Measuring method for on-site detection of thermal resistance of enclosing structure

An enclosure structure, on-site detection technology, applied in the direction of material thermal development, material thermal conductivity, etc., can solve problems such as thermal resistance detection error, and achieve the effect of reducing influence and error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

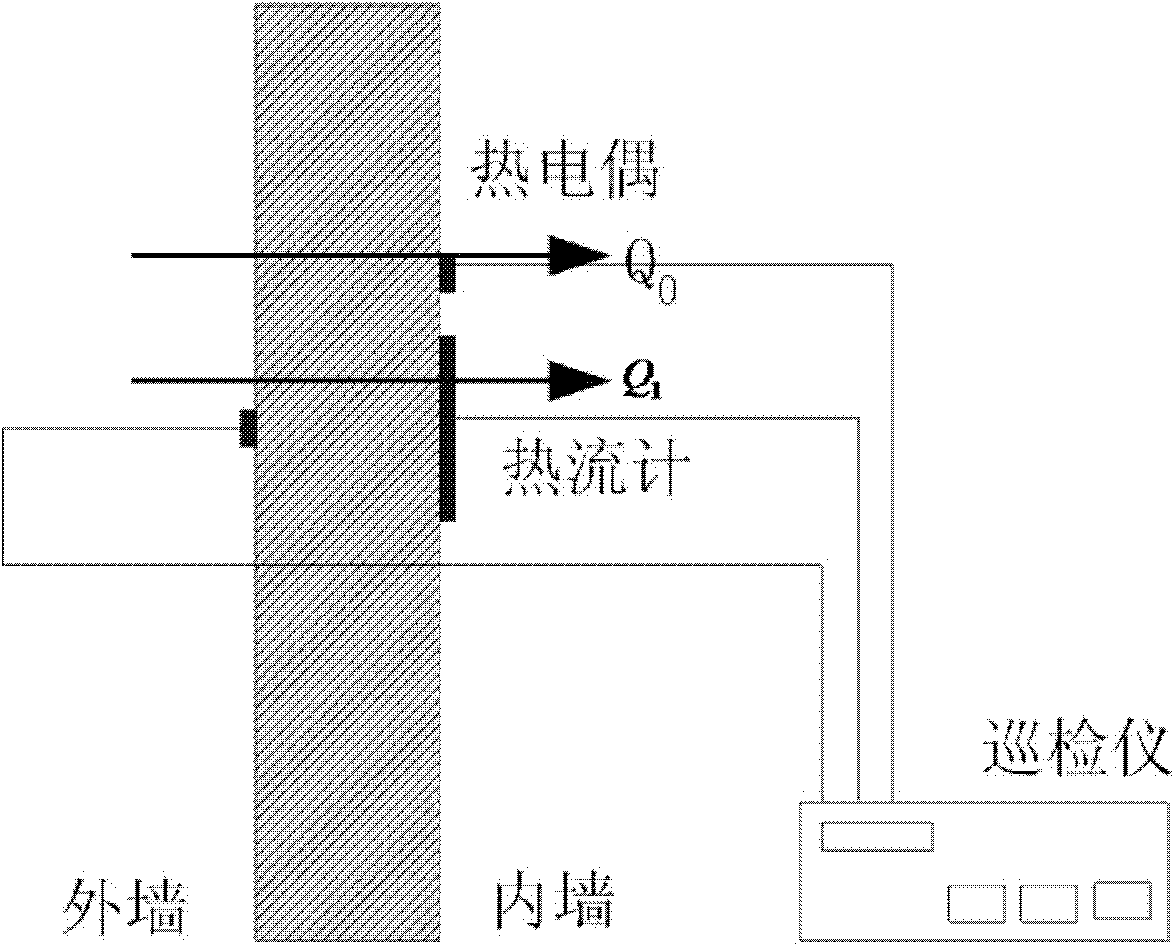

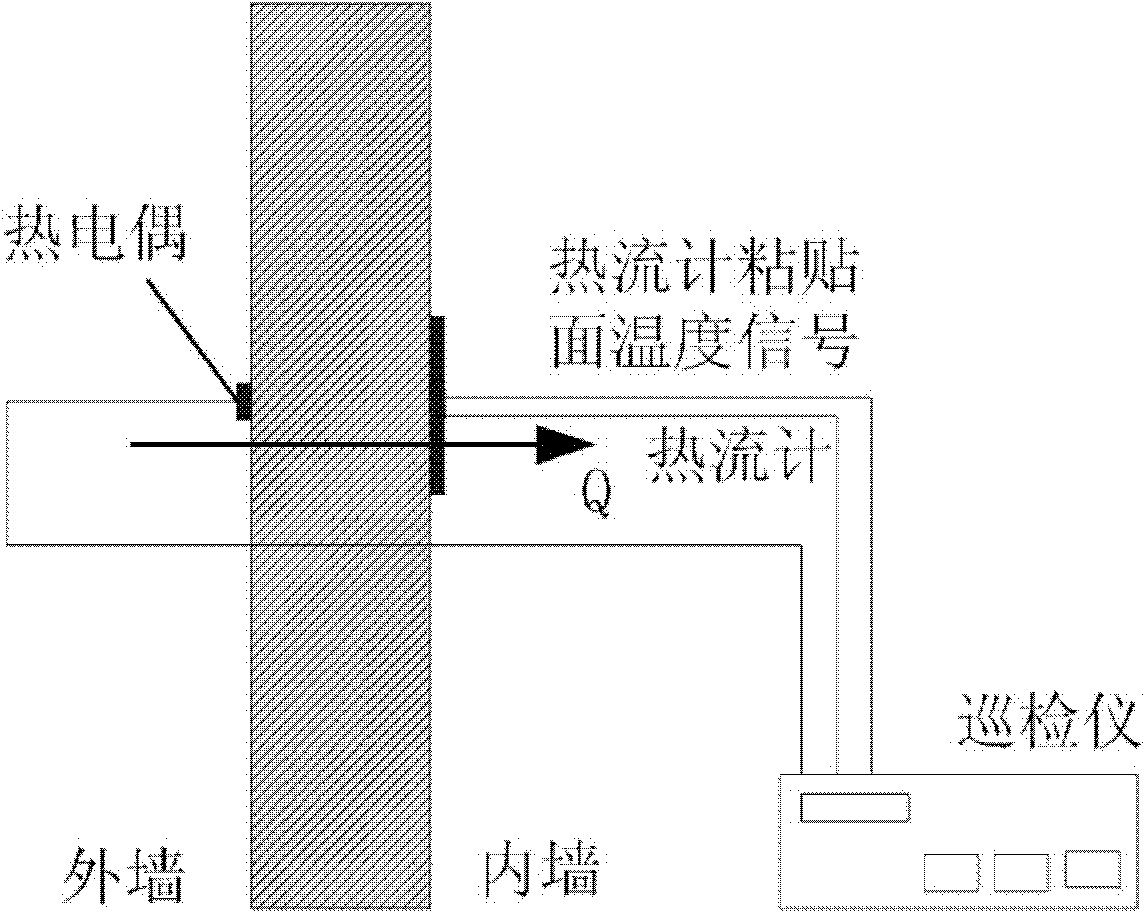

