High-temperature molten material feeding receptor with loop type flange port

A high-temperature melting and receiver technology, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting normal production, connection angles cannot be adjusted, and machines cannot operate normally, so as to improve the appearance quality , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

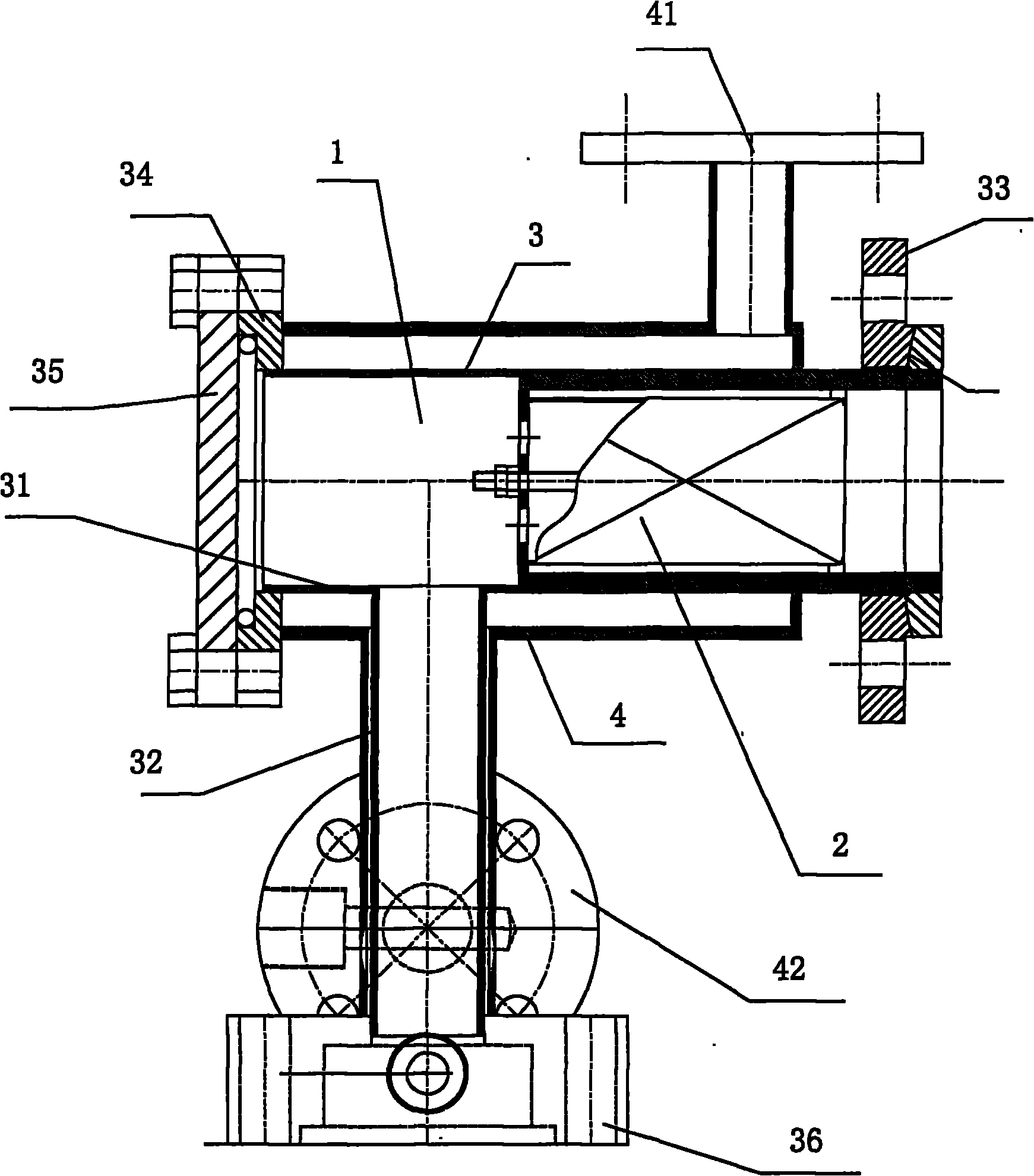

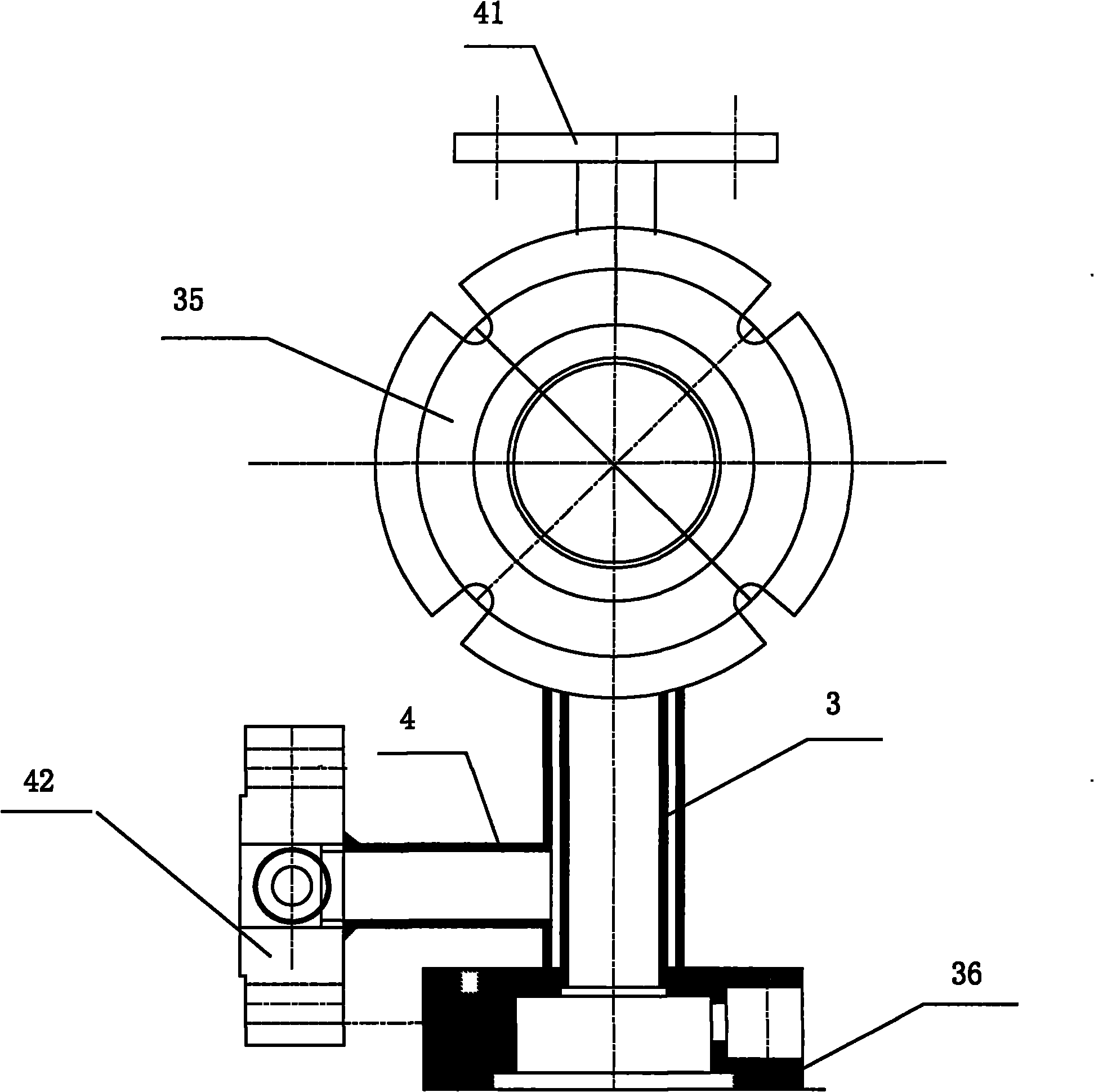

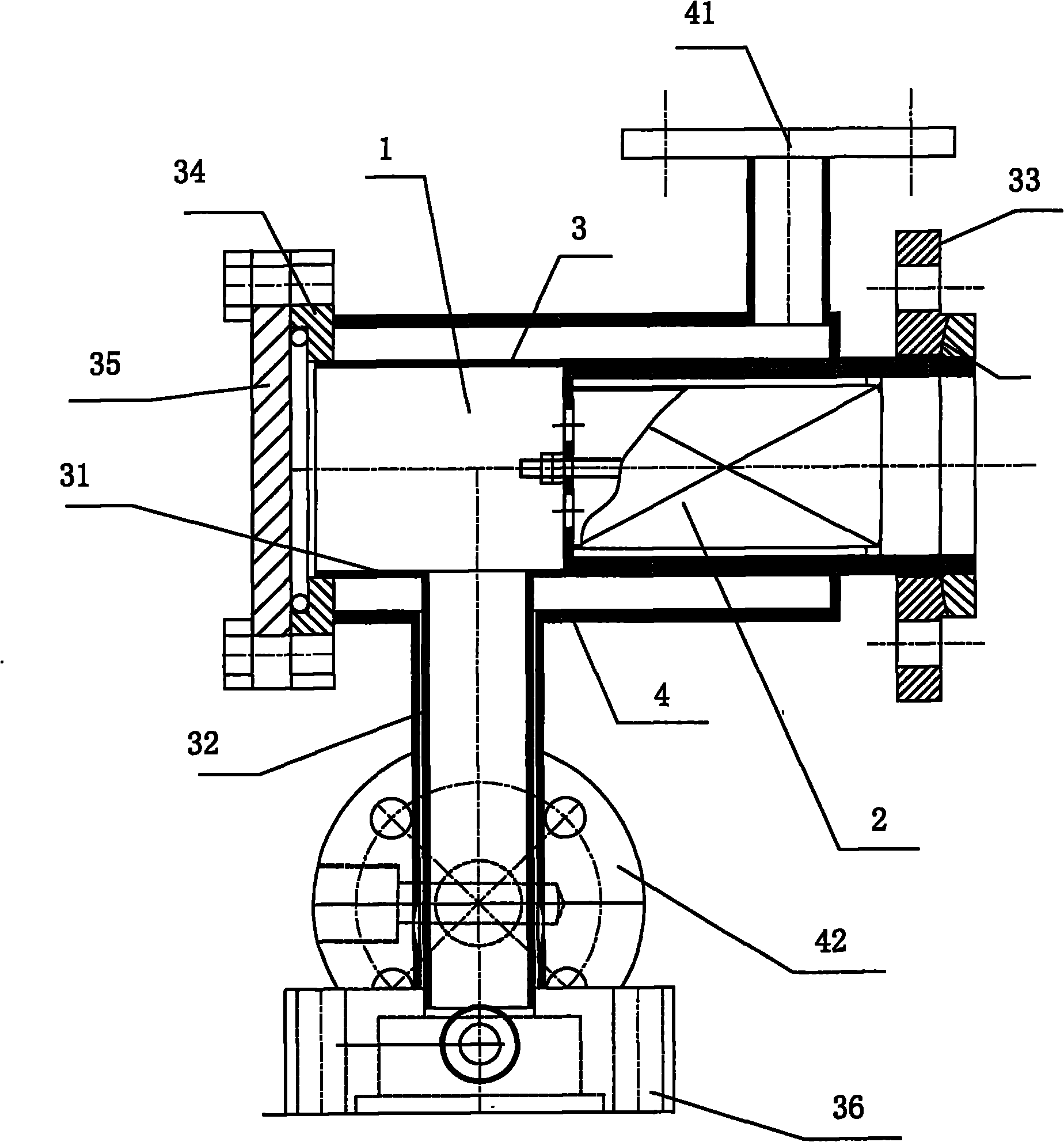

[0009] The specific embodiments are described in detail below in conjunction with the accompanying drawings: Figure 1 to Figure 2 In one embodiment of the present invention shown, a high temperature molten material feed receiver with a looper flange port is special in that the feed receiver is composed of a double pipe structure 1 and a filter 2 The double pipe structure consists of an inner pipe 3 for conveying high-temperature molten materials and an outer pipe 4 wrapped around the outer layer of the inner pipe to form a thermal insulation channel; the outer pipe is provided with an inlet end flange 41 and an outlet end method Lan 42, the inner pipe 3 at least has a through pipe 31 and an overhanging pipe 32 connected with the through pipe, the through pipe is the output end of the feed receiver, and both ports of the through pipe extend out of the outer pipe body, one of which is the output end of the feed receiver. The port is a looper flange 33, the other end is a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com