Construction method for transversely strengthening railway bridge by utilizing prestressing steel structure

A technology of prestressed steel and structural pairs, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve problems affecting the normal operation of trains, and achieve good durability and flexible and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

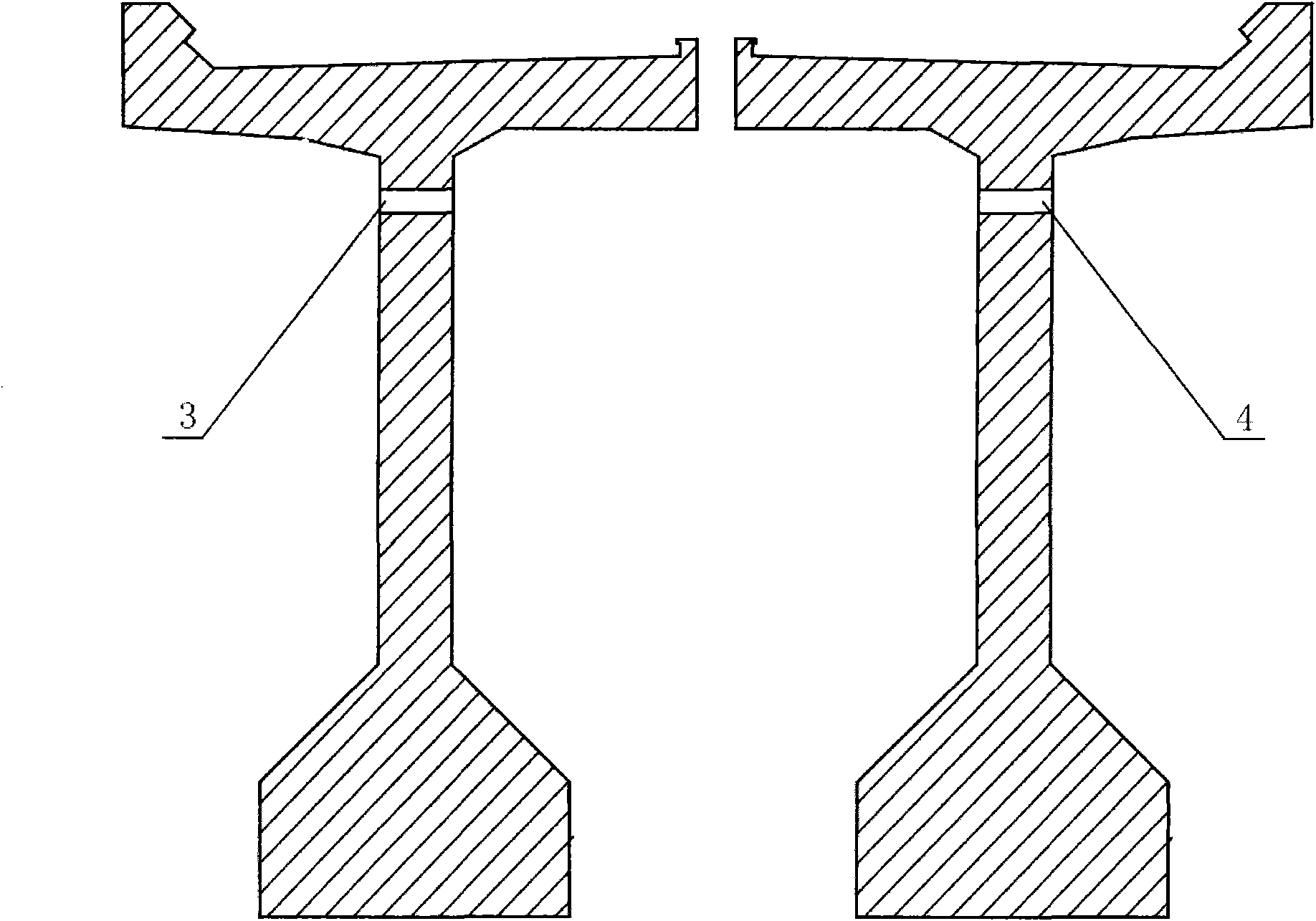

