Large-span steel connecting bridge and integral hoisting method thereof

A large-span, bridge-connecting technology, applied in the on-site preparation of pillars and building components, construction, etc., to shorten the construction time, overcome the limitations of the construction site, and reduce the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

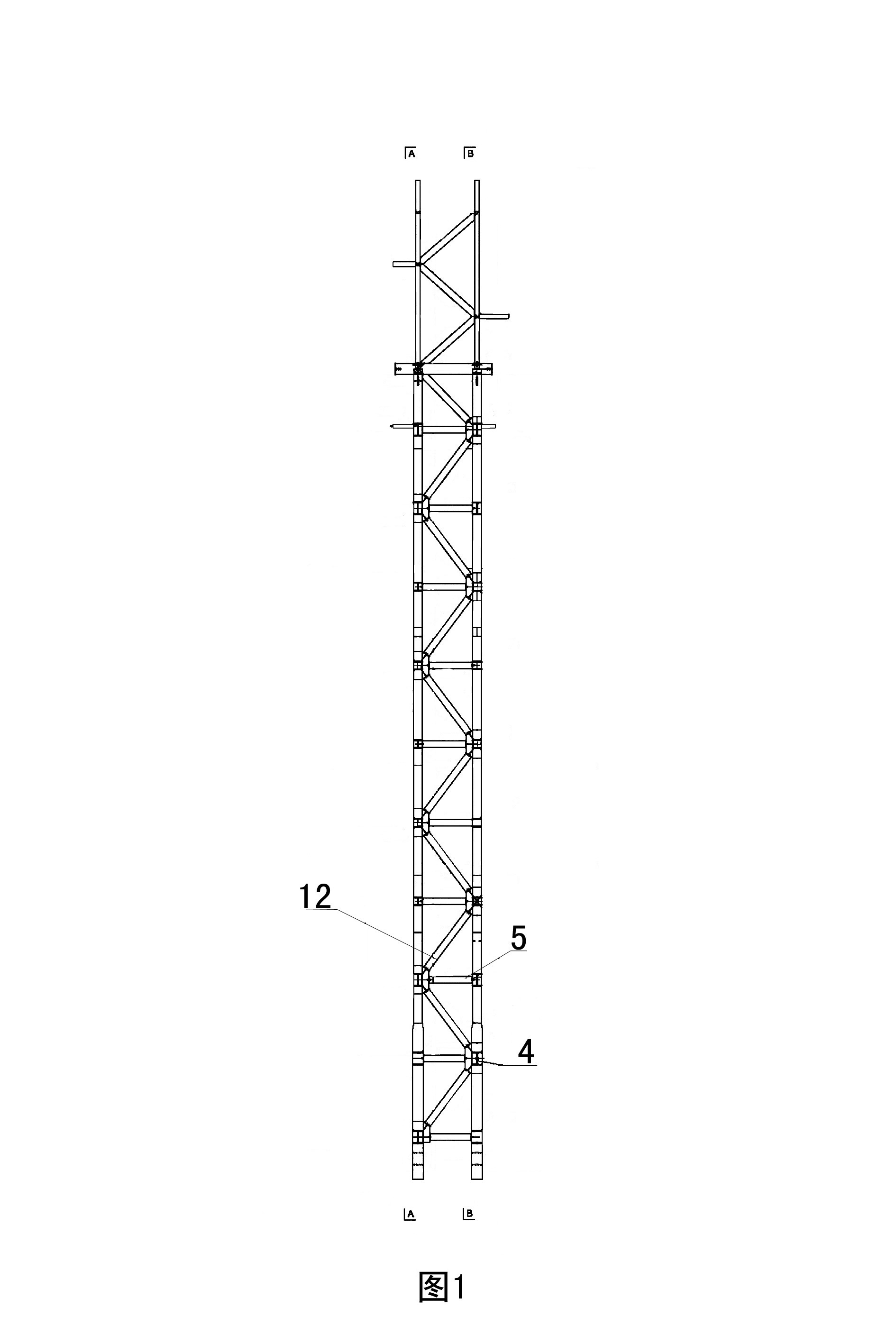

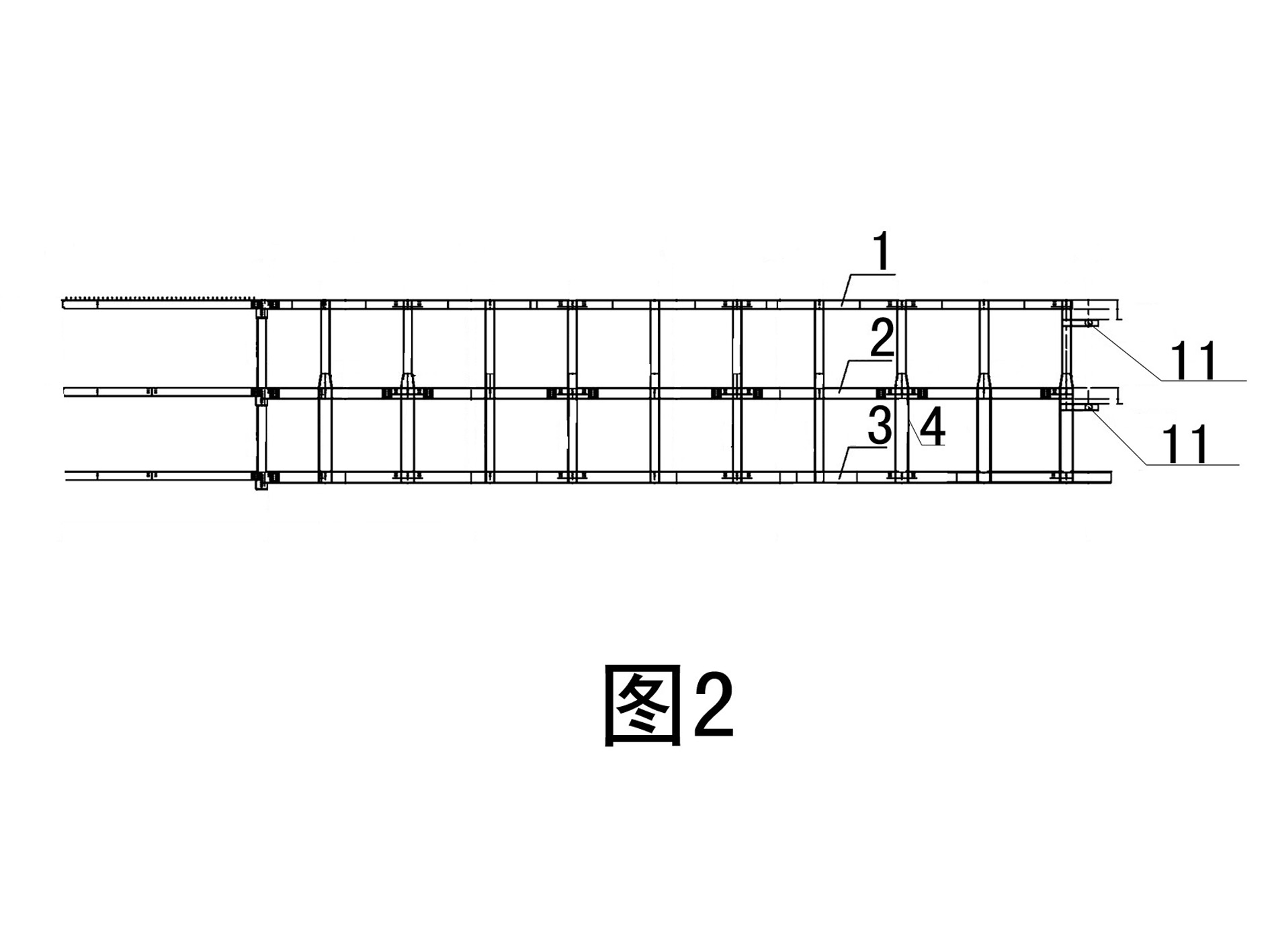

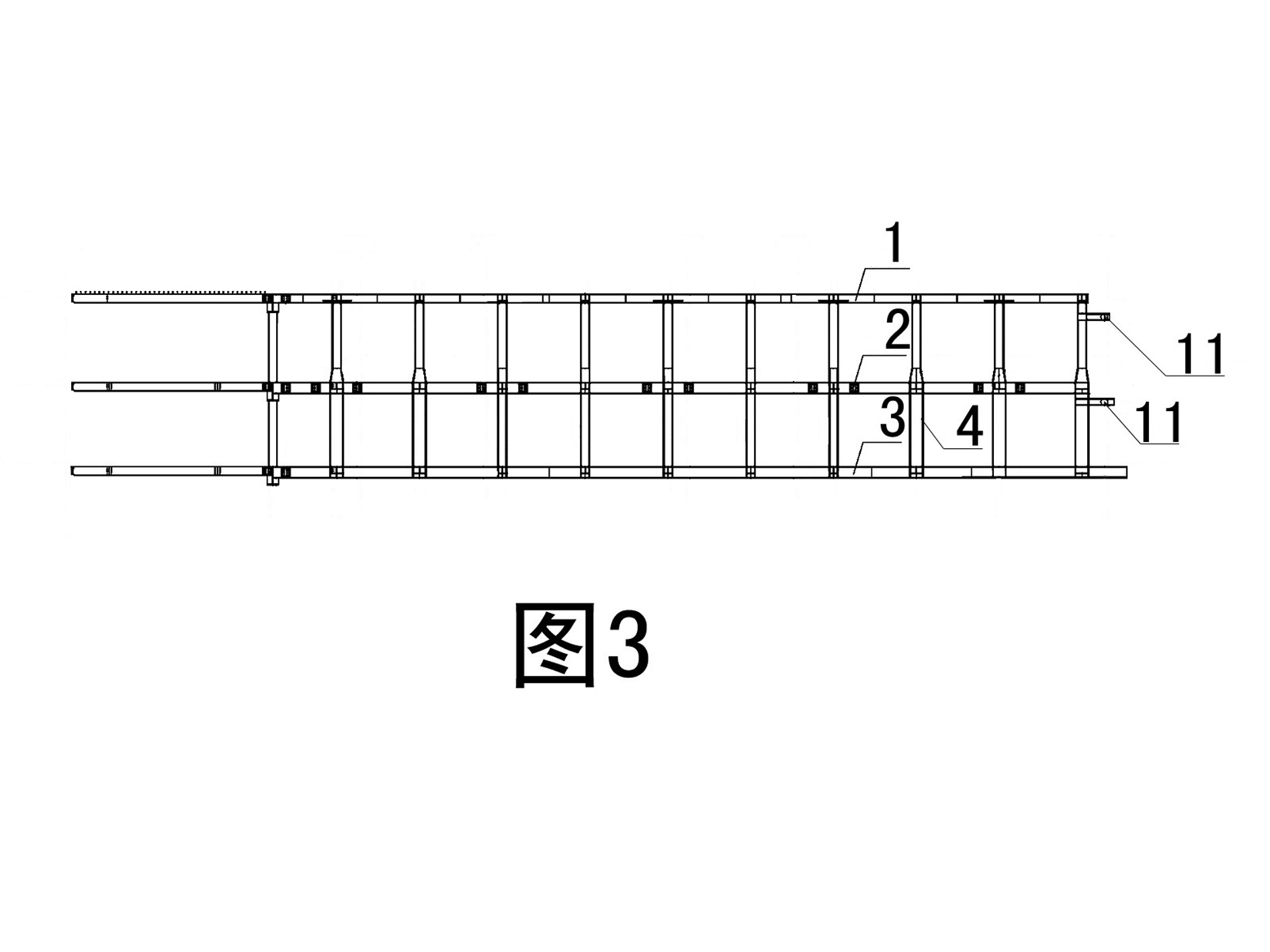

[0036] Examples see Figure 1 to Figure 8 As shown, the first phase and the second phase of an office building are constructed in phases, and the second phase is a new structure. It is necessary to add steel connecting bridges between the eighth, ninth and tenth floors of the original steel structure and the new steel structure (two bridges in total, one in the east and one in the east, symmetrically arranged). Axial dimensions of the bridge: span 36.1m, width 2.7m, height 8.01m, divided into two floors, the bottom elevation is 32.87m, the steel bridge top elevation is 40.880m, and the entire steel bridge weighs about 122 tons. The long-span steel connecting bridge is a steel truss composed of upper chord 1, middle chord 2, lower chord 3, steel column 4 and connecting rods. The connecting rods include horizontal connecting rods 5 and oblique connecting rods 12. One end of the bridge is connected to the new building through high-strength bolts, and the other end is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com