Vehicle headlamp

A technology for headlights and vehicles, applied in vehicle lighting systems, headlights, vehicle parts, etc., can solve the problems of reduced machinability, inconsistent appearance, increased manufacturing costs, etc., and achieves good integrity and improved light efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

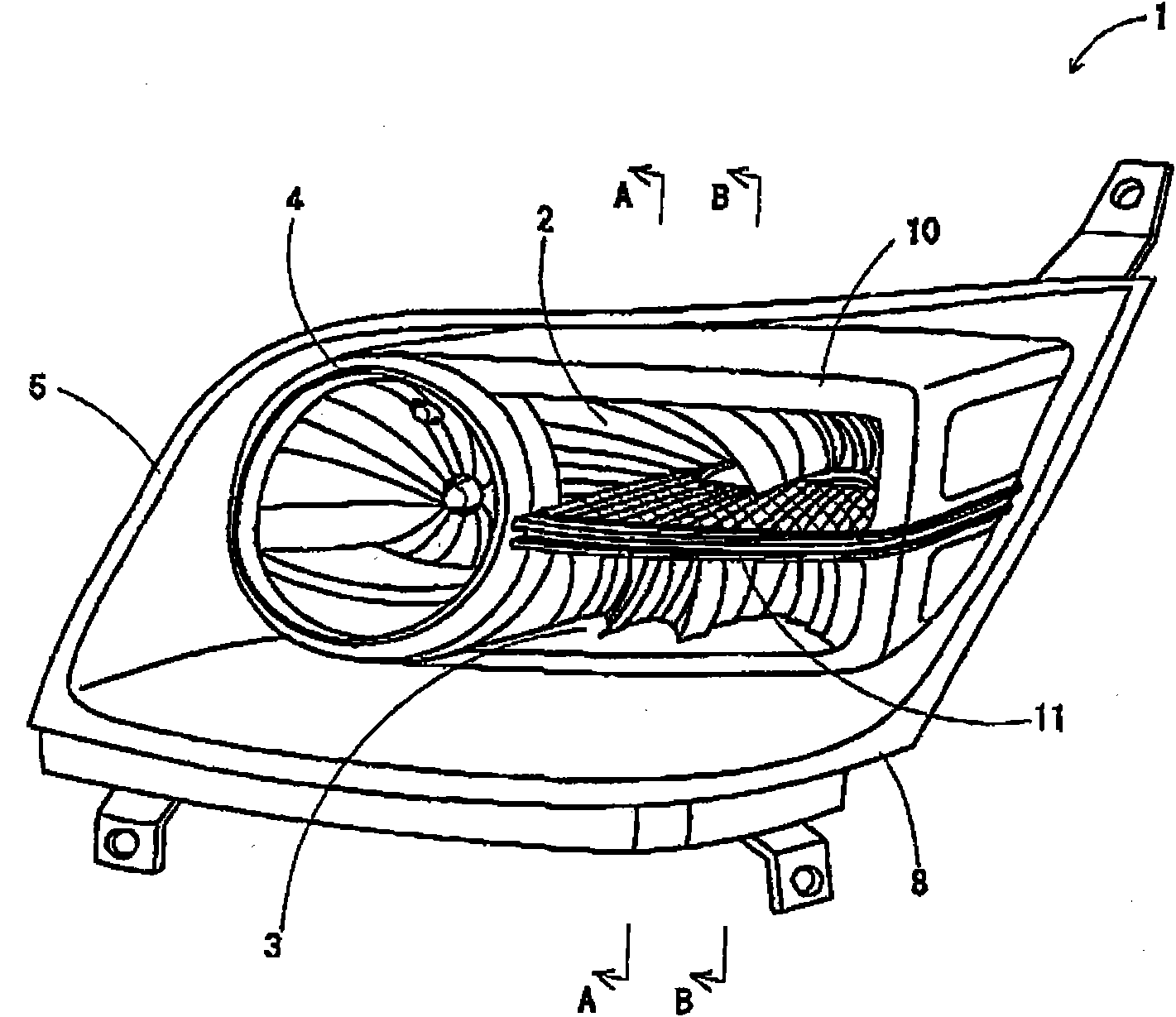

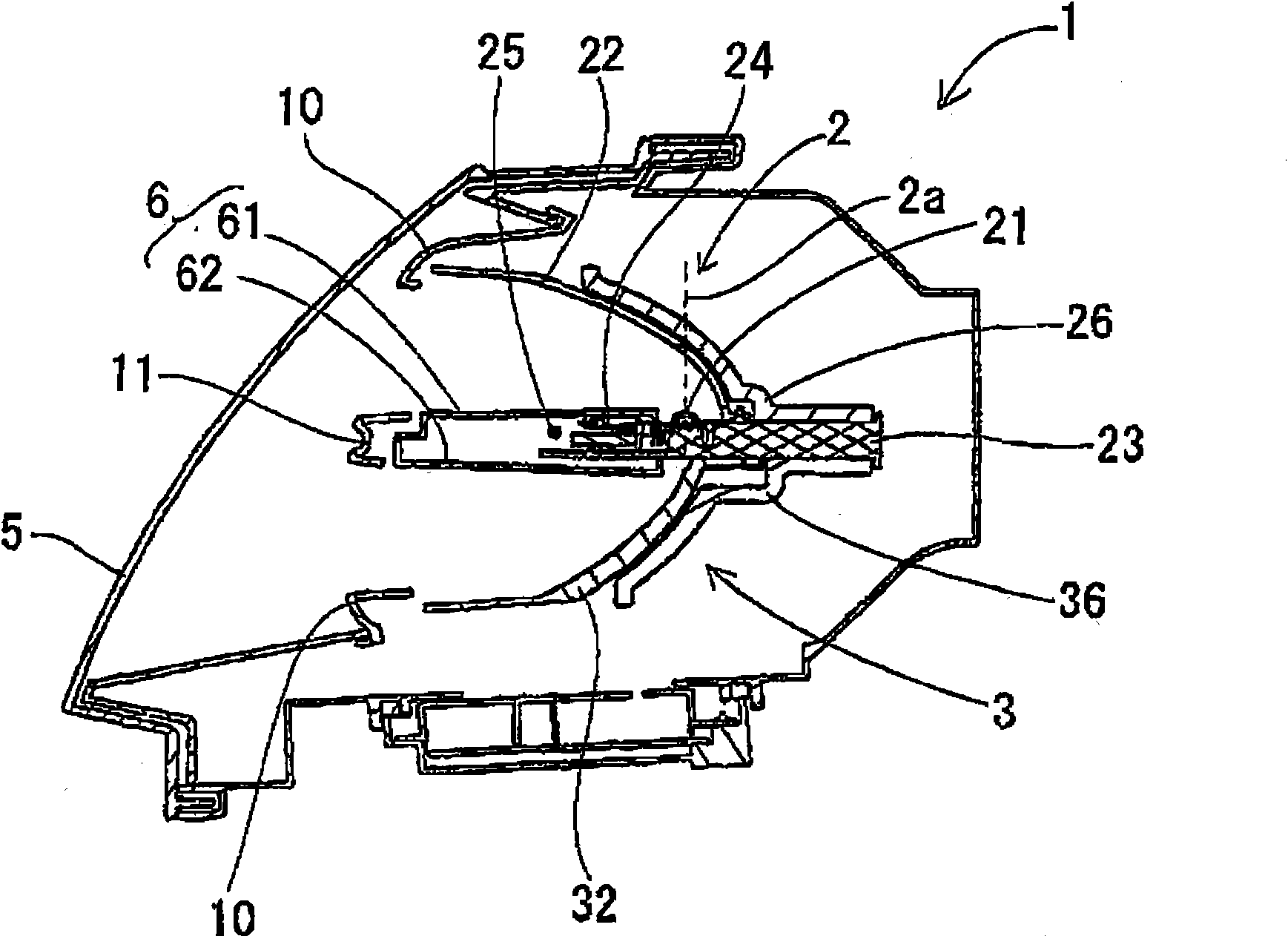

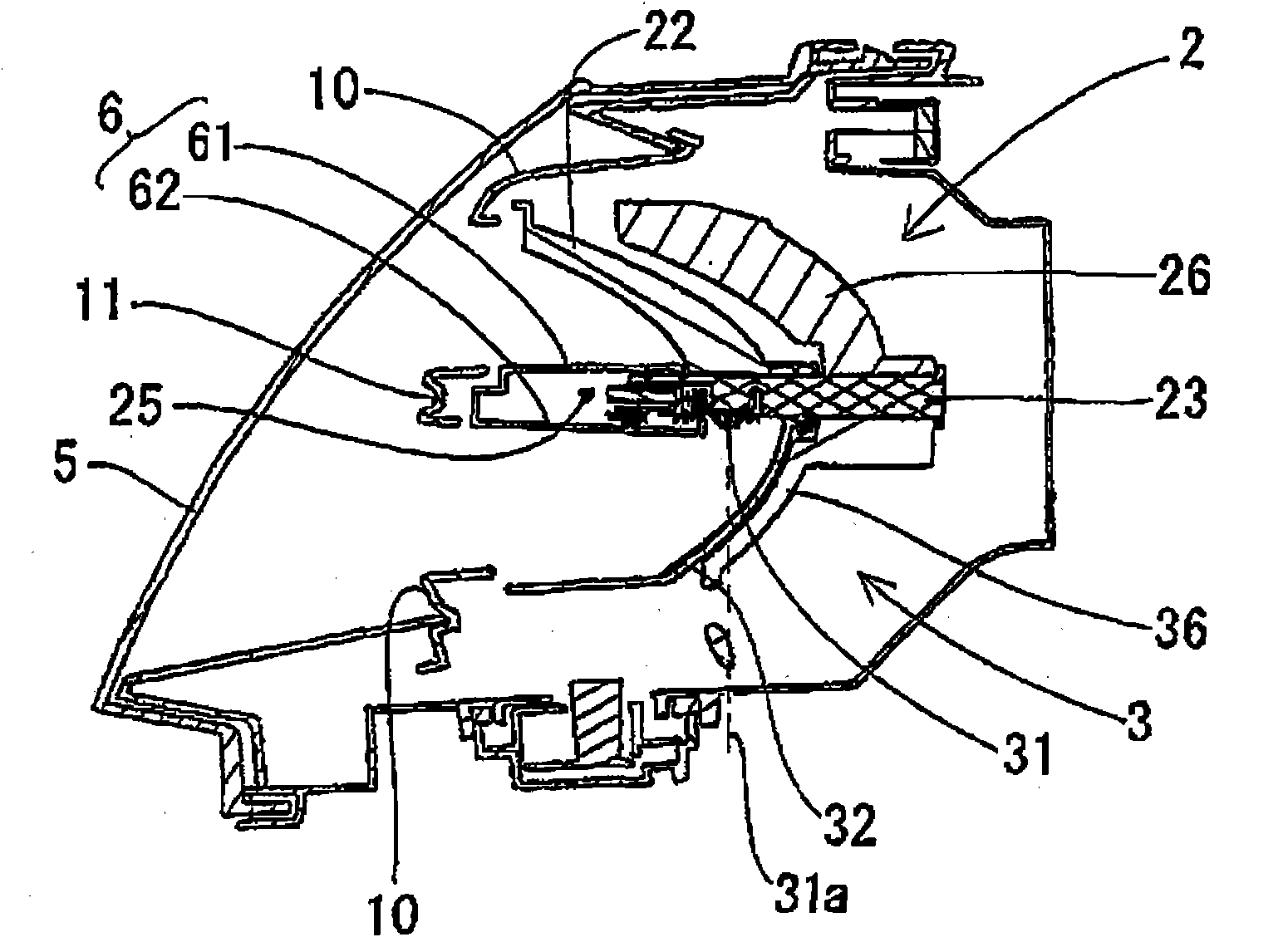

[0014] A vehicle headlamp according to an exemplary embodiment of the present invention is provided with a first low beam member and a second low beam member. The first low beam member and the second low beam member are respectively constituted by reflective light source units. The reflective light source unit is provided with a light source and a reflector, and outputs light by reflecting light emitted by the light source in a predetermined direction with the reflector. As a light source unit different from the reflection type light source unit, there is a projection type light source unit. In addition to the light source and the reflector, the projection light source unit is also provided with a projection lens and a shield. Since the reflection type light source unit does not use a projection lens, the light dissipation of the reflection type light source unit is smaller than that of the projection type light source unit. Therefore, if a reflective light source unit is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com