Magnetic bouncing board

A springboard, magnetic technology, applied in springboard and other directions, can solve the problems of weak spring force, large mechanical noise, mechanical wear, etc., and achieve the effect of overcoming large mechanical noise, good elasticity and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

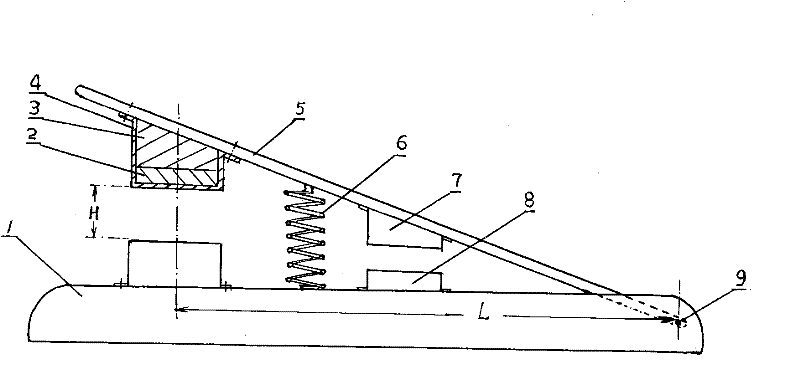

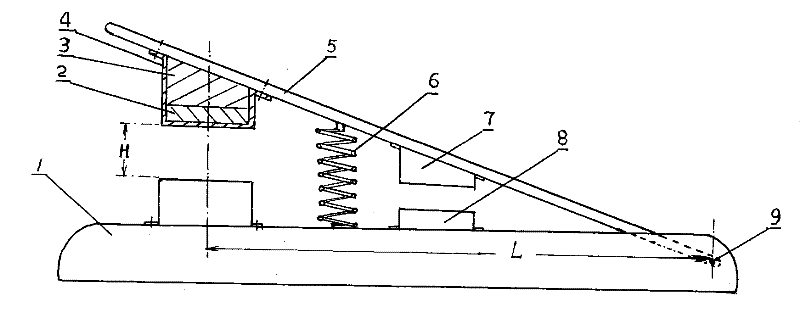

[0009] Among the figure: 1, base, 2, magnet sheet, 3, spacer, 4, fixed sleeve, 5, panel, 6, spring, 7, upper magnetic pad, 8, lower magnetic pad, 9, panel rotating shaft.

[0010] Base 1 is made of solid wood or metal plate, and panel 5 can be assembled with firm and elastic wooden strips, and the moso bamboo sheets are bound on the wooden strips for strengthening its elasticity and firmness. Panel 5 can also be made of sheet metal. The magnet sheet 2 is made of NdFeB magnetic sheet, and the fixed sleeve 4 is a stainless steel cover, which is fixed on the top of the base 1 or below the panel 5 by screws, and the magnet sheet 2 and spacer 3 are fixed together in the fixed sleeve 4 to prevent the magnet sheet 2 from damaged in use.

[0011] When calculating with the formula H=3L / 40, L is the distance from the centerline of the magnetic pad 3 to the panel rotation axis 9 . The error range of the distance H between the upper and lower magnetic pads 7, 8 should be within 15%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com