Method for preparing nanometer nitro celluloses

A technology of nitrocellulose and nano-cellulose, which is applied in the field of preparation of nano-nitrocellulose, can solve the problems of poor stability of nitrocellulose, pollution of nitrocellulose production, complex post-treatment and reuse of waste acid, etc., and achieve shortening of nitration time, Effect of Stability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of nanocellulose suspension

[0024] Cotton cellulose powder was ultrasonically pretreated in an ice bath for 15 minutes, filtered and dried for later use.

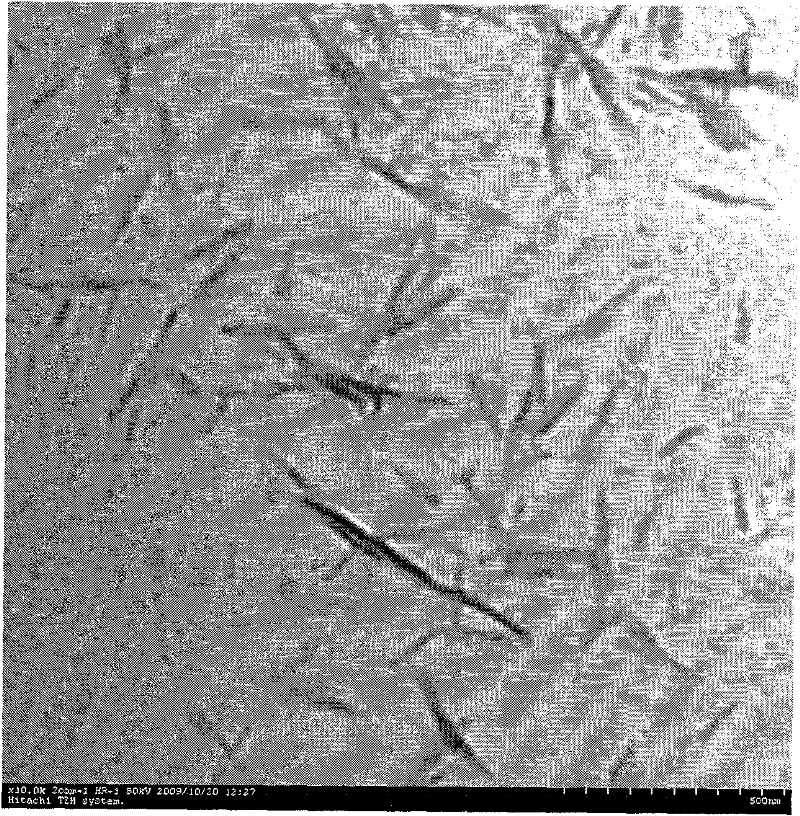

[0025] Immerse 0.5g of the above-mentioned cellulose powder accurately weighed in 8.75ml of sulfuric acid solution with a concentration of 64wt%, stir and react in a water bath at 45°C for 1h, then add 10 times the volume of deionized water to dilute the reaction solution; the diluted reaction The solution was centrifuged at 8000 rpm; the suspension was dialyzed in deionized water for 24 hours until the pH value was the same as that of the deionized water used. The molecular weight cut-off of the dialysis bag used is 8000-14000; finally, after ultrasonic dispersion with a power of 150w for 15 minutes, a stable suspension of nanocellulose whiskers is obtained, wherein the nanocellulose whiskers have a diameter of 20-30nm and a length of 150- 250nm. The morphology of the prepared nanocellulose whisk...

Embodiment 2

[0029] (1) Preparation of nanocellulose suspension

[0030] Cotton cellulose powder was ultrasonically pretreated in an ice bath for 15 minutes, filtered and dried for later use.

