Covered wire cold connector

A technology of leather wires and connecting tubes, which is applied in the coupling of optical waveguides, etc., can solve the problems of maintenance of insertion loss, clean drainage, and no consideration of air, etc., and achieve simple structure, reduce loss value, and improve reliability and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

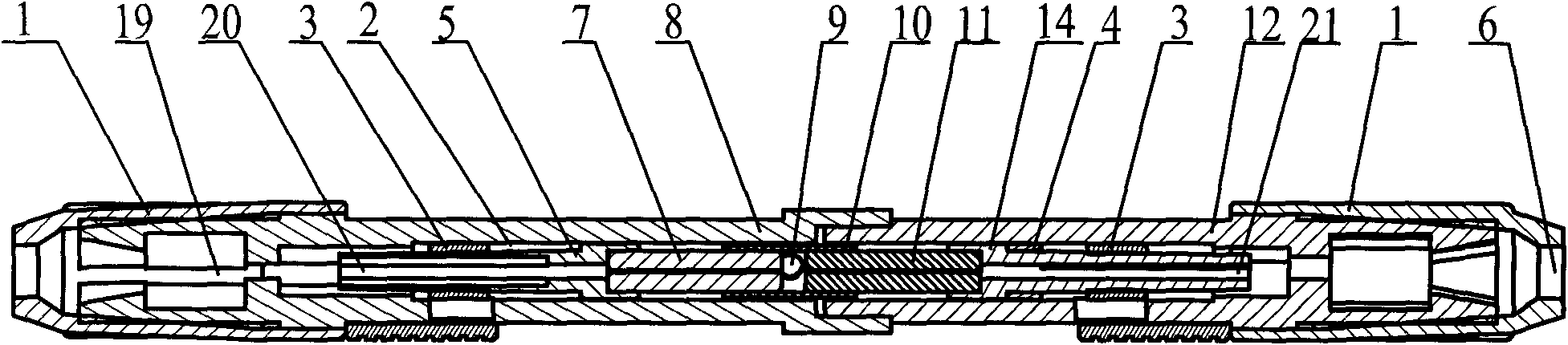

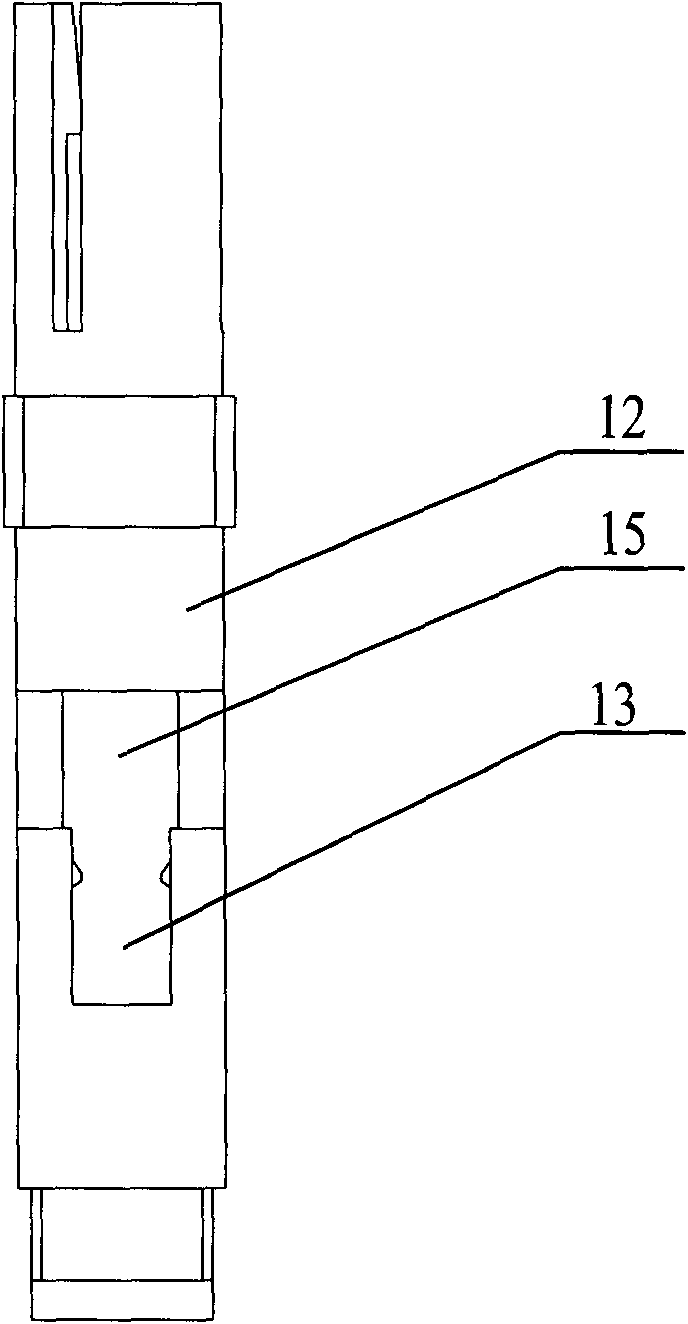

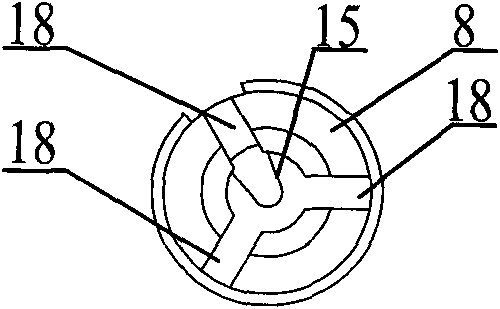

[0018] Such as Figure 1 to Figure 6 As shown: the present invention includes a boot 1, a crimping groove 2, a crimping twist 3, a ferrule pusher 4, a first ferrule tail handle 5, a connecting through hole 6, a first ferrule 7, and a first ferrule cavity 8. Vent hole 9, connecting pipe 10, second ferrule 11, second ferrule cavity 12, installation groove 13, second ferrule tail handle 14, positioning groove 15, crimping hole 16, connecting hole 17, The first dividing groove 18 , the second dividing groove 19 , the first slot 20 and the second slot 21 .

[0019] Such as figure 1 As shown: one end of the first ferrule cavity 8 is provided with a groove; one end of the second ferrule cavity 12 is embedded in the groove of the first ferrule cavity 8, and is connected with the first ferrule cavity The cavity 8 is tightly connected; the first ferrule cavity 8 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com