Driving force transmitting device and vehicle seat slide device

A transmission device and driving force technology, applied in vehicle seats, transmission devices, gear transmission devices, etc., can solve the problems of difficult assembly and assembly work of the driving force transmission device, and achieve fast transportation and storage processing, transportation and storage. Handling easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

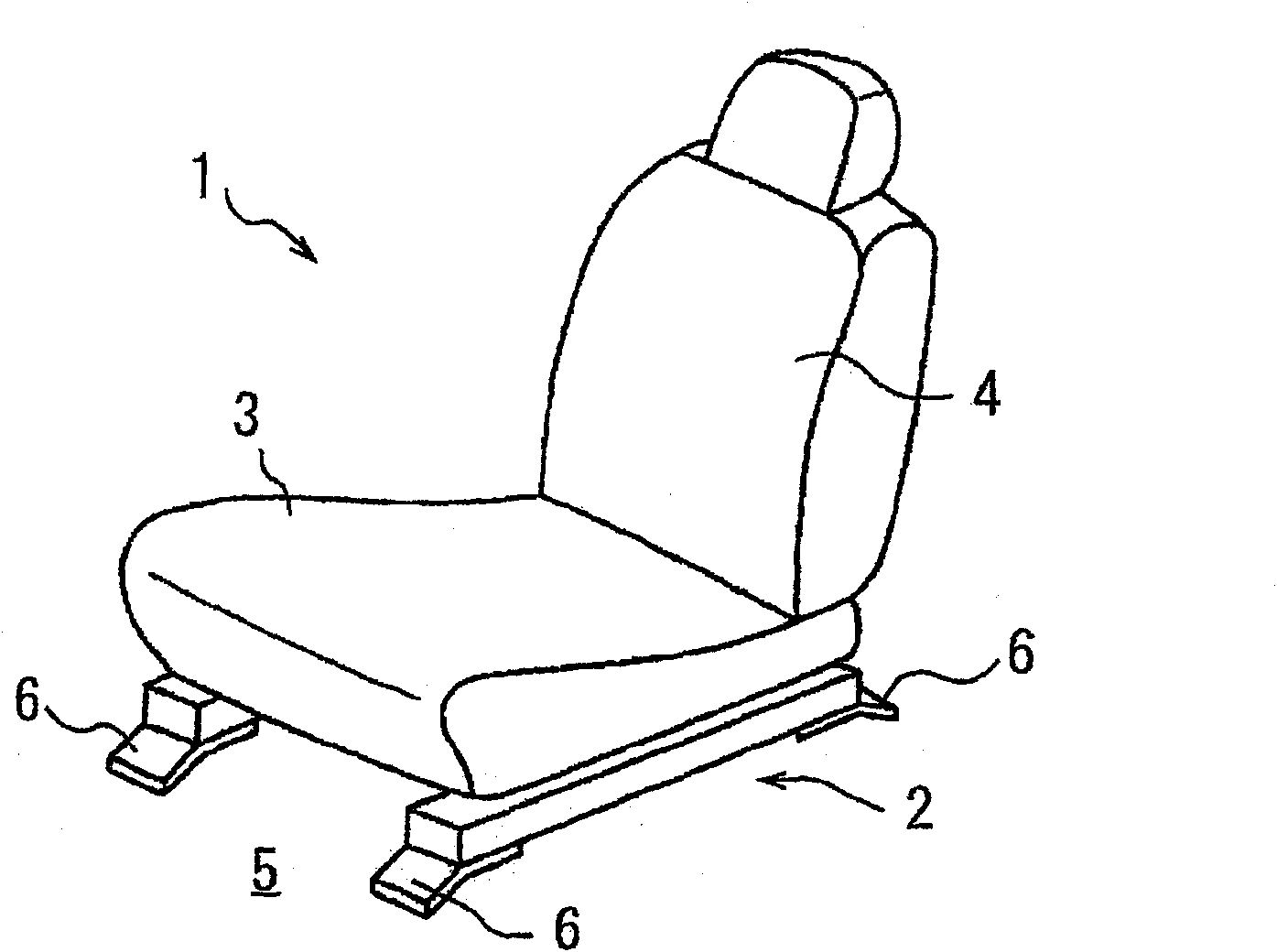

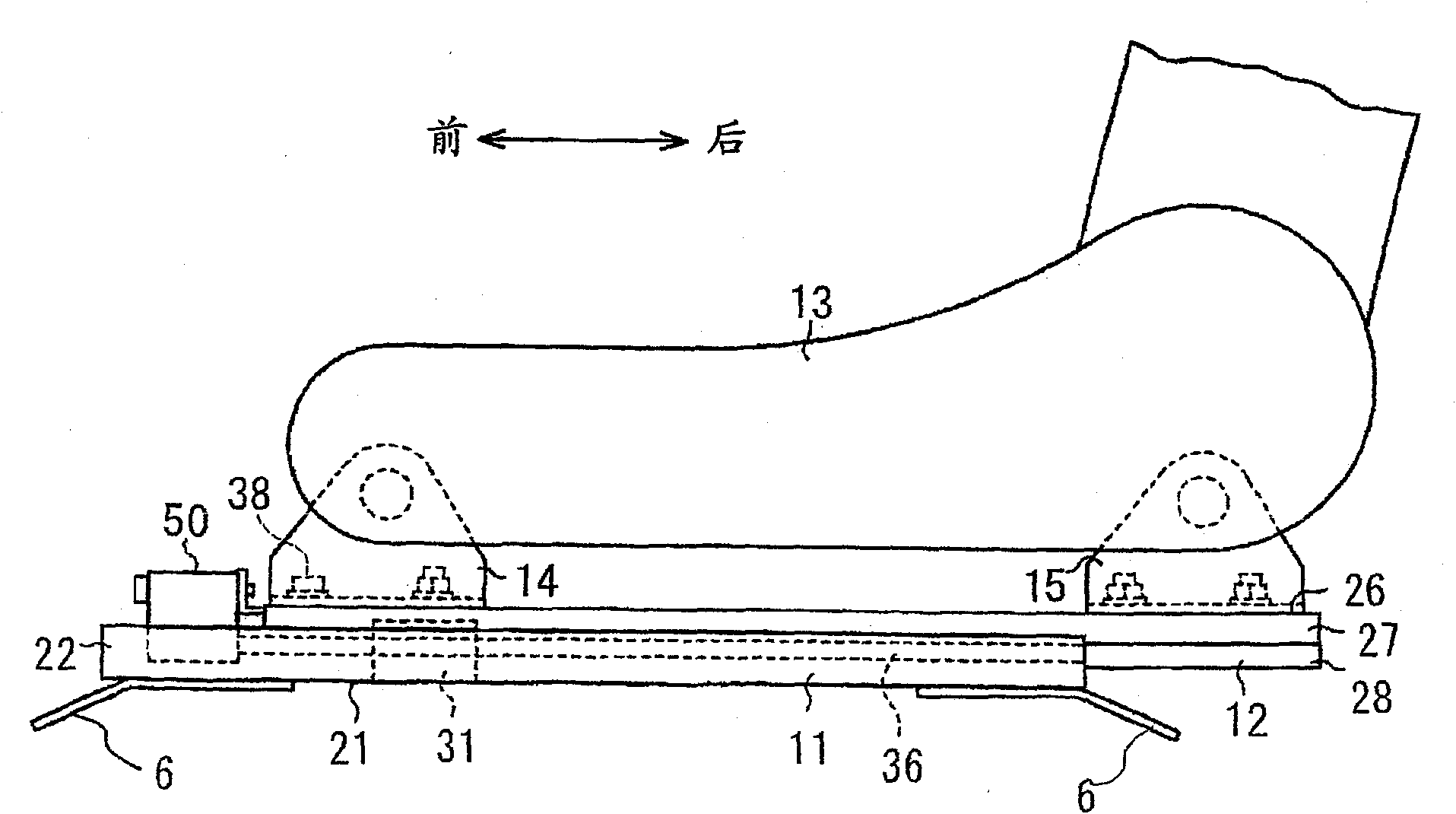

