Positioning compaction device, compaction device and tool for auxiliary machining of chassis of motor train

A pressing device and auxiliary processing technology, applied in the direction of positioning device, workpiece clamping device, metal processing equipment, etc., can solve the problems of large volume, poor adjustability, inconvenient handling and movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

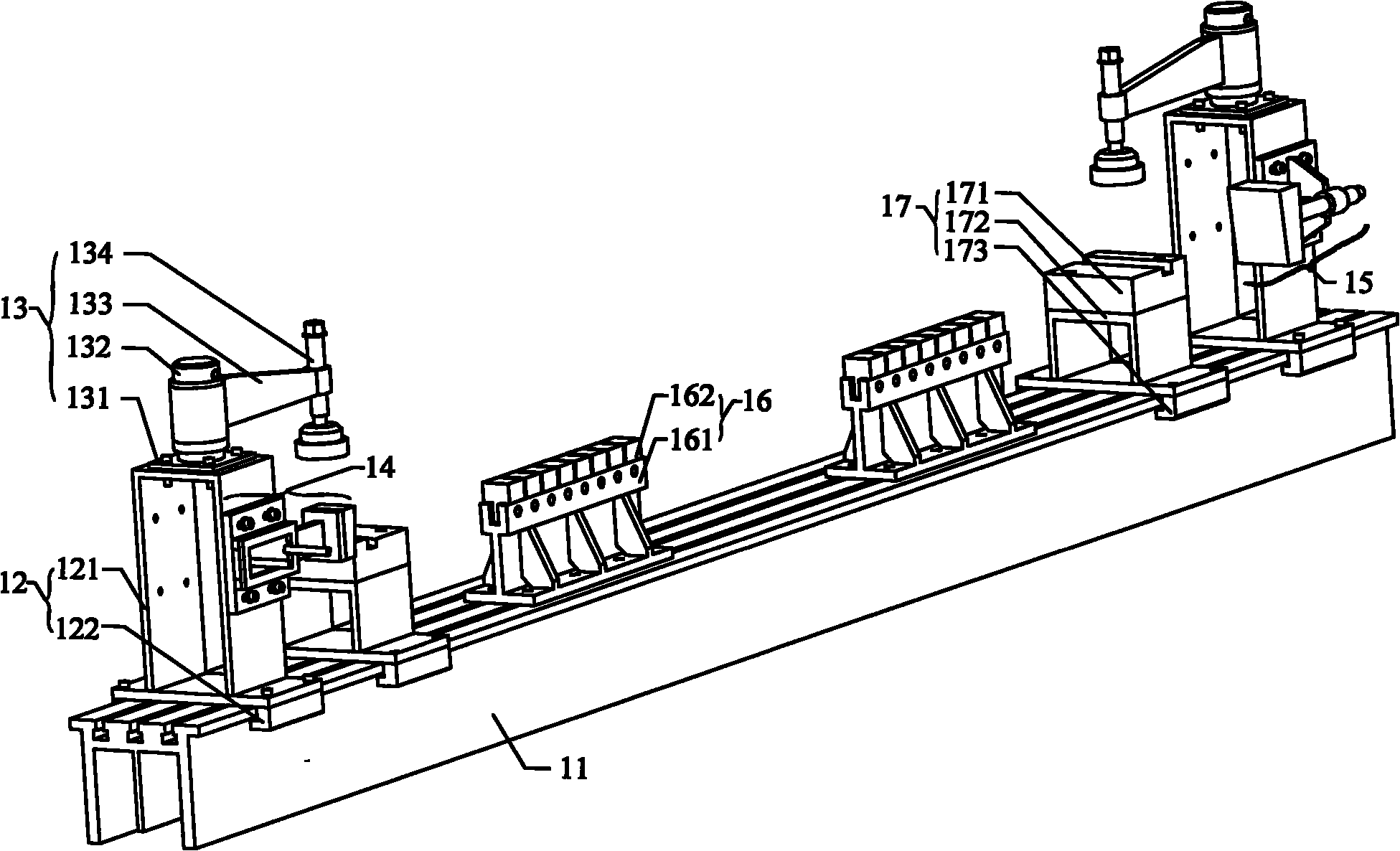

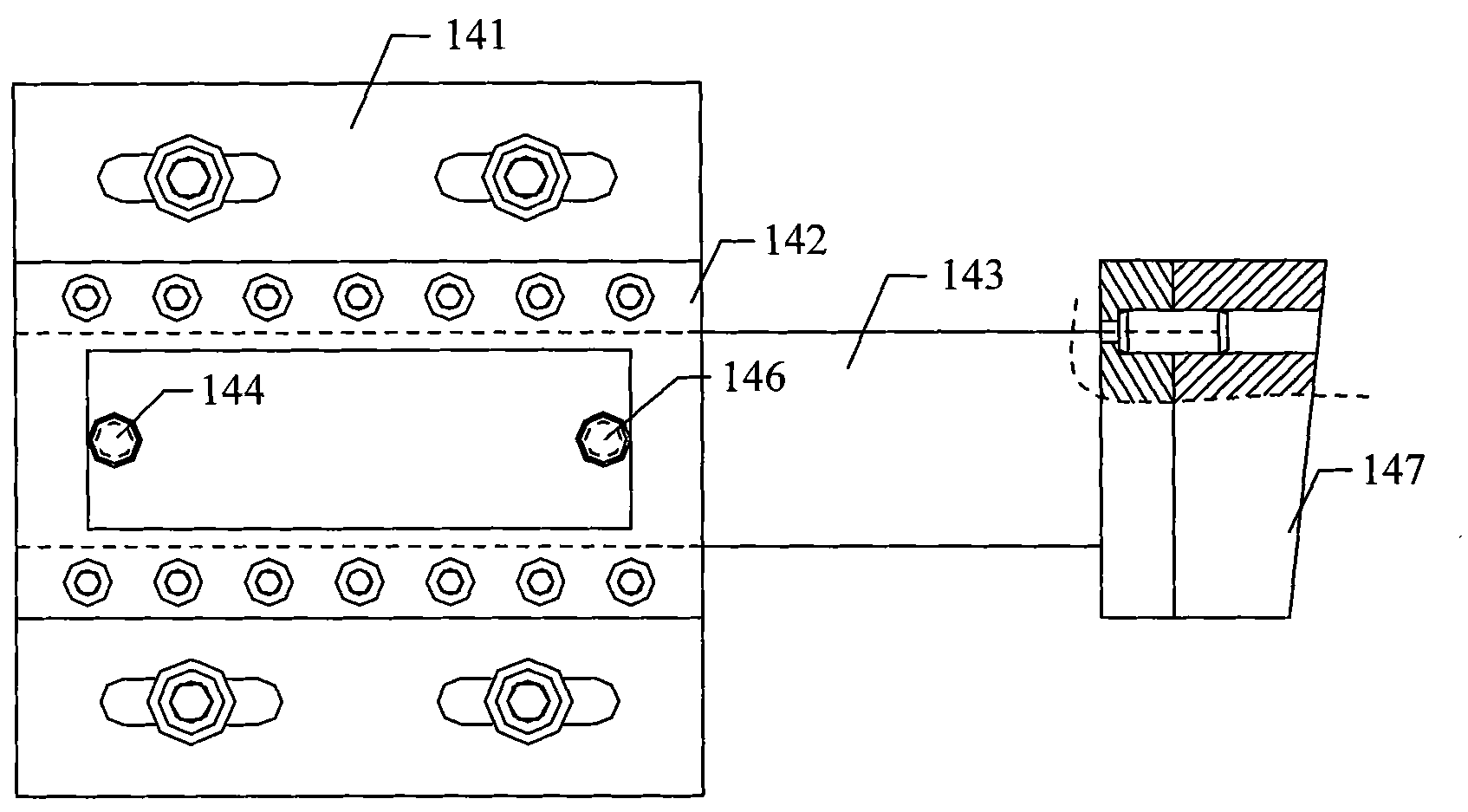

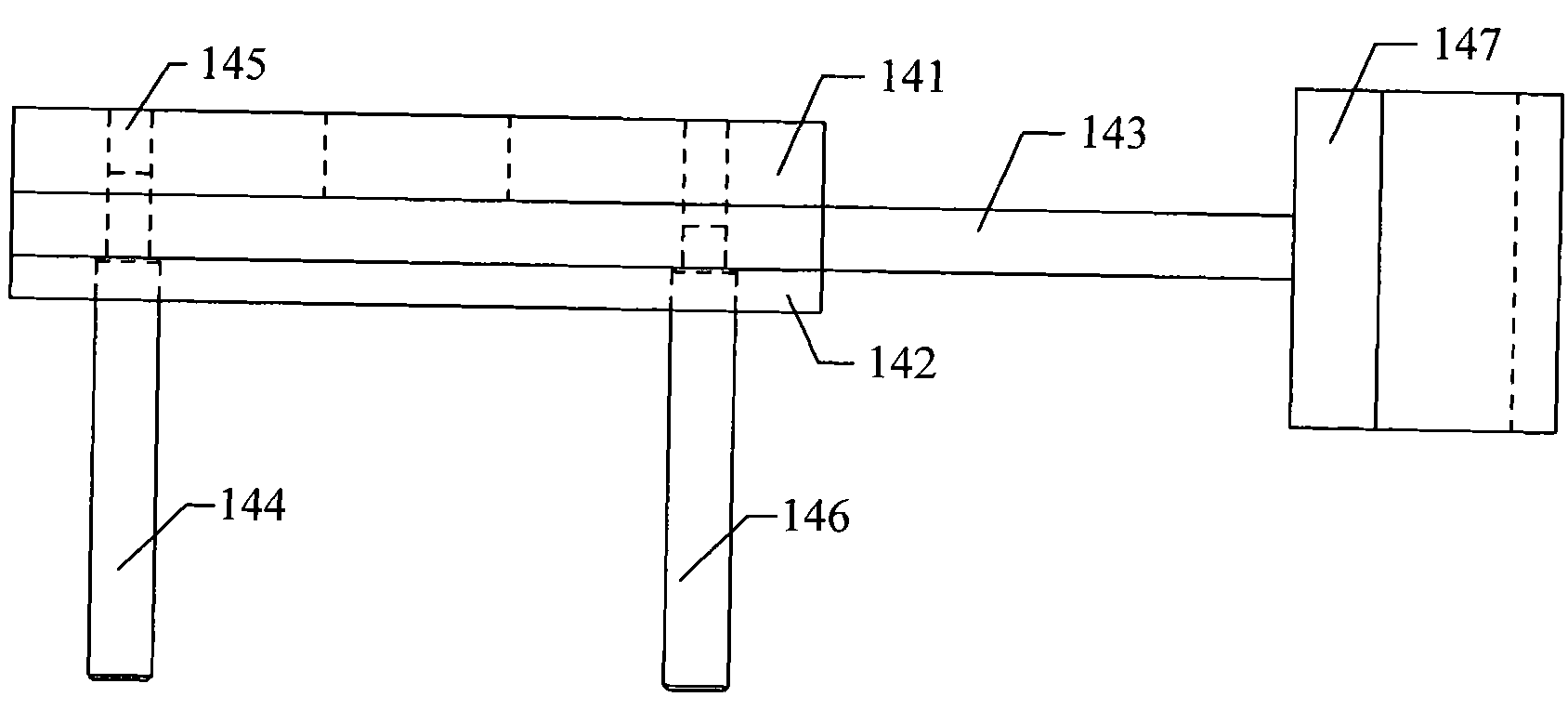

[0035] figure 1 It is a perspective view of the positioning and pressing device for auxiliary processing of the underframe of the motor car according to the present invention. figure 2 It is a front view of the side positioning structure of the positioning and pressing device of the present invention. image 3 It is a top view of the side positioning structure of the positioning and pressing device of the present invention. Figure 4 It is a front view of the lateral pressing structure in the positioning