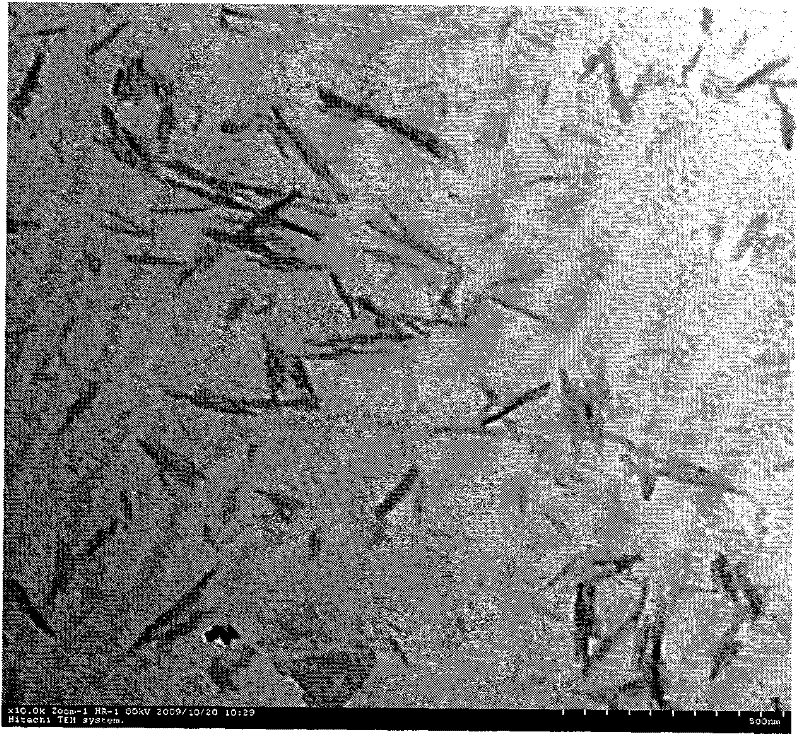

[0031] Immerse 0.5g of the above-mentioned cellulose powder accurately weighed in 25ml of sulfuric acid solution with a concentration of 64wt%, stir and react in a water bath at 60°C for 4h, then add 10 times the volume of deionized water to dilute the reaction solution; the diluted reaction solution Centrifuge at 8000 rpm; dialyze the suspension in deionized water for 24 hours until the pH is the same as that of the deionized water used. The molecular weight cut-off of the dialysis bag used is 8000-14000; finally, after ultrasonic dispersion with a power of 150w for 15 minutes, a stable nanocellulose whisker suspension is obtained, wherein the nanocellulose whiskers have a diameter of 20-30nm and a length of 100- 150nm. The morphology of the prepared nanocellulose whiskers is shown in the transmi...

Embodiment 3

[0035] (1) Preparation of nanocellulose suspension

[0036] Cotton cellulose powder was ultrasonically pretreated in an ice bath for 15 minutes, filtered and dried for later use.

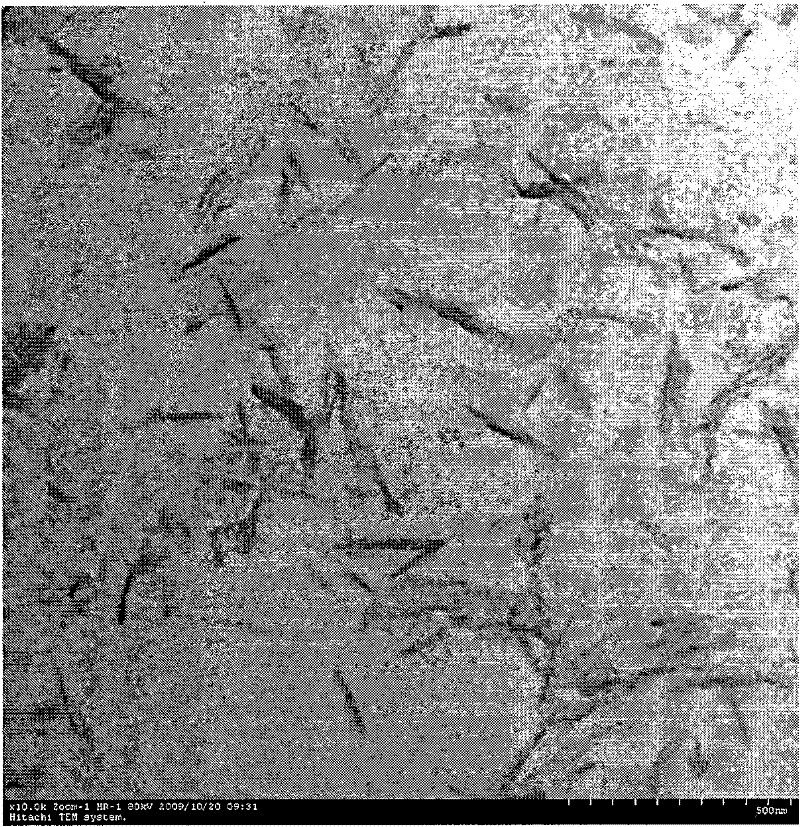

[0037] Immerse 0.5g of the above-mentioned cellulose powder accurately weighed in 16ml of sulfuric acid solution with a concentration of 64wt%, stir and react in a water bath at 75°C for 8h, then add 10 times the volume of deionized water to dilute the reaction solution; the diluted reaction solution Centrifuge at 8000 rpm; dialyze the suspension in deionized water for 24 hours until the pH is the same as that of the deionized water used. The molecular weight cut-off of the dialysis bag used is 8000-14000; finally, after 150w ultrasonic dispersion for 15min, a stable nanocellulose whisker suspension is obtained. Wherein, the nanocellulose whiskers have a diameter of 15-20nm and a length of 100-200nm. The morphology of the prepared nanocellulose whiskers is shown in the transmission electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com