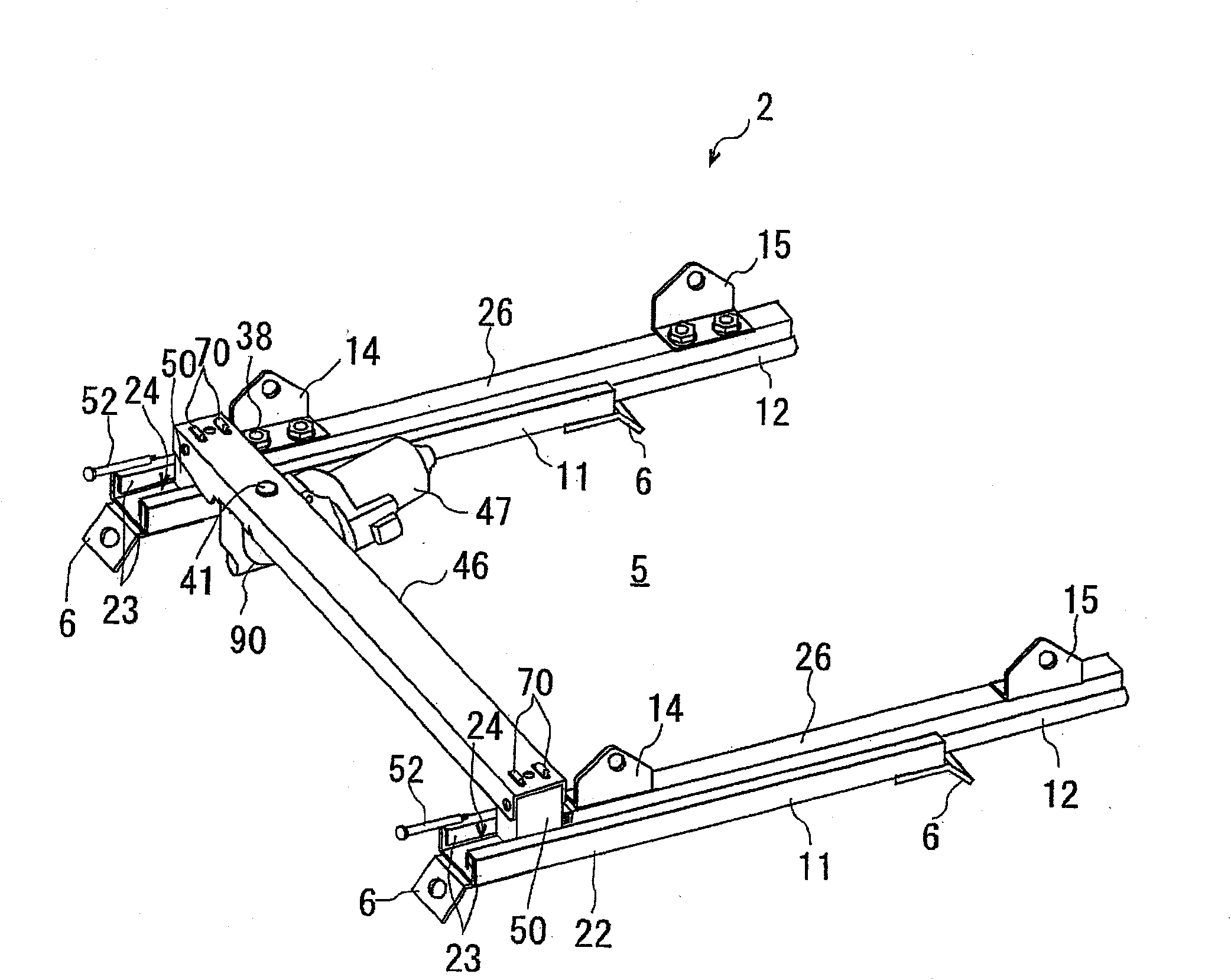

[0037] A driving force transmission device suitable for a vehicle seat sliding device will be described below with reference to the drawings. figure 1 is a perspective view of a seat 1 with a vehicle seat slide 2, figure 2 is a side view of the vehicle seat sliding device 2 . It should be understood that the terms "right and left", "front and rear", "widthwise and axial direction", and "upper and lower" refer to directions or positions relative to the vehicle.

[0038] Such as figure 1 The illustrated seat 1 includes: a seat cushion 3 supported by a vehicle seat slide device 2 and capable of sliding in the front / rear direction relative to a vehicle floor 5; and a seat back 4 supported at a rear end portion of the seat cushion 3 . The vehicle seat sliding device 2 is as figure 2 and 3 The power seat type is shown, and the power seat sliding device 2 includes a pair of lower rails 11, a pair of upper rails 12, a screw shaft 36 as a drive shaft, a nut member 31 (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com