Ring rib type manhole cover

A technology of manhole cover and ring reinforcement, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of inconvenient transportation and installation, waste of materials, etc., and achieve the goal of improving pressure bearing capacity, saving materials, and improving compressive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

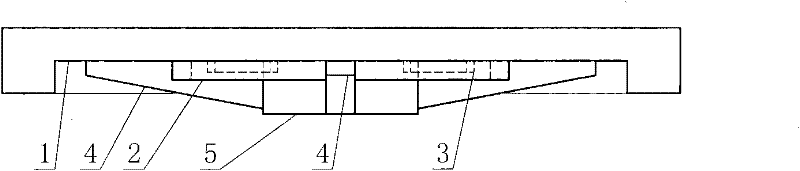

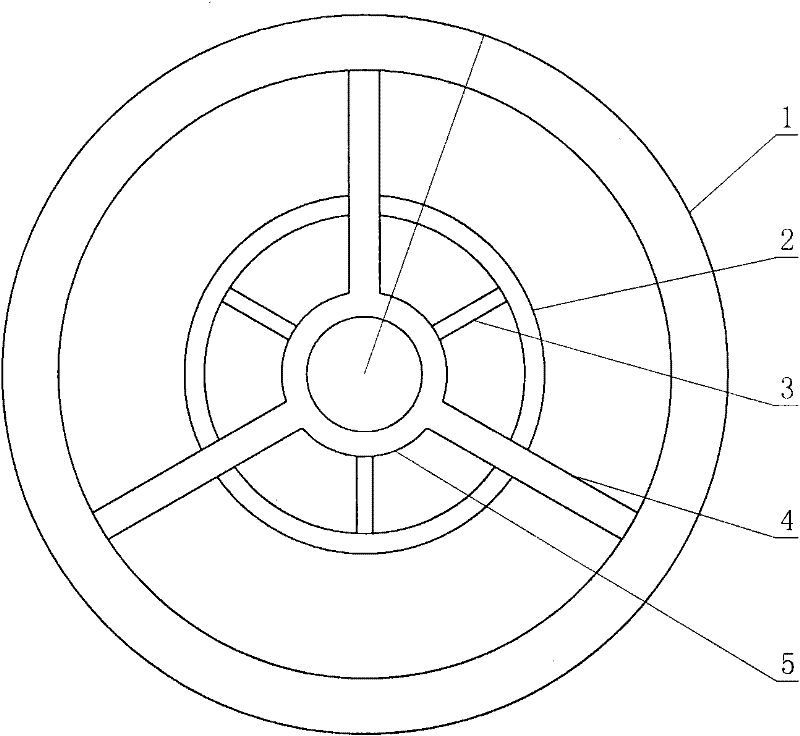

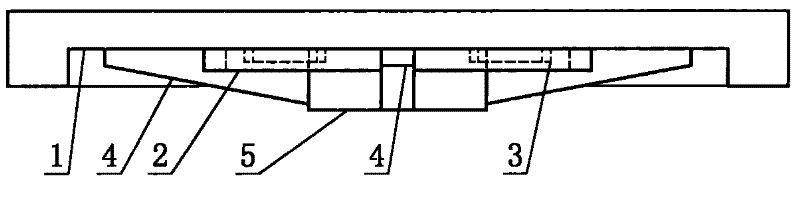

[0012] The ring rib type manhole cover is composed of a cover body 1, an outer ring beam 2, a connecting rib 3, a radial rib 4 and an inner ring beam 5. The outer ring beam 2 , the connecting rib 3 , the radial rib 4 and the inner ring beam 5 are all located on the bottom surface of the cover body 1 and integrated with the cover body 1 . The cover body 1 is a disc body with a circle of downward edges on its circumference. The center of the bottom of the cover body 1 is an annular inner ring beam 5, the inner ring beam 5 is coaxial with the cover body 1 and the outer diameter of the inner ring beam 5 is 1 / 4 of the outer diameter of the cover body 1, and the inside and outside of the inner ring beam 5 The difference in diameter is 5 cm and the thickness is 8 cm. The three radial ribs 4 form an angle of 120° with each other on the plane and connect the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com