Rolled reverse osmosis membrane element

A technology of reverse osmosis membrane and components, applied in the field of water purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

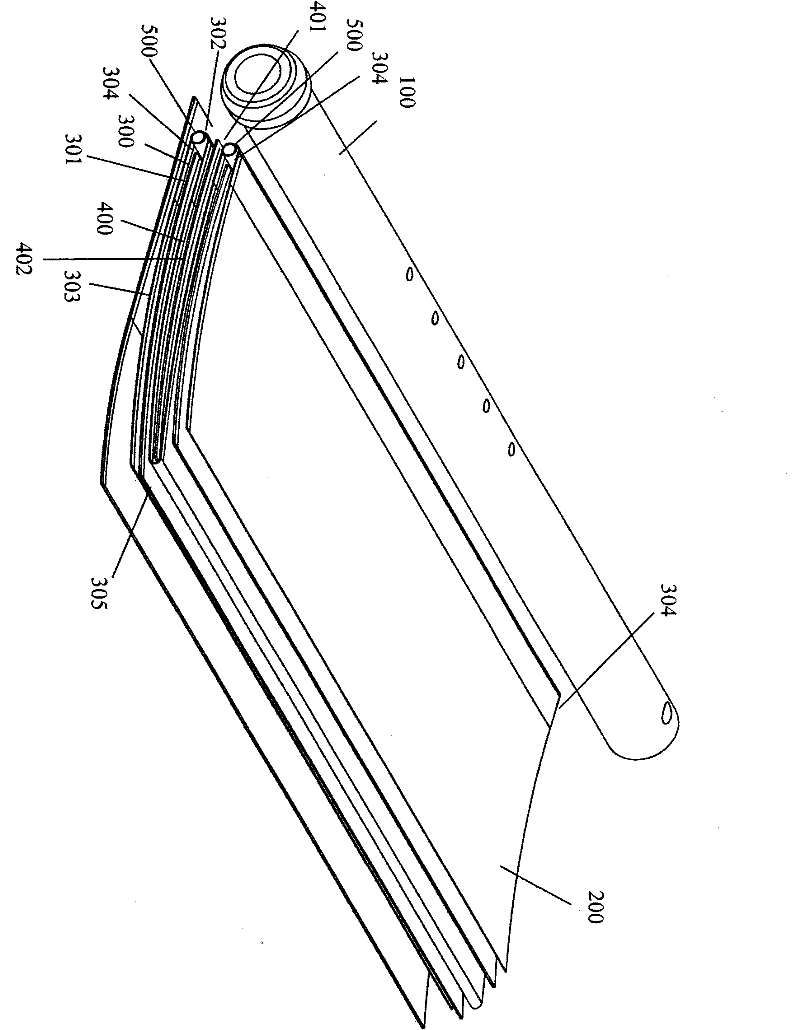

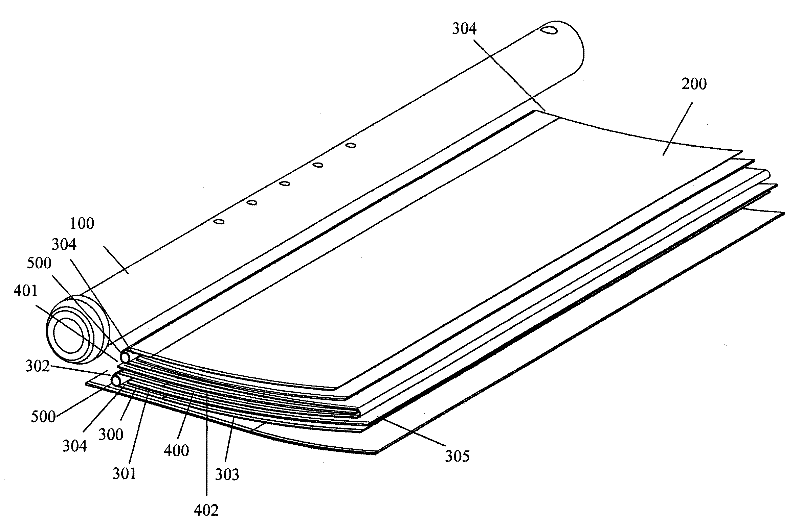

[0016] like figure 1 As shown, the roll-type reverse osmosis membrane element of the present invention is an improvement on the basis of the roll-type reverse osmosis membrane element with the application number 200910201739.8, including a central water production pipe 100, a reverse osmosis membrane 200 wound on the central water production pipe 100, The reverse osmosis membrane is folded to form a water inlet channel 300 and a water production channel 400. The water inlet channel 300 is provided with a water inlet diversion net 301, and the water production channel 400 only has a pure water outlet 401 facing the central water production pipe 100. A pure water diversion net 402 is provided in the produced water channel 400 . The parts of the two sides 303 adjacent to the folded edge 302 of the water inlet flow channel 300 that are far away from the central water production pipe 100 are closed and sealed so that the two sides 303 are close to the central water production pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com