Float switch

A float switch, float technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of high cost, easy to run out of control, control failure, etc., and achieve the effect of long service life, simple and low structure, and simple circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

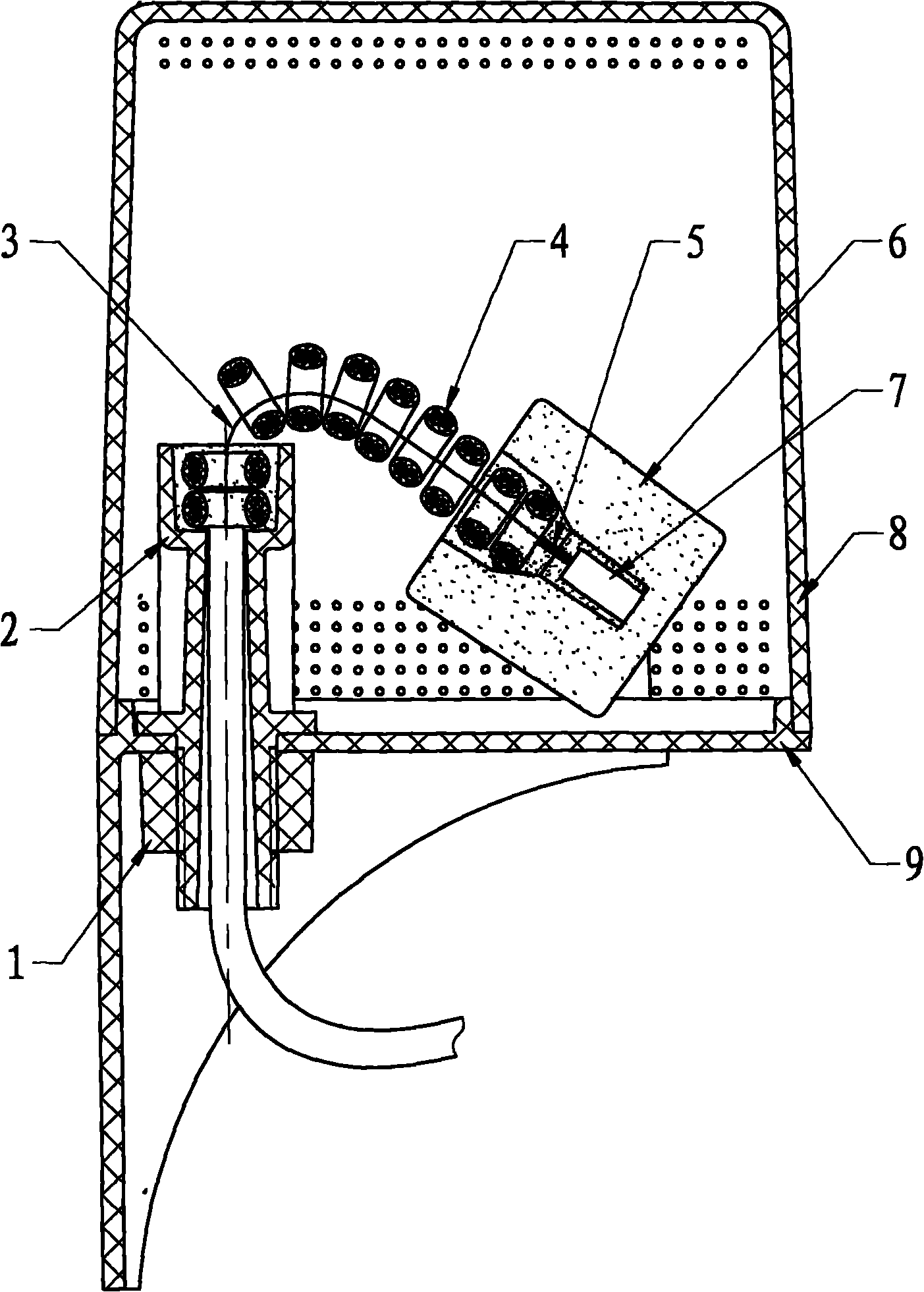

[0037] When the present invention is installed at a certain liquid height position to be controlled in the container through the mounting hole 9-3 of the mounting seat 9, the liquid passes through the upper filter hole 8-3 of the protective cover 8 as the height of the liquid in the container increases or decreases. 1 and the lower filter hole 8-2 flow into or out of the protective cover 8 of the float switch, and the float 6 rotates up and down around the pole 2 under the action of liquid buoyancy: when the float 6 rotates up to a certain angle, the float 6 The ball switch (or mercury switch) 7 in the float is closed; when the float 6 rotates and falls to a certain angle, the ball switch (or mercury switch) 7 in the float 6 is disconnected. The ball switch (or mercury switch) 7 in the float 6 is closed and disconnected to control the electric drive, so that the inflow and discharge of the liquid in the container can meet the requirement of controlling the liquid height in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com