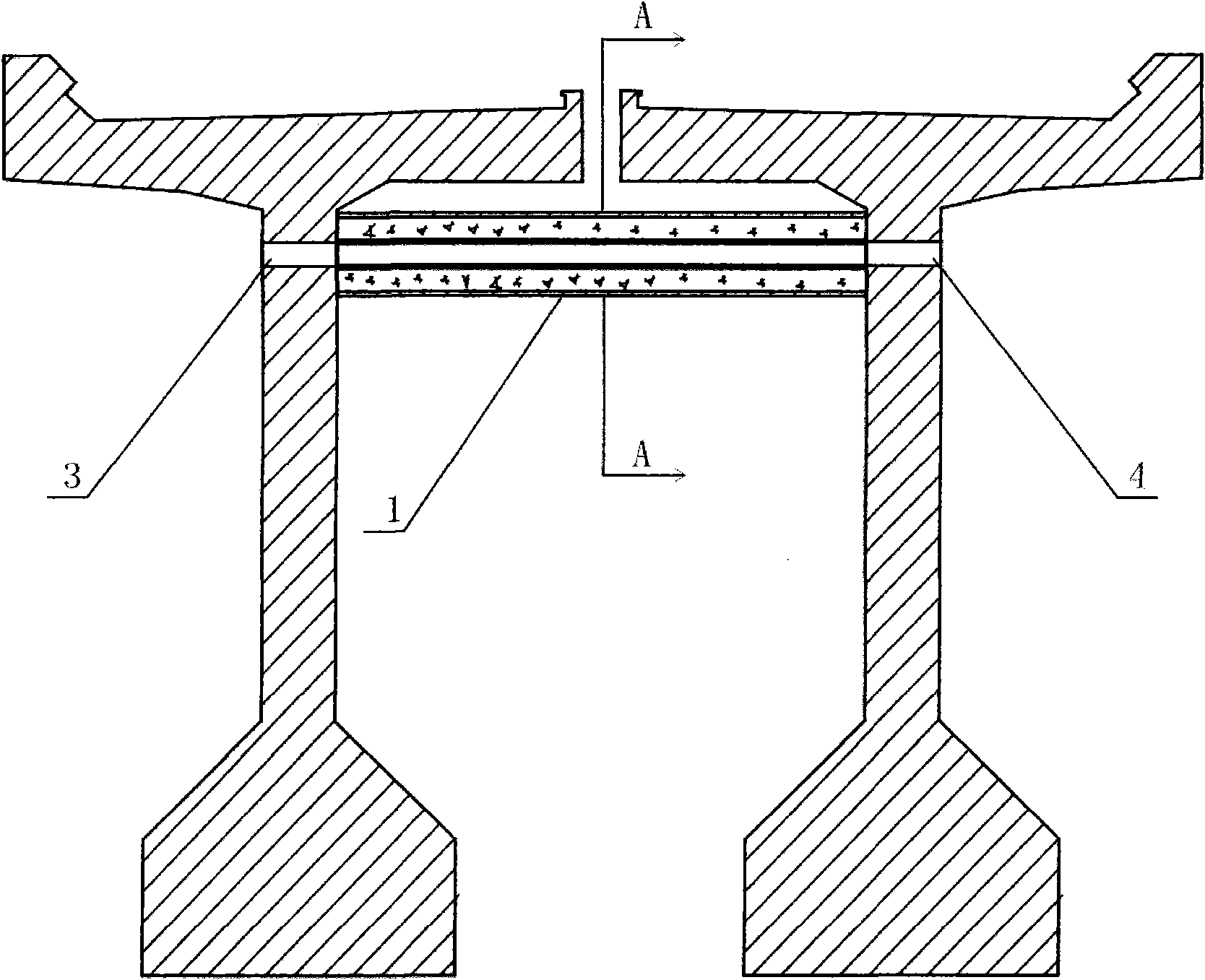

[0023] The construction method of the present invention will be further elaborated below in conjunction with the accompanying drawings. The lateral reinforcement system of the prestressed steel structure of the present invention is composed of lateral support steel members, cold-drawn four-stage finish-rolled threaded steel bars, neutral anti-corrosion grease and high-density polyethylene protective caps.

