Pressure cooker one-way valve

A pressure cooker and one-way valve technology, applied in pressure cookers and other directions, to achieve the effects of reducing convection, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

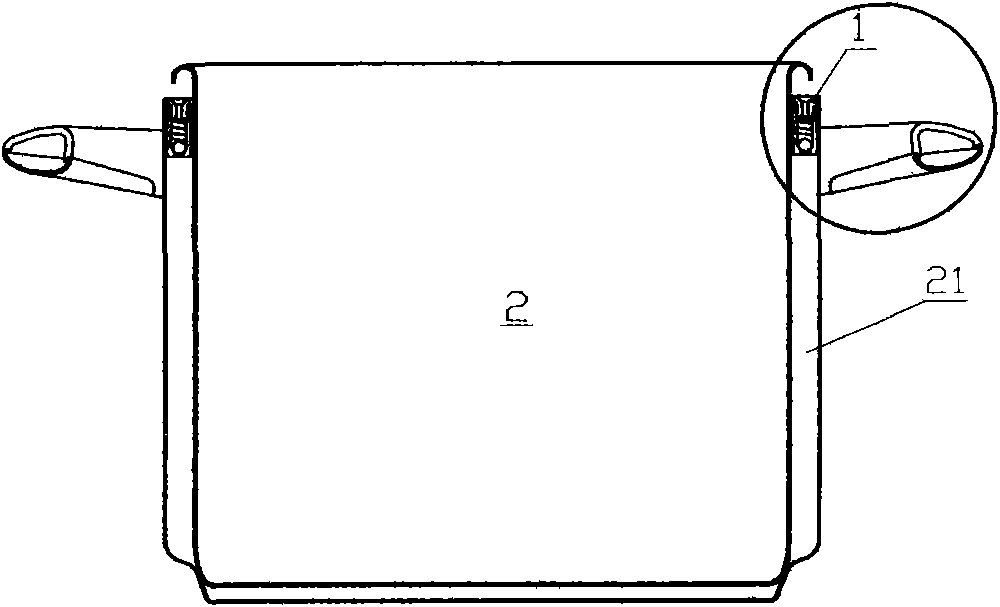

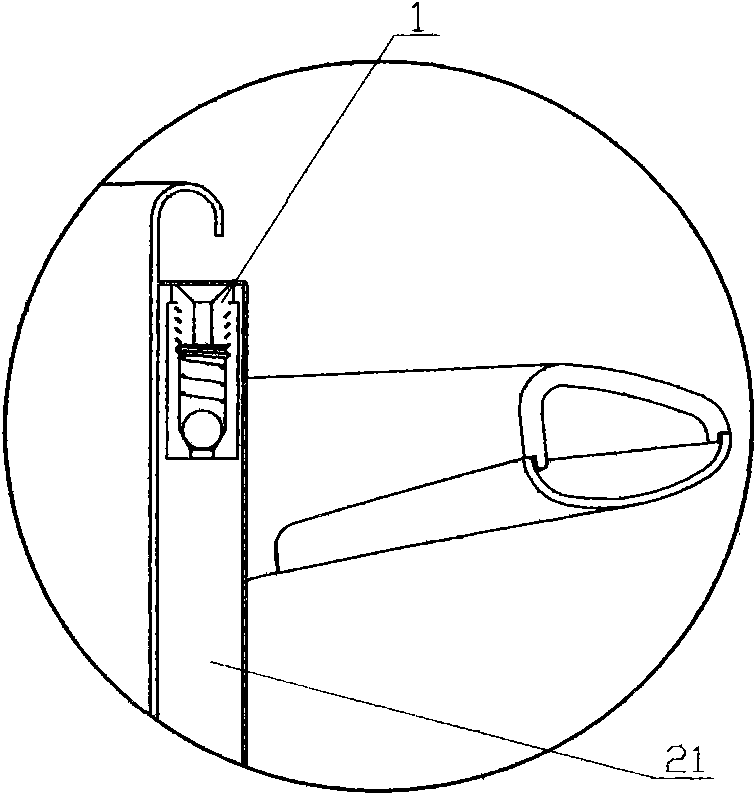

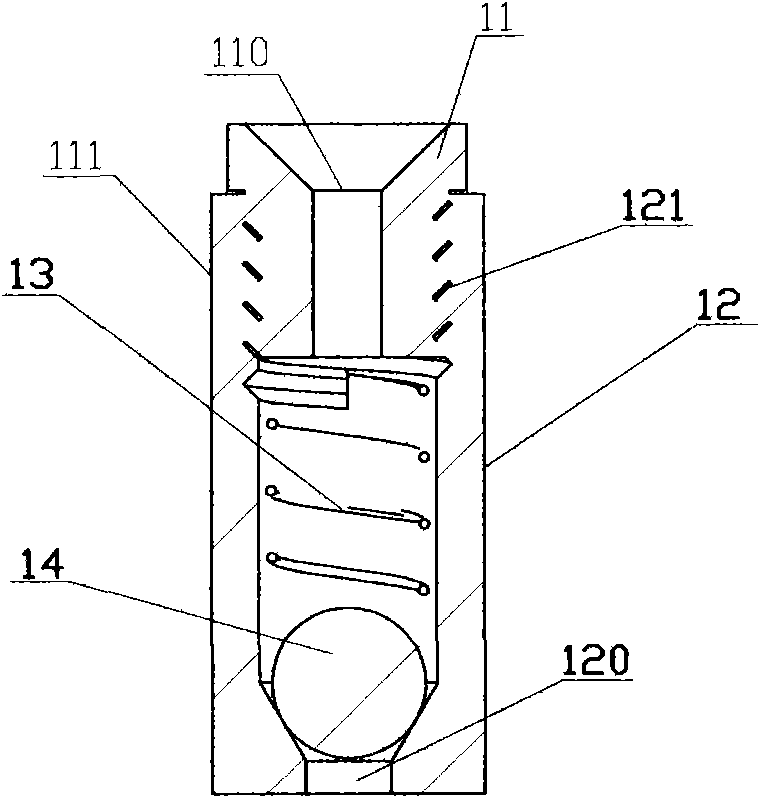

[0016] In a sandwich pressure cooker 2 with a jacket 21 made of stainless steel, the part valve body bolt 11 of a pressure cooker one-way valve 1 is welded to the inner wall of the top of the jacket 21, with the outer surface 111 of the bolt 11 in a circle Welding makes the bolt and the inner wall of the jacket into one body, and there is no space on the outer surface of the bolt to allow the airflow to rise; and above the center of the bolt of the valve body, there is a small exhaust hole 110, correspondingly There is also a small round through hole at the top of the jacket layer corresponding to the bolt, so that the above two small holes are on the same centerline and communicate, that is, if the gas from the bolt is exhausted from the exhaust hole 110, you can It is discharged to the outside of the pot through the round through hole on the jacket.

[0017] The pressure cooker one-way valve of the present invention is composed of a valve body bolt 11, a valve body 12, a spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com