and pressing device of the present invention. Figure 5 It is a top view of the lateral pressing structure in the positioning and pressing device of the present invention. Image 6 It is a front view of the adjustable intermediate support structure in the positioning and pressing device of the present invention. Figure 7 It is a side view of the adjustable intermediate support structure in the positioning and pressing device of the present invention. Figure 8 It is a top view of...

Embodiment 2

[0046] Figure 15 It is a three-dimensional view of the pressing device for auxiliary processing of the underframe of the motor car according to the present invention. Combine Figure 1 to Figure 15 As shown, the pressing device of this embodiment differs from the positioning and pressing device of the first embodiment only in that there is no side positioning structure 14 and lateral pressing structure 15, and the rest of the structure is the same as that of the positioning and pressing device, which will not be repeated here. .

Embodiment 3

[0048] Further, the tooling for auxiliary processing of the underframe of the motor car in this embodiment includes a plurality of positioning and pressing devices of the first embodiment; or, a plurality of positioning and pressing devices of the first embodiment and a plurality of pressings of the second embodiment. The tightening device, in addition, the tooling can be provided with at least one positioning and pressing device corresponding to the two ends of the motor car underframe.

[0049] specifically, Figure 16 It is a schematic diagram of the tooling used for auxiliary processing of the underframe of the electric vehicle to clamp the underframe of the electric vehicle. Such as Figure 16 As shown, the tooling for auxiliary processing of the motor car underframe in this embodiment includes three positioning and pressing devices 21 in the first embodiment above and eight pressing devices 22 in the second embodiment above to perform the processing of the underframe of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com