A Workpiece Dimension Measuring Instrument for CNC Milling Center

A CNC milling and measuring instrument technology, applied in measuring devices, electromagnetic measuring devices, electric/magnetic diameter measurement, etc., can solve the problems of low measurement accuracy, inevitable processing size deviation, etc., optimize the processing technology and reduce auxiliary measurement man-hours , the effect of meeting the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

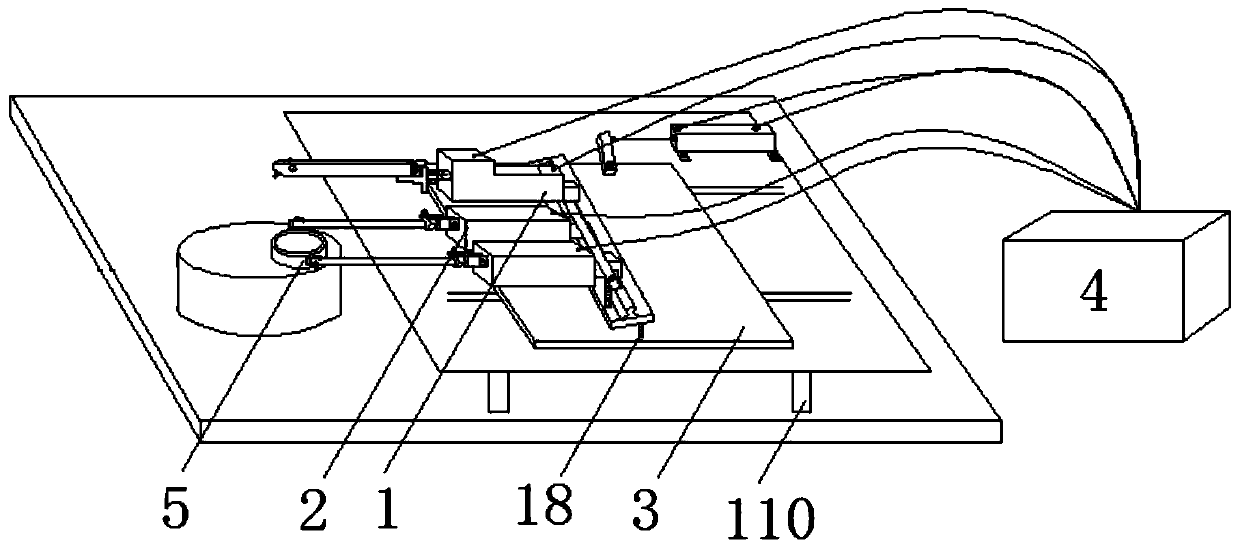

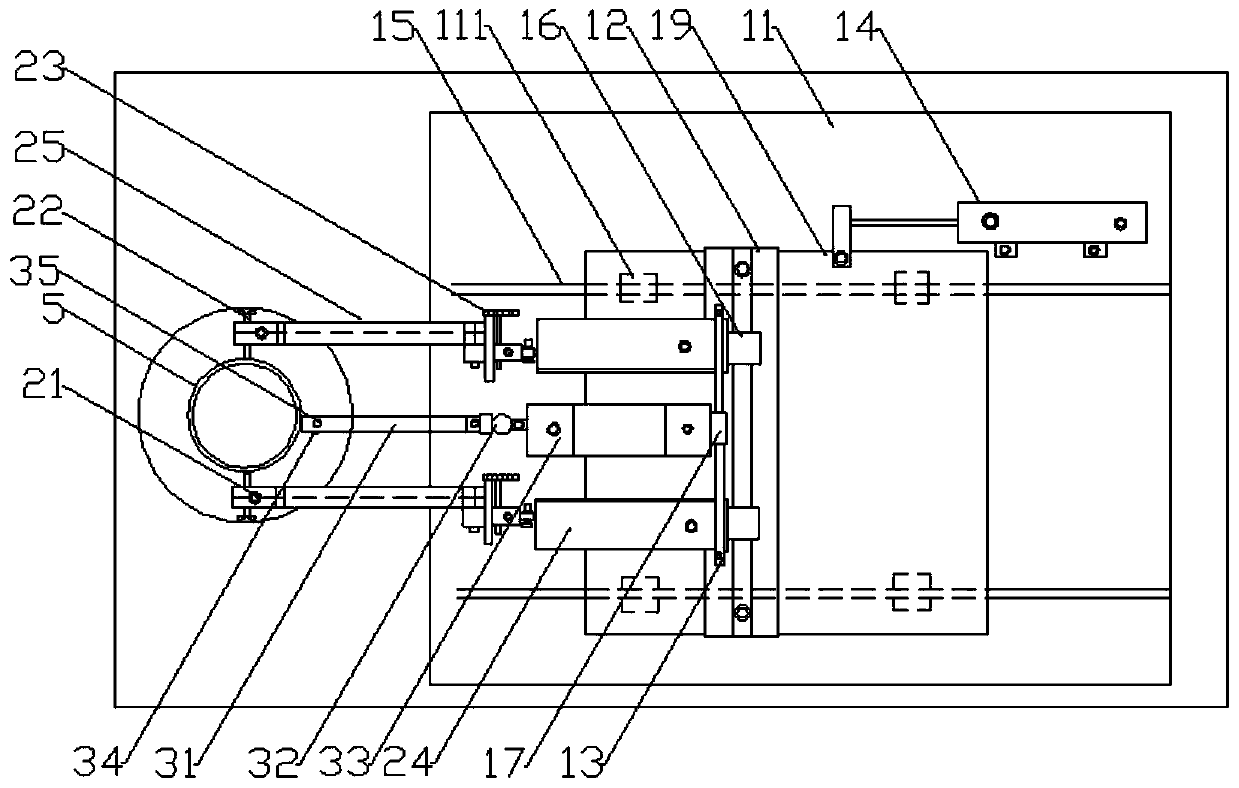

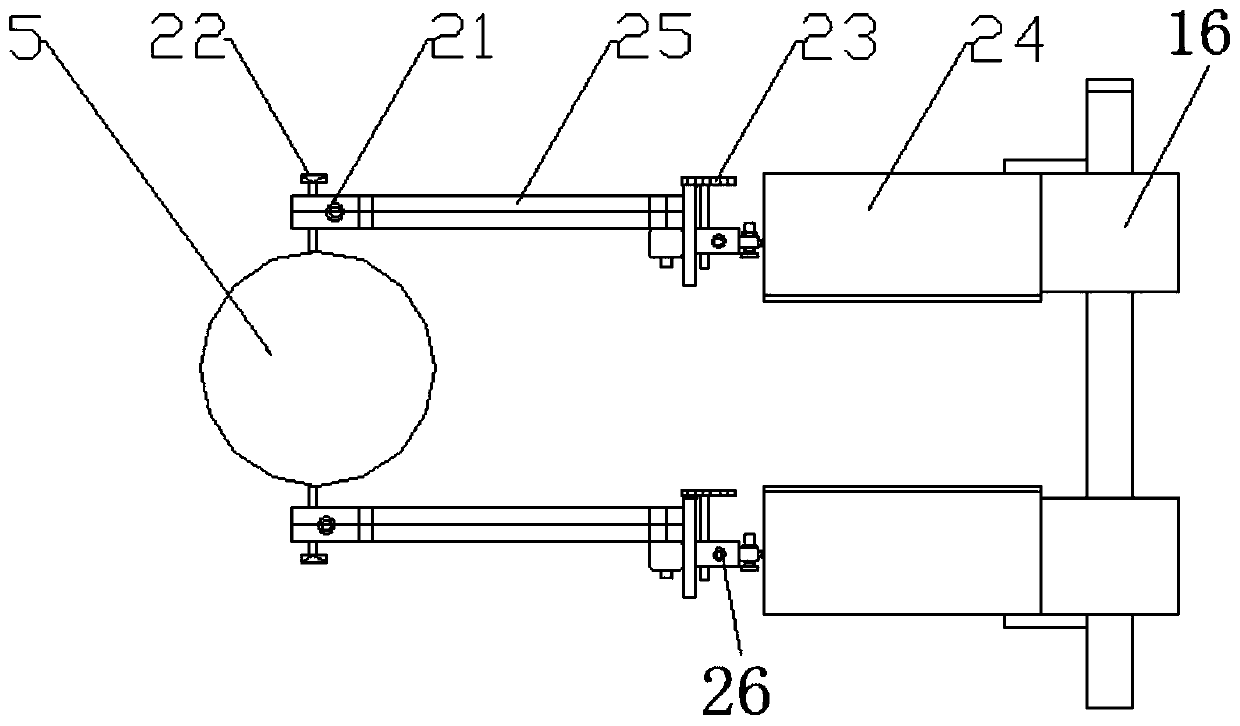

[0021] The invention provides a workpiece size measuring instrument for a numerically controlled milling machining center (see Figure 1-5 , referred to as dimension measuring instrument), including a driving device 1, a radial measuring device 2, an end surface measuring device 3 and a controller 4;

[0022] The driving device 1 includes a base plate 11, a radial probe support 12, an end surface probe support 13, a measuring device advancing and retreating cylinder 14, a linear guide rail 15, a radial measuring device slider 16, an end surface measuring device slider 17, and a stud 18 , a slide plate 19, an adjustable bolt 110 and a slide block 111; the base plate 11 is connected with the machine tool workbench by an adjustable bolt 110; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com