Method for preparing high-purity garlic polysaccharide by co-precipitation of cinchona alkaloid-derived quaternary ammonium salt

A technology of garlic polysaccharide and cinchona alkaloid, applied in the field of phytochemistry, can solve the problems of low effective yield of equipment, not easy to dissociate, and extraction cannot be continuously performed, etc., and achieves the effect of avoiding decomposition of garlic polysaccharide and avoiding quality deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Degreasing pre-treatment: After peeling the garlic, vacuum-dry it at 35-40°C to constant weight, then chop it until the particle size is 200-300 mesh to obtain 5.0kg minced garlic, and put the minced garlic in a 100L stainless steel high-pressure airtight container , add the mixed solution of 25kg acetone and tetrahydrofuran (according to volume ratio calculation, acetone / tetrahydrofuran=95:5), stir and disperse for 10-20min, then add 25kg of dry ice with a particle size of 0.5-1cm from the feed port, close the feed port, and Stir at room temperature, and stop stirring when the temperature in the kettle naturally rises to 0-5°C; press filter to remove the filtrate, and vacuum-dry the filter cake at 35-40°C to constant weight to obtain 4.91kg of degreased primary garlic residue;

[0035] 2) Low-temperature ultrasonic removal of small molecular sugars: Add 4.91kg of defatted primary garlic residues to 27kg of 90% V ethanol aqueous solution, ultrasonicate at 10-20°C for ...

Embodiment 2

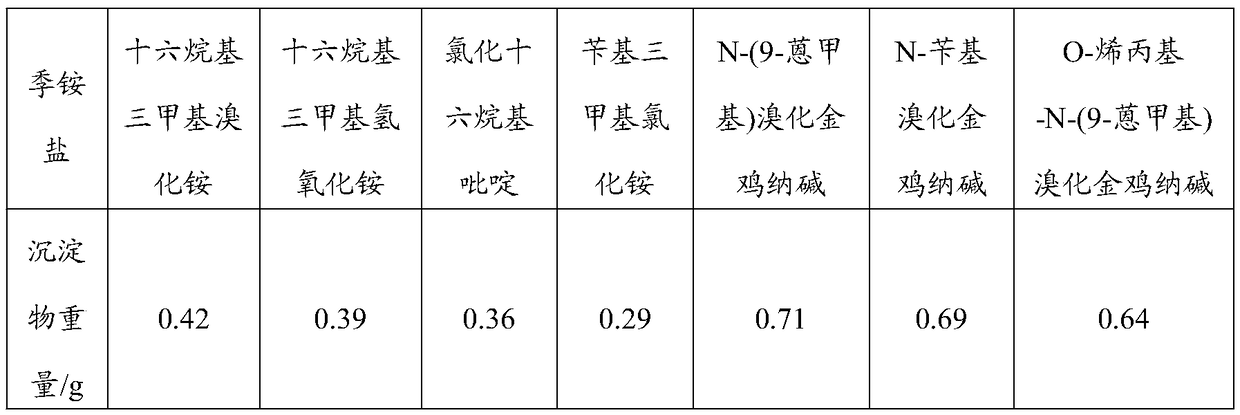

[0043] Take 1.0g of Pre-garlic polysaccharide respectively, add 50ml of water to dissolve, then add 50ml of different quaternary ammonium salt solutions with a concentration of 2%wt, let stand at 40°C overnight (8-12h), then cool down to room temperature, centrifuge, After drying, the quality of the precipitate was detected, and the results are shown in Table 1:

[0044] Table 1 Co-precipitation effect of different quaternary ammonium salts on garlic polysaccharides

[0045]

[0046] The above results show that the use of cinchona base quaternary ammonium salt for co-precipitation with garlic polysaccharides can obtain a high-yield precipitate, compared with the traditional cetyltrimethylammonium bromide (CTMAB) and its cetyl Compared with trimethylammonium hydroxide (CTA-OH) and cetylpyridinium chloride (CPC), the yield is greatly improved.

Embodiment 3

[0048] In the present invention, each 1 g of precipitates formed by N-(9-anthracenylmethyl) cinchonaline bromide and N-benzyl cinchonaine bromide is adopted, and 160ml of 2mol / L different inorganic salt aqueous solutions are used at 35-40° C. Carry out dissociation for 4-6 hours, centrifuge to obtain the filtrate, then add absolute ethanol dropwise to the filtrate until no solid precipitates, collect the solid by filtration, dry and weigh it under vacuum at 40-45°C, and obtain high-purity garlic polysaccharide dissociated from different inorganic salts , the weight of garlic polysaccharide obtained by different inorganic salts is shown in Table 2:

[0049] The weight of the garlic polysaccharide obtained by the dissociation of different inorganic salts in table 2

[0050]

[0051] The above results show that different inorganic salts have different dissociation effects, among which ammonium bisulfate has the best dissociation effect; different quaternary ammonium salts have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com