[0024] In conjunction with the accompanying drawings, the present invention uses the prestressed steel structure to carry out the detailed steps of railway bridge lateral reinforcement:

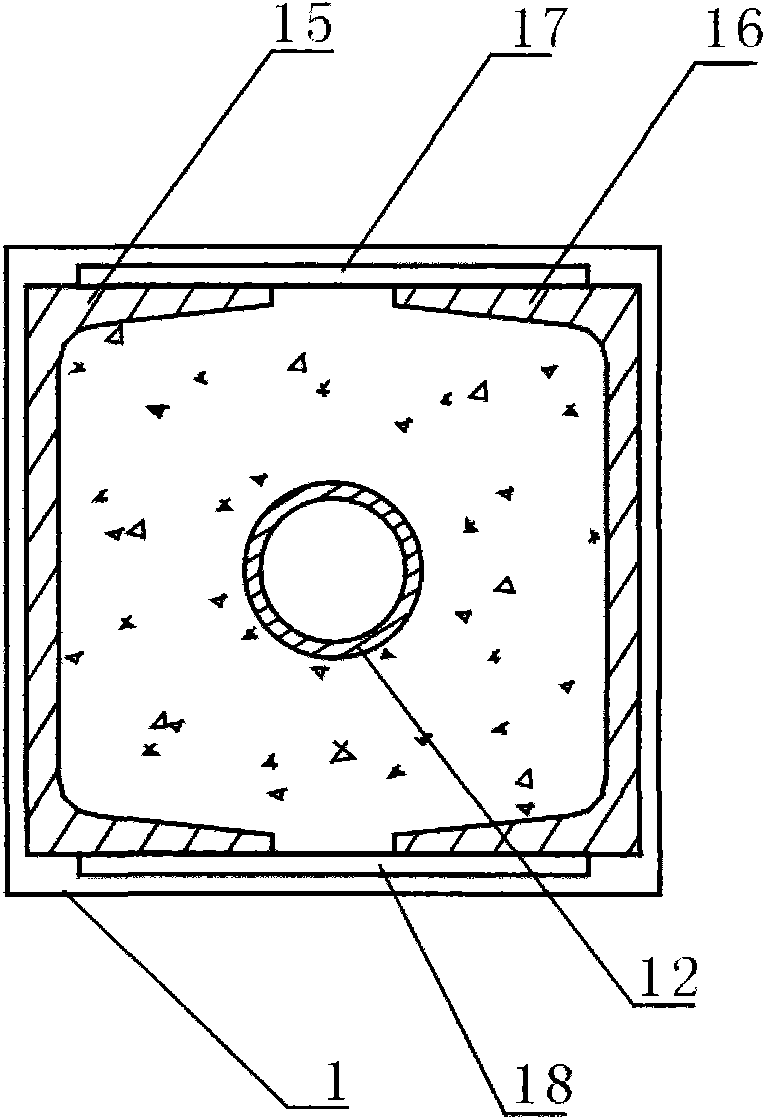

[0025] (1) The horizontal support steel member 1 is manufactured in a factory, and is treated with anti-corrosion protection, and the cold-drawn four-grade finish-rolled threaded steel bar 2 is ordered; the horizontal support steel member 1 is made of U-shaped channel steel 15, 16, steel plates 17, 18 and The seamless steel pipe 12 is formed; the seamless steel pipe 12 is placed in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com