Single-carrier-roller belt type conveyer

A technology for belt conveyors and rollers, which is applied in the direction of conveyor objects, rollers, transportation and packaging, etc., and can solve problems such as no self-cleaning effect of the tail roller, deviation of the conveyor belt, and failure of the equipment to reach full closure. Achieve the effect of solving the problem of tail accumulation and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

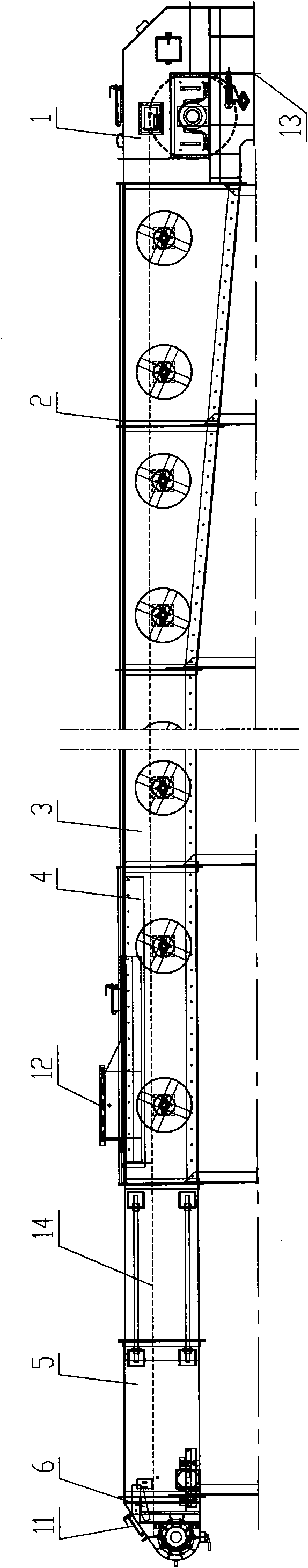

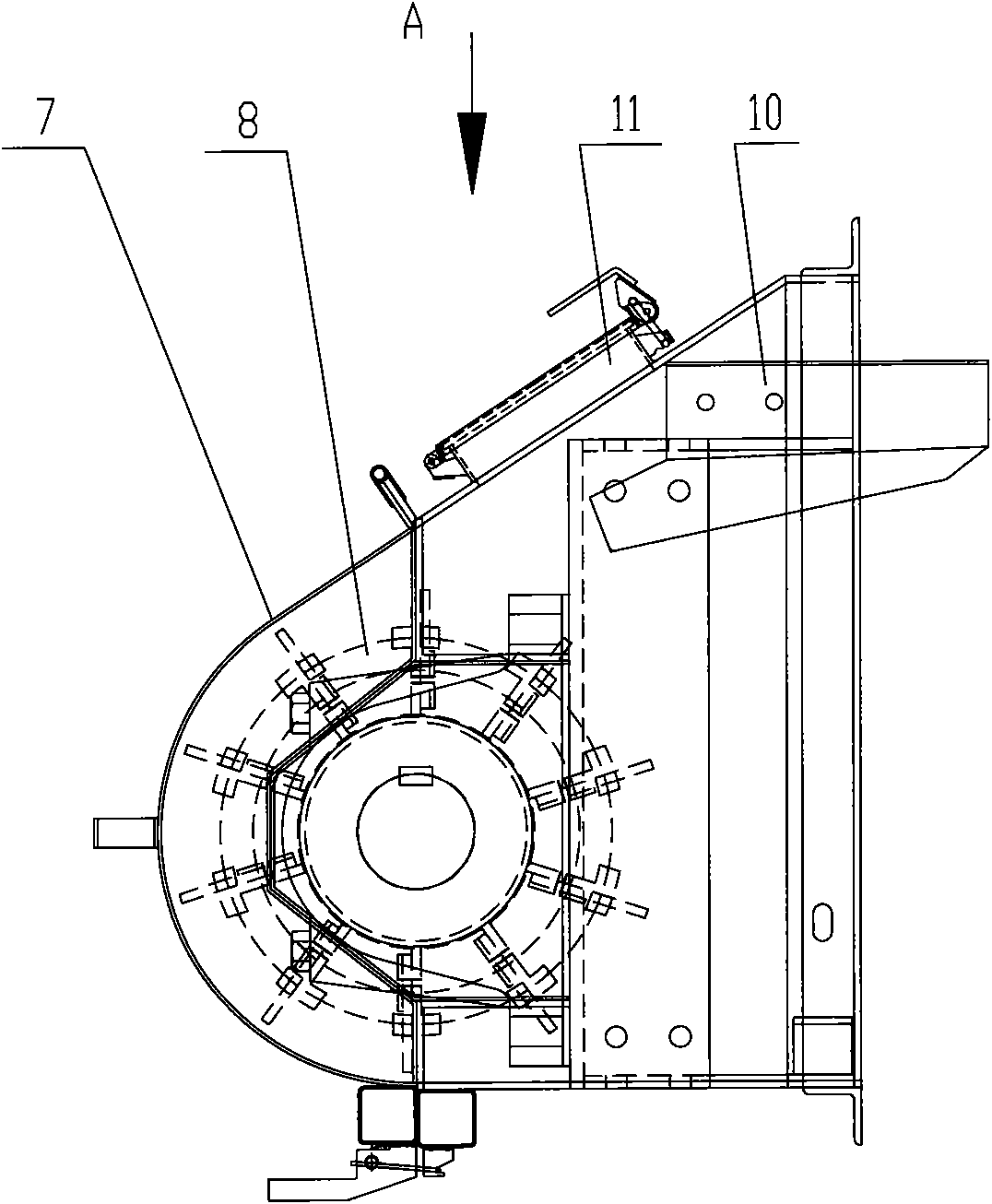

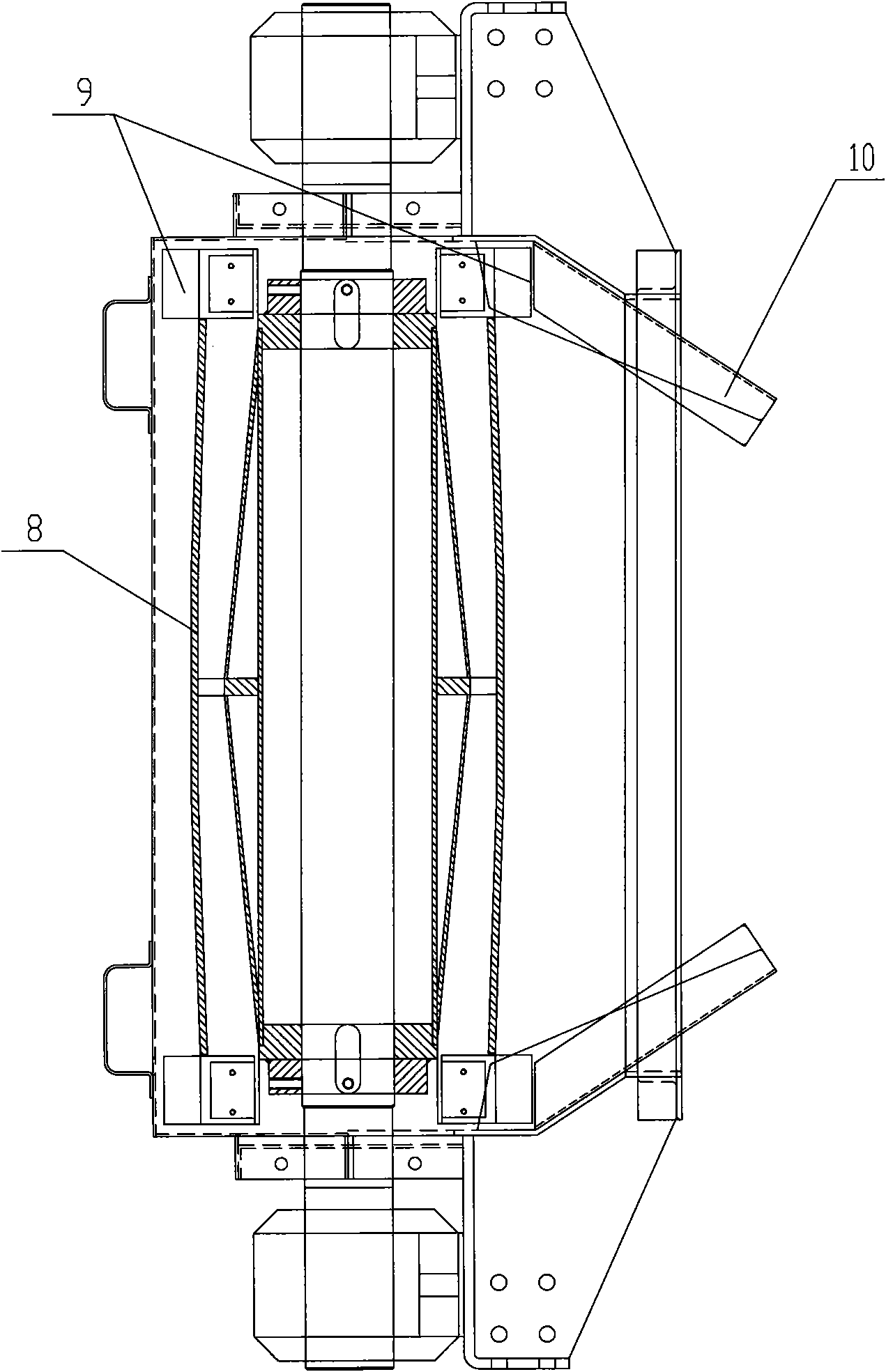

[0013] Such as Figure 1~3 A kind of single idler belt conveyor shown, it comprises: head section 1, middle section 2, feed section 3, transition section 4, tension section 5 and tail section 6, the casing of described tail section 6 7 is a circular structure, the tail section 6 is provided with a tail roller 8, the two sides of the tail roller 8 are provided with a unique wind blade bucket type return device 9, and the tail section 6 is provided with a tail roller on the upper left side. Roller baffle 10. When working, the material falls on the conveyor belt 14 from the feed port 12, and is sent to the discharge port 13 through the conveyor belt 14. Because the material has a certain viscosity, the material at the lower part will adhere to the conveyor belt 14 due to gravity and other reasons. Unable to transport out, when the conveyor belt 14 passes through the tail section 6, the unique wind blade bucket type return device 9 is provided on both sides of the tail roller 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com