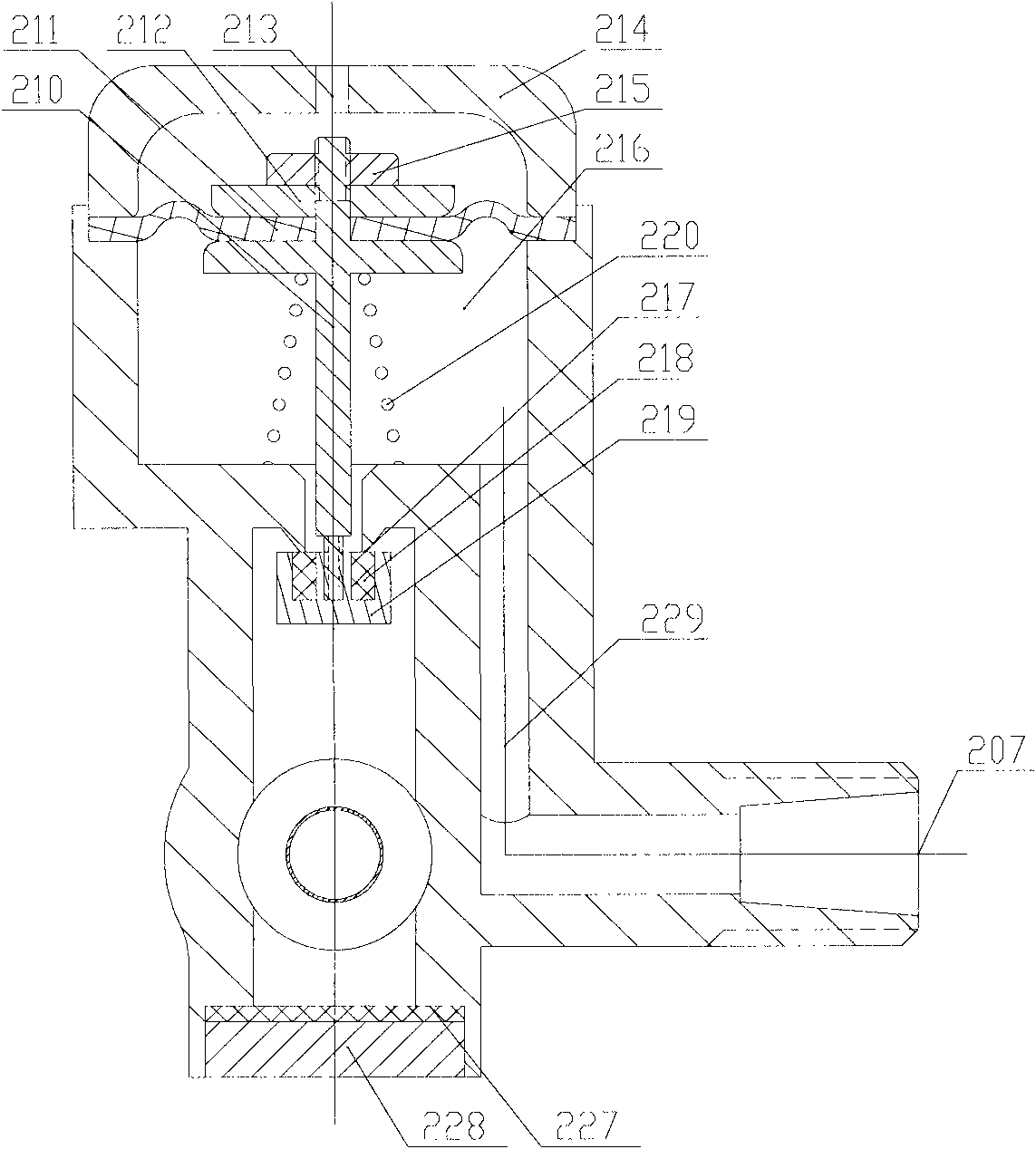

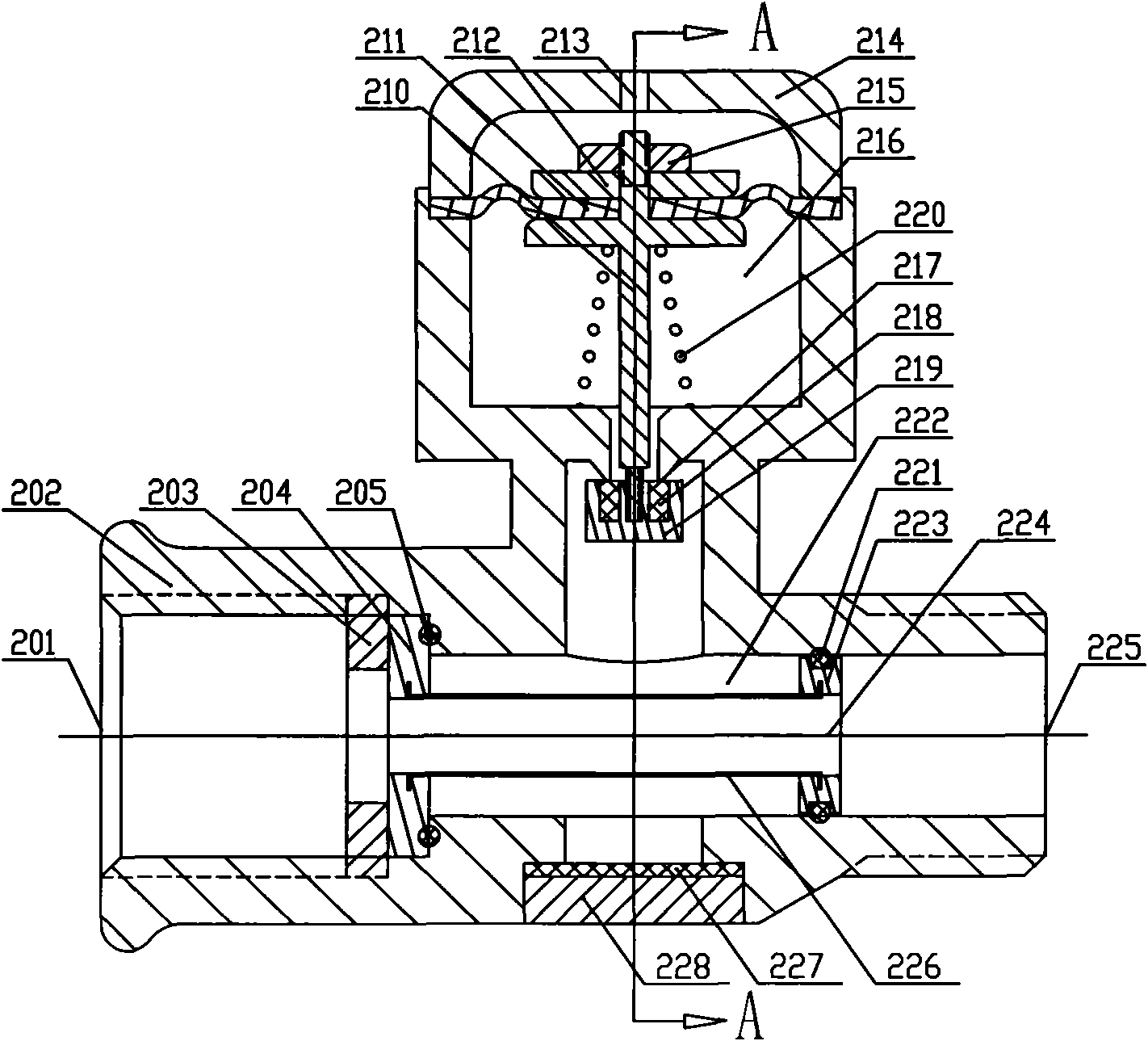

[0013] See Figure 1 to Figure 2 As shown, the pressure-limiting cut-off valve of the present invention includes a base 202. The base 202 has a source water inlet 225, a source water outlet 201, and a water purifier interface 207 that are connected to each other. The inlet 225 and the source water outlet 201 are connected with a pressure-limiting component; the source water inlet 225 and the source water outlet 201 are connected with a filter screen 226 with a hollow flow channel. The two ends of the filter screen 226 are respectively The rear ring seal 205 of the filter screen and the front ring seal ring 221 of the filter screen are sealed and fixed to the inner wall of the base 202; the filter screen 226 is cylindrical, and the hollow flow channel in it forms the source water channel 224. The watershed constitutes a filtered water cavity 222, the inlet end of the pressure limiting component is communicated with the filtered water cavity 222, and the outlet end of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com