Evaporative cooling water chiller and mechanical refrigeration high-temperature water chiller compounded water chiller

A chiller and evaporative cooling technology, applied in the field of air conditioning and refrigeration, to achieve the effect of obvious energy saving and improving condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

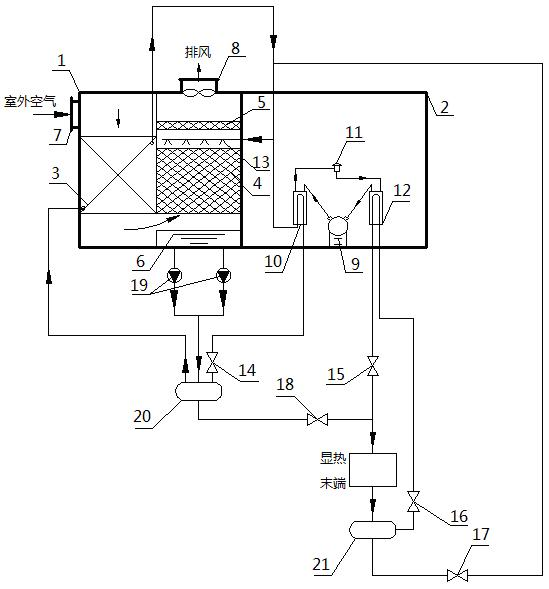

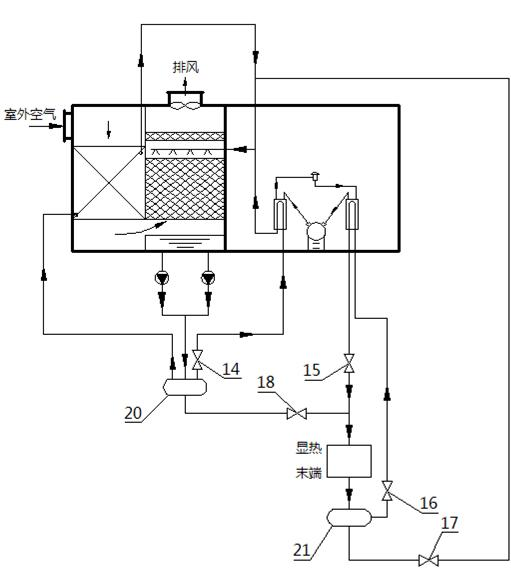

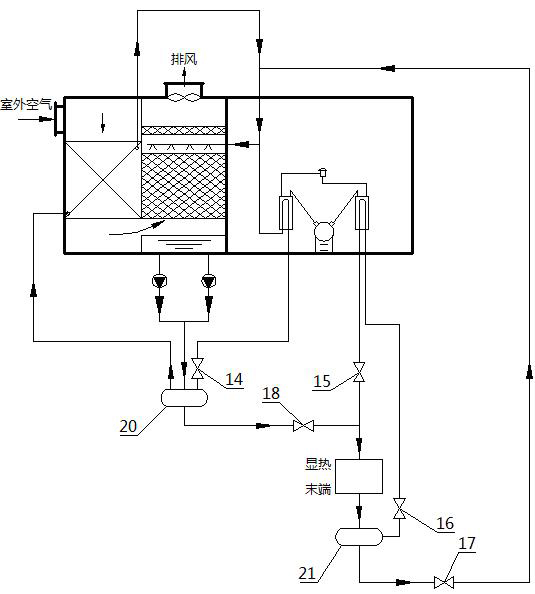

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] The water chiller of the present invention combines the evaporative cooling chiller and the mechanical refrigeration high-temperature chiller. During the operation of the air conditioner, using their respective advantages, when the outdoor air meets the requirements, the evaporative cooling chiller is operated alone to produce sensible heat. The terminal produces high-temperature cold water at 16-18°C; when the weather is not suitable, the whole machine runs, and the mechanical refrigeration high-temperature chiller produces high-temperature cold water for the sensible heat terminal. The evaporative cooling chiller plays the role of a traditional cooling tower, but than cooling towers.

[0022] figure 1 It is an embodiment provided by the present invention that the evaporative cooling chiller and the mechanical refrigeration high temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com