Electron beam emission apparatus for rubber spew prevention of tire tread

An irradiation device and electronic wire technology, applied in tires, applications, household appliances, etc., can solve problems such as difficulty in maintaining the inherent characteristics of the sidewall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

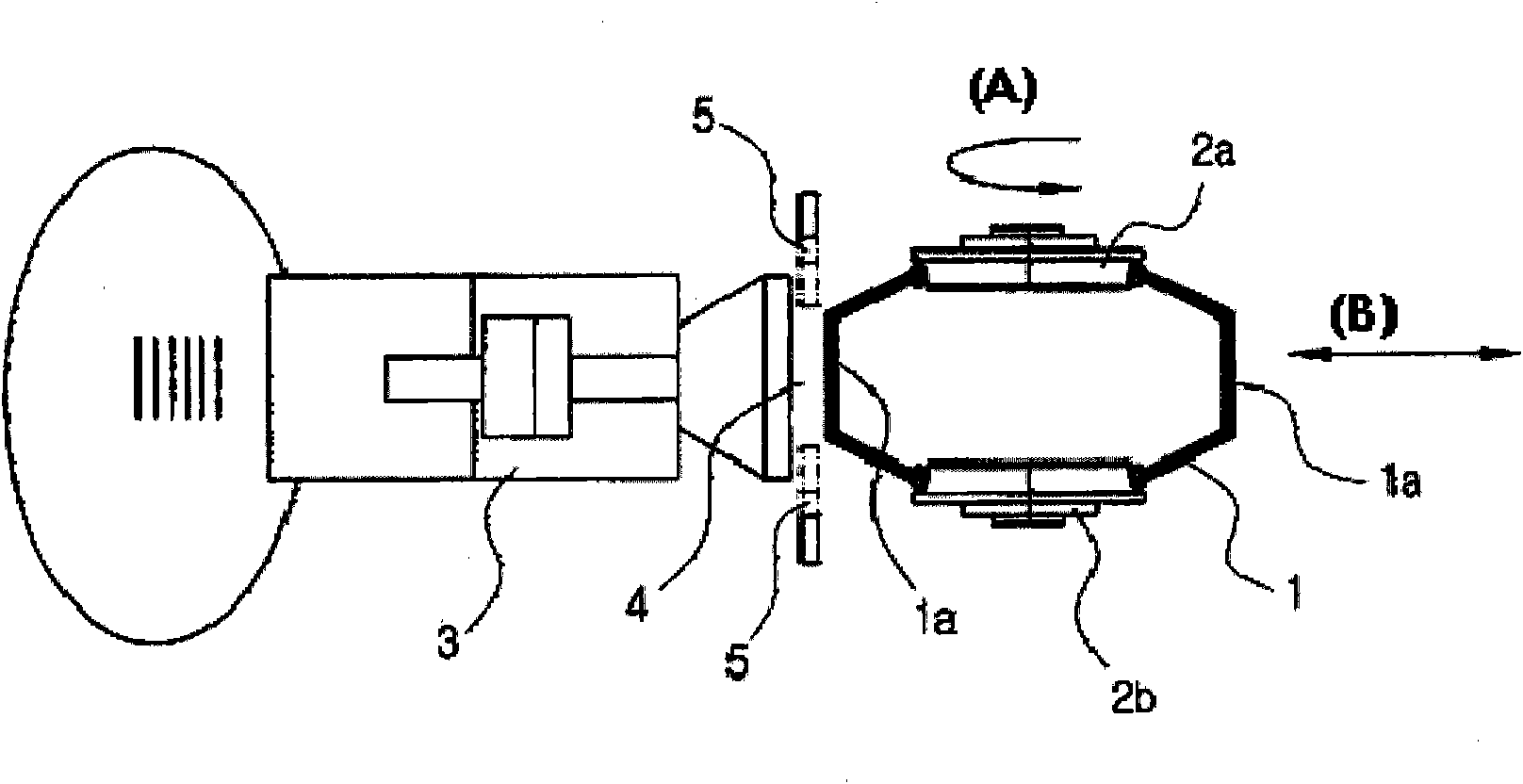

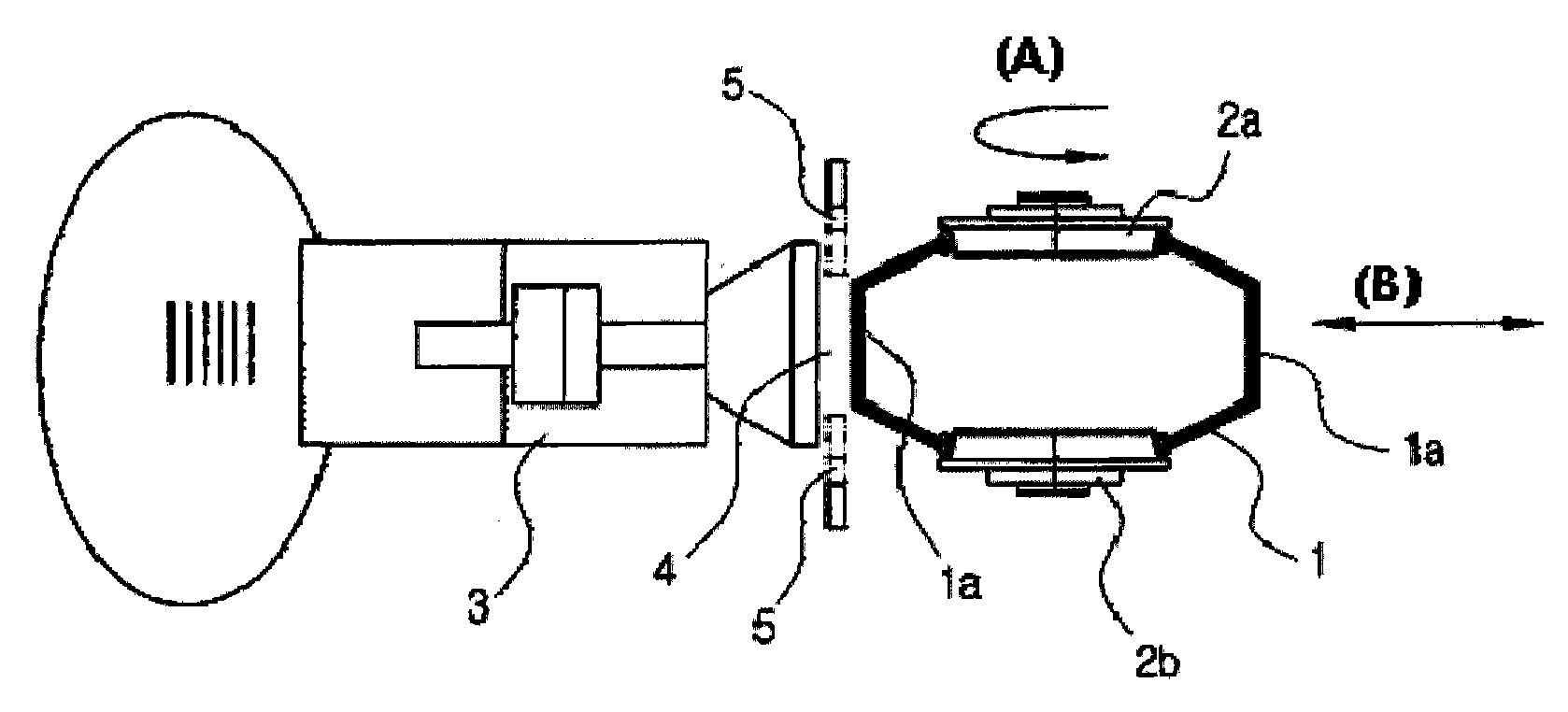

[0012] The present invention will be described in detail below with reference to the accompanying drawings.

[0013] figure 1 It is a diagram showing the overall configuration of an electron beam irradiation device for preventing exudation from a tread portion of a green tire according to the present invention.

[0014] The present invention is constituted to include: upper and lower expansion rims 2a, 2b, which fix and maintain tire blanks 1 of various specifications under a certain pressure and make them rotate; electron beam irradiators 3 are arranged on the above-mentioned upper and lower expansion rims 2a, 2b at a certain interval. The tread portion 1a of the green tire 1 is provided separately; and the electron beam shielding film 5 has the electron beam penetration portion 4 arranged between the green tire 1 and the electron beam irradiator 3, so that the tire on the green tire 1 Parts other than the face 1a were not irradiated with electron beams.

