Substrate classification method

A classification method and substrate technology, which are applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems of inability to change the order of unloading substrates, low classification efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below with reference to the drawings.

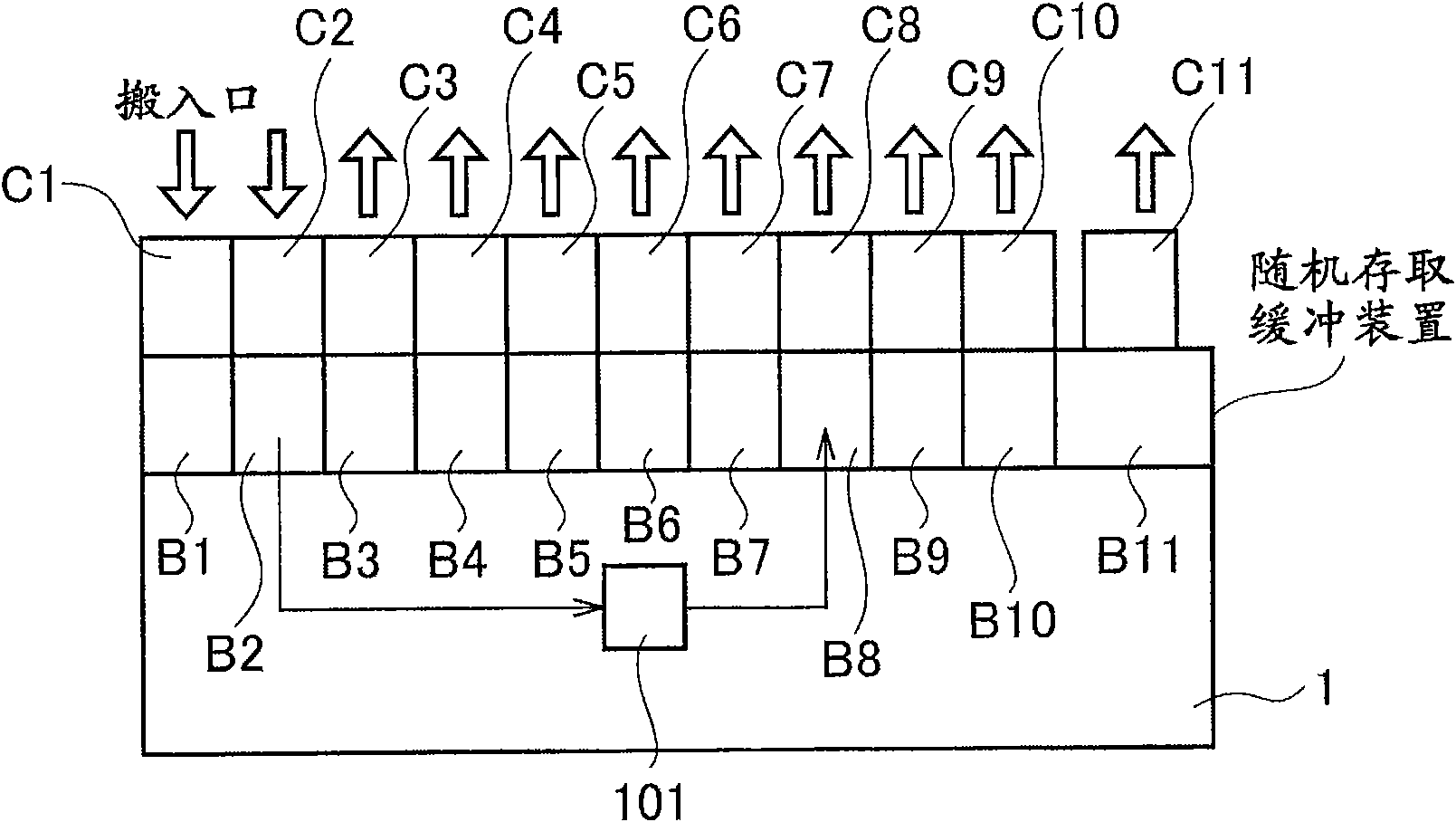

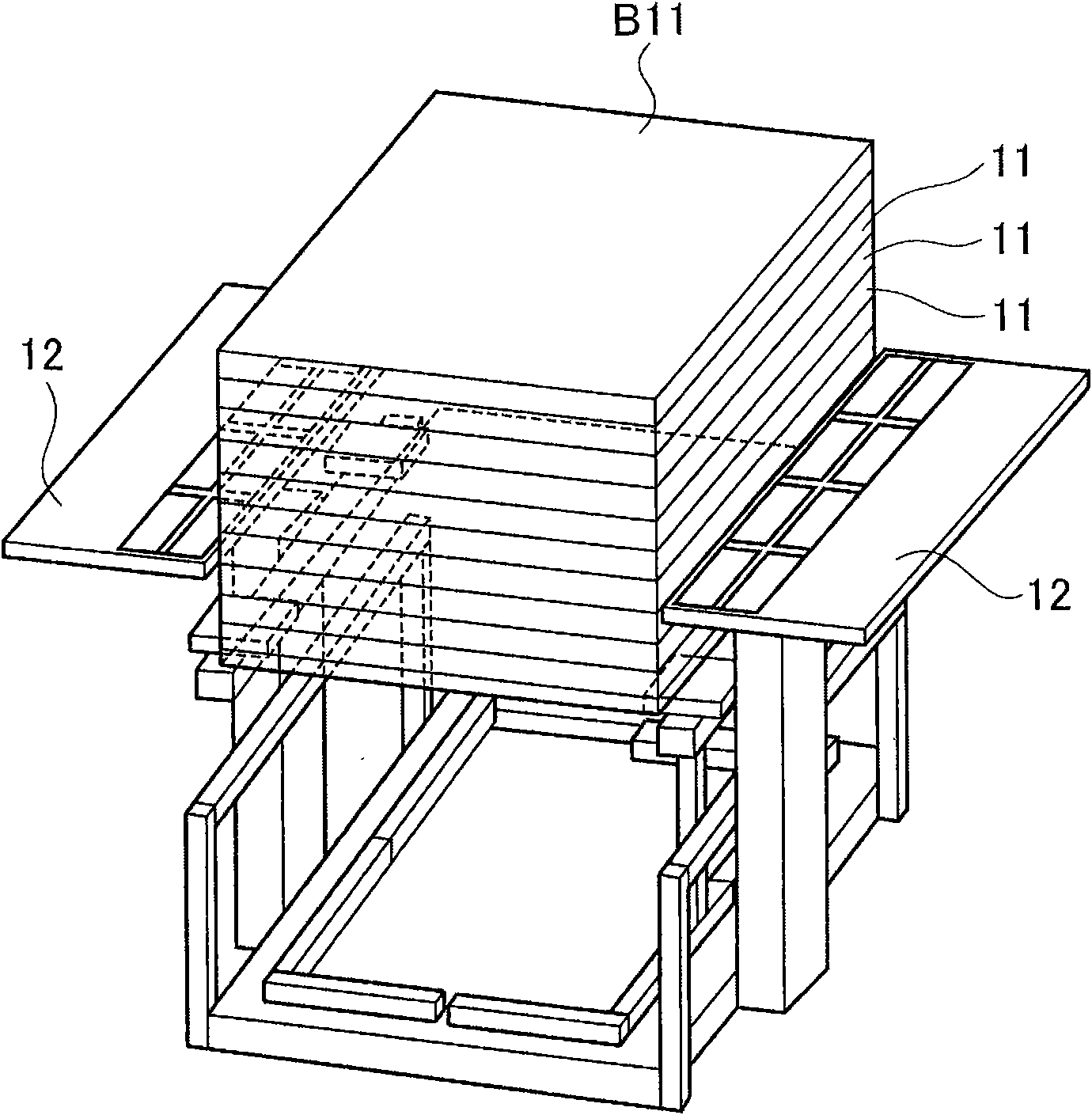

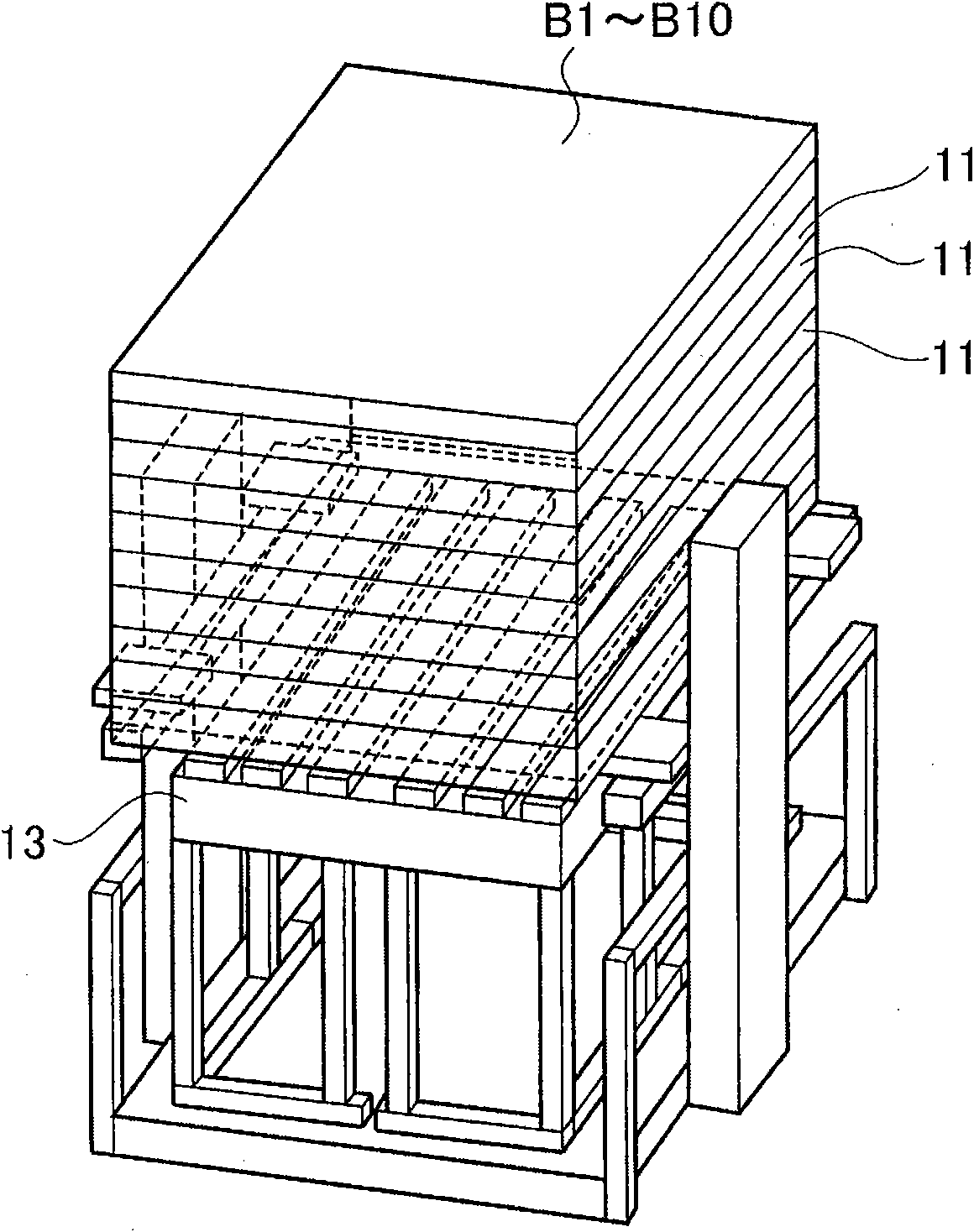

[0033] In the apparatus used in the substrate sorting method of this embodiment, such as figure 1 As shown, a plurality of substrates 101 of a plurality of types are stored in the cassettes C1 and C2 in a horizontally stacked state, and are loaded from at least one loading port. The loaded substrates 101 are sorted by type and transported to a sorting port corresponding to each type. The conveyed substrates 101 are carried out to the cassettes C3 to C11 provided at the respective sorting ports. In addition, the board|substrate sorting method of this embodiment is performed using the board|substrate sorting apparatus of this embodiment.

[0034] exist figure 1 In the illustrated substrate sorting apparatus, there are two entrances, and cassettes C1 and C2 accommodating a plurality of substrates 101 are installed at these entrances. In addition, the sorting port has nine loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com