Touch display device and touch device

A technology of a touch display device and a touch device, which is applied to instruments, electrical digital data processing, and the input/output process of data processing. The effect of measuring sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

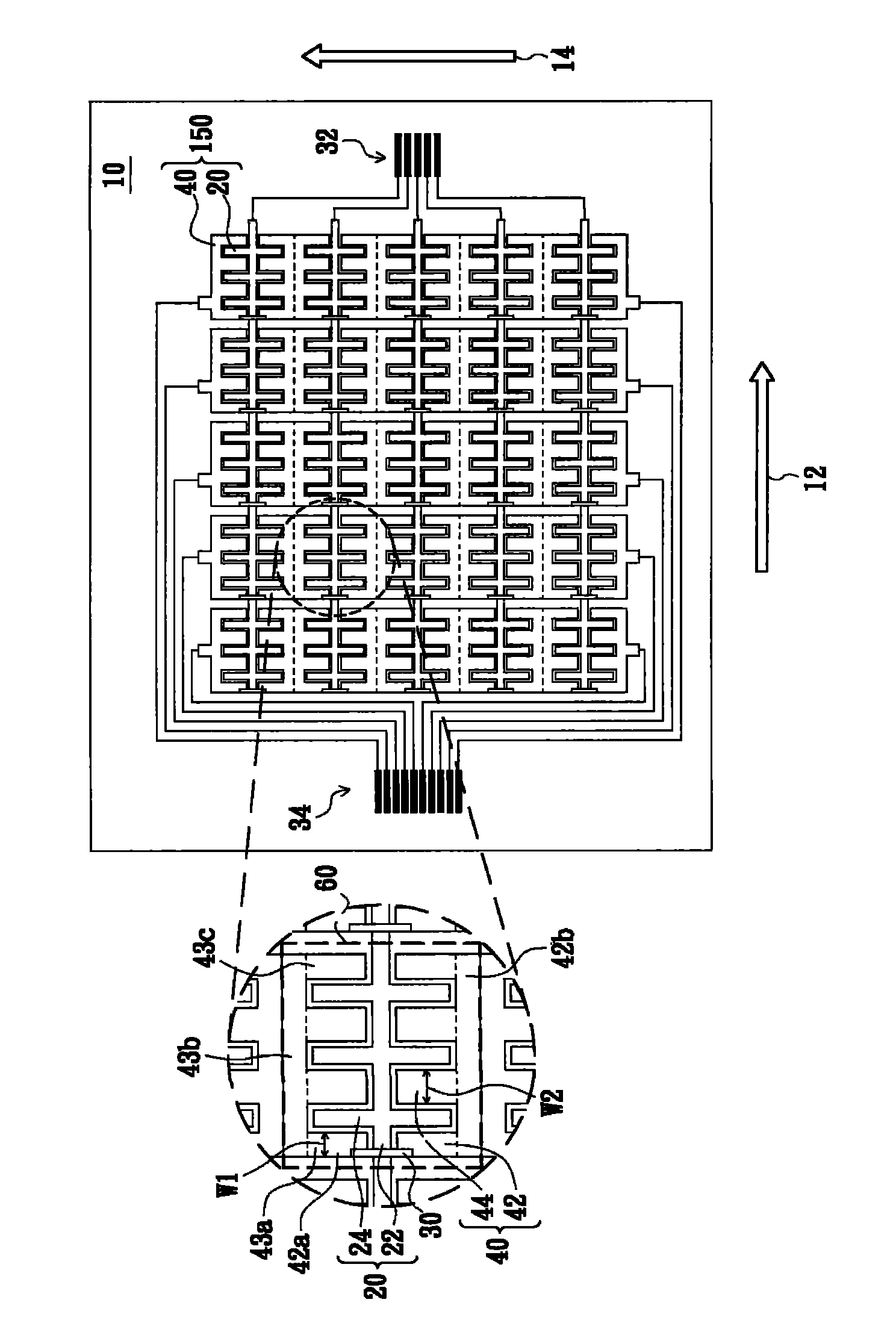

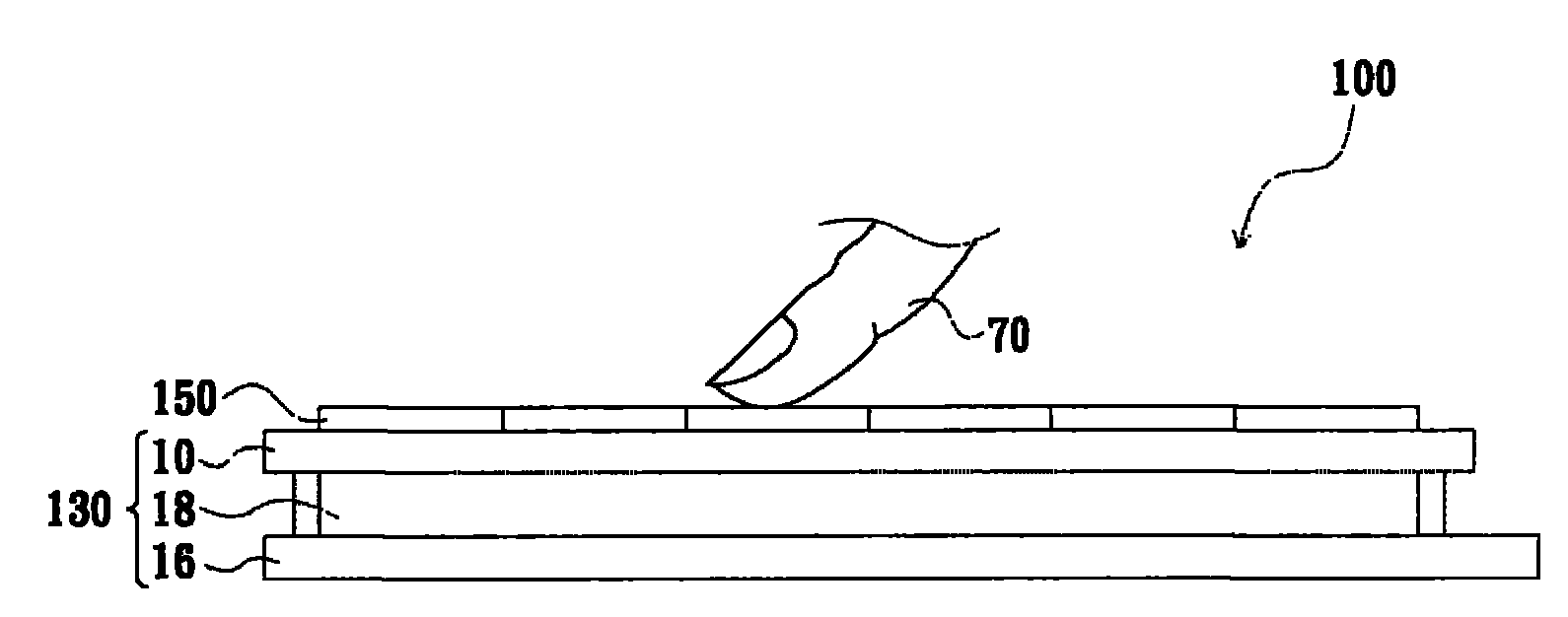

[0039] Such as figure 1As shown, the touch sensing element 150 is disposed on the substrate 10 , including the sensing electrodes 20 , the driving electrodes 40 , the first connection line 32 of the first circuit, the second connection line 34 of the second circuit and the bridge line 30 . The touch sensing element 150 can be a capacitive touch device, such as a projected capacitive touch matrix structure, especially a mutual type projected capacitive touch matrix structure. The sensing electrodes 20 and the driving electrodes 40 are composed of two different sets of electrodes, which are respectively connected to the first connection line 32 of the first circuit and the second connection line 34 of the second circuit. Wherein, each sensing electrode 20 can be arranged parallelly on the substrate 10 substantially along the first direction 12 , and each driving electrode 40 can be arranged parallelly on the substrate 10 substantially along the second direction 14 . The first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com