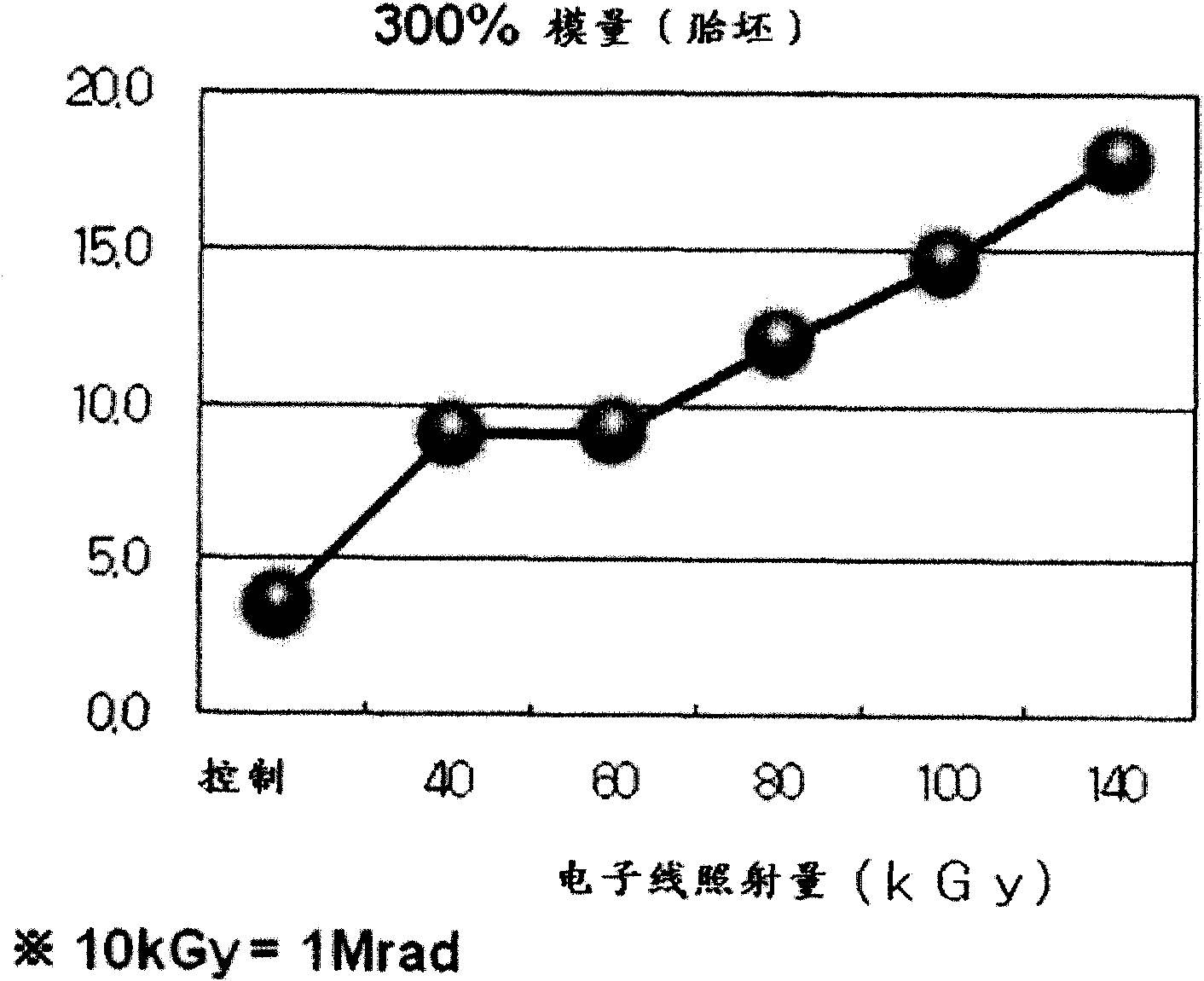

[0015] In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com