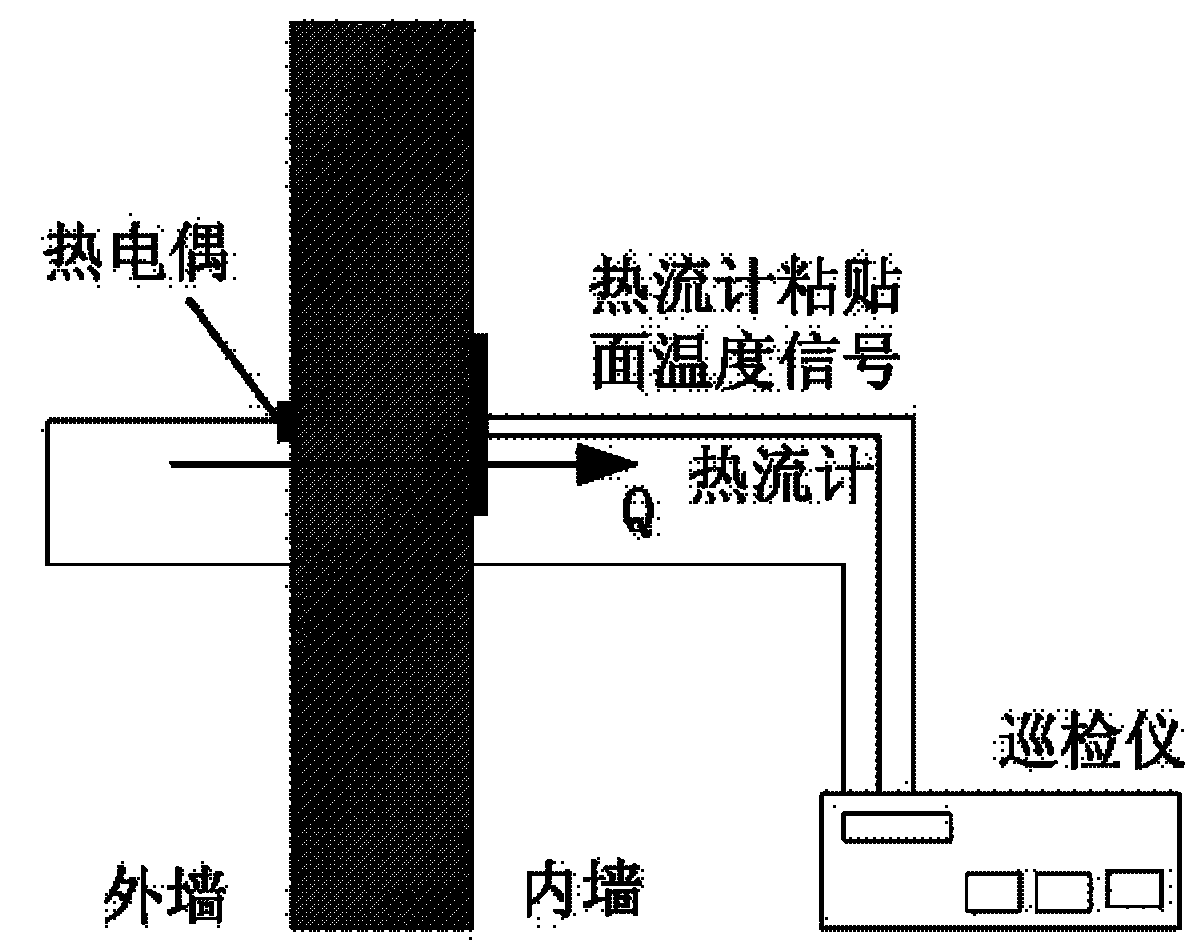

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] see figure 2 , in view of the error produced in the process of field testing of the existing heat flow meter method, the present invention will use the temperature of the heat flow meter and the wall pasting surface to be extracted during the test, that is, the temperature signal of the heat flow meter pasting surface to replace the original temperature of the wall surface near the heat flow meter, so that The measured heat flow corresponds to the temperature difference, so in the case of one-dimensional heat transfer at the test site, the calculation of thermal resistance will not be affected. The calculation formula in steady state is: R=ΔT / Q, ΔT is the temperature of the inner surface The temperature difference with the outer surface, Q is the heat flow of the heat flow meter reaction.

[0014] During installation, install the thermocouples on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com