Vertical-axis wind turbine

A wind turbine, vertical axis technology, applied in wind turbines, wind motor combinations, wind turbines at right angles to the wind direction, etc., can solve problems such as poor start-up performance, high noise, and impact on grid-connected electricity prices, and achieve wind speed range acceleration The effect of widening, increasing the sweeping area, and increasing the power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

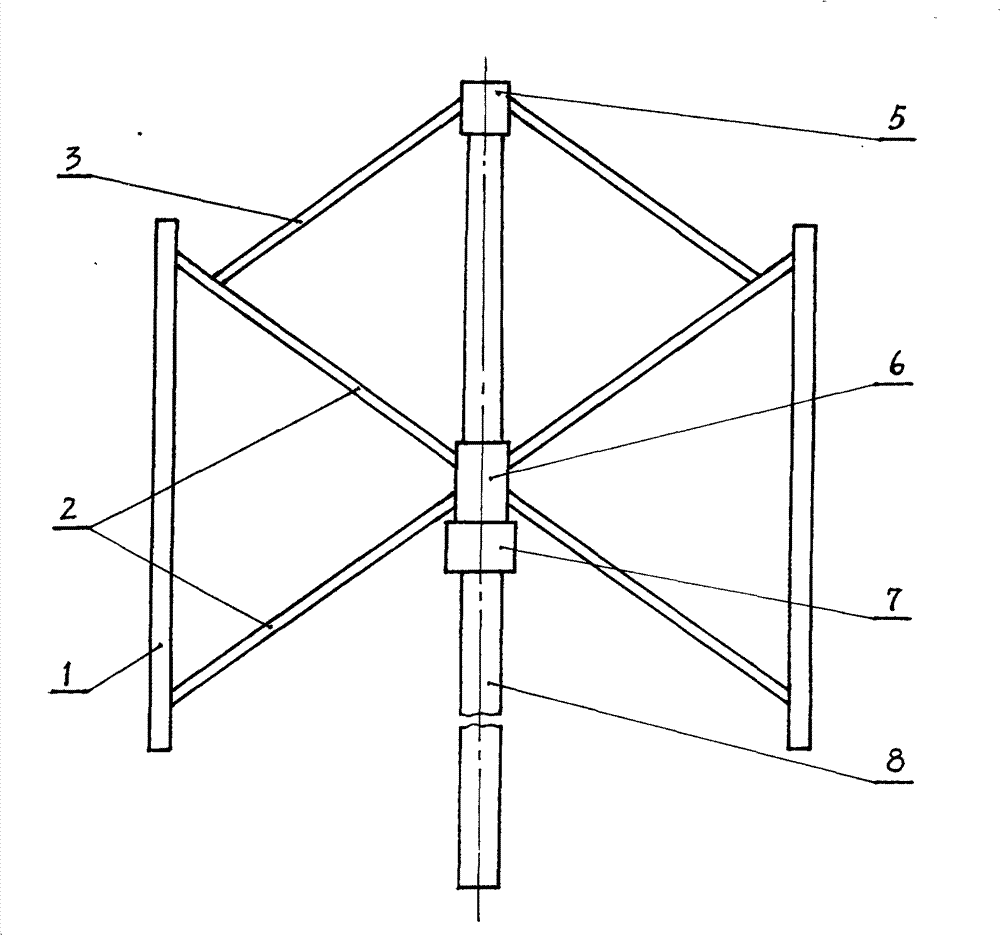

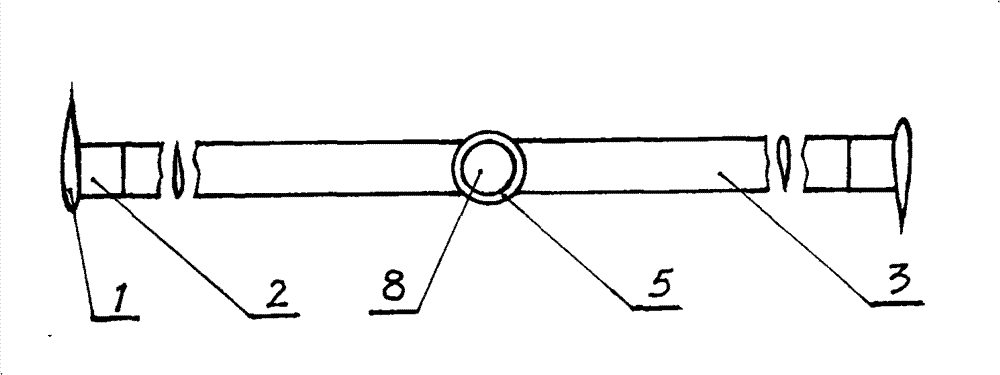

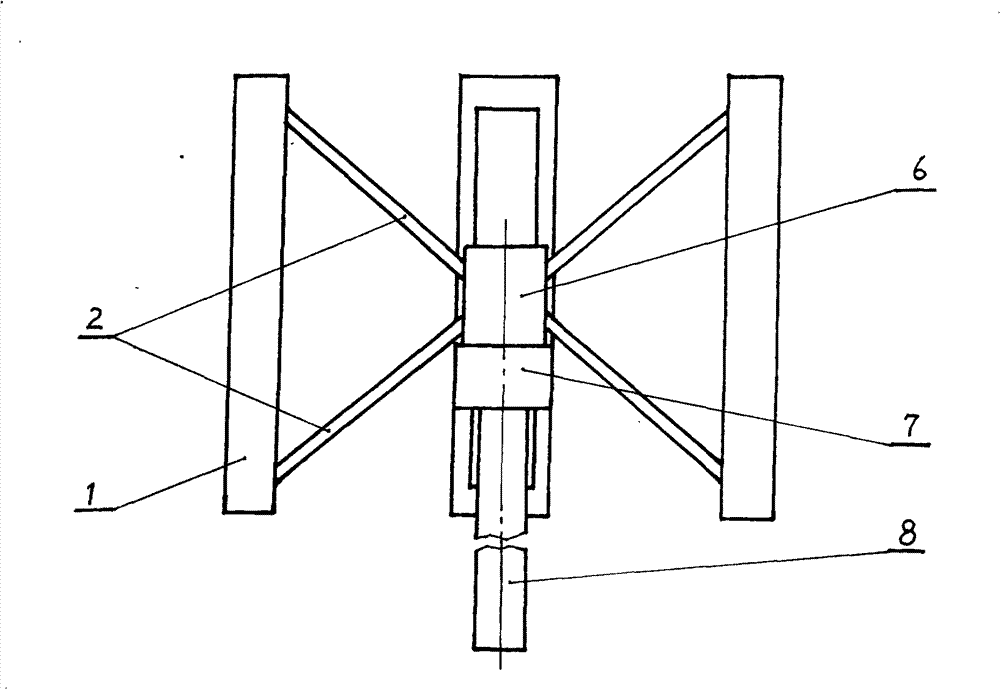

[0017] Referring to the accompanying drawings, a vertical axis wind power generator is mainly composed of a vertical shaft (8) perpendicular to the ground, a generator (7), hubs (5), (6) and blades, and is characterized in that it has a straight airfoil with a certain airfoil. The blades (1) are parallel to the vertical axis and distributed equidistantly around the vertical axis. The connection between the hubs (5), (6) and the straight blades (1) adopts a certain angle with the horizontal direction and has a certain airfoil to generate lift and provide rotational torque. The supporting blade (2), the inclined blade (3).

[0018] The straight blades (1) are connected in a triangle with the supporting blades (2), the obliquely drawn blades (3) and the hubs (5), (6). The included angle between the supporting blade (2) and the obliquely pulled blade (3) and the horizontal direction is about 45 degrees when installed. The straight blade (1), the support blade (